10 Oct 2014

Every year the Seligman APV Trust gives non-UK resident graduates or postgraduates or equivalents with a food engineering background the opportunity to apply for a Seligman APV Award and study at the UK's renowned research centres. The award is named after its founder, Dr Richard Seligman (more information).

Gabriel Finten was awarded the Seligman APV Fellowship for 2014. Here he presents his final report and shares his experiences as a Seligman Fellow.

My UK experience started on 1 March 2014 in Reading where I worked for 6 months under the supervision of Prof. K. Niranjan in the Food and Nutritional Sciences Department (School of Chemistry, Food and Pharmacy- University of Reading). During my stay I studied basic and applied aspects of Food Engineering in order to develop an innovative project with high applicability. The financial support from SCI through the Seligman APV Fellowship was crucial to making this possible.

Research Project: An objective comparison between high hydrostatic pressure and a thermal treatment as blanching methods in leafy vegetables processing

High hydrostatic pressure (HHP) is an innovative and unique technology compared to other food processing technologies as pressure can result in enhancement or retardation of chemical and biochemical reactions as well as in both desired and undesired modification of biopolymers (e.g. enzyme (in) activation, gel formation, etc.). The main application of high pressure in the food industry is for the elimination of pathogens and spoilage microorganisms, and extension of shelf life, it might also keep food properties similar to that of the fresh raw materials.

On the other hand, frozen vegetables are often qualified as fresher than fresh because the vegetables are processed immediately after harvesting (within the first 12 to 24 h) and thus, before any deterioration or oxidation of the vitamins can occur. Before freezing, most of the vegetables are blanched, e.g., treated for a short time (1 to 5 min) in hot water (85– 98°C), to denature enzymes that otherwise could deteriorate nutrients during cold storage. This blanching is especially necessary for vegetables such as spinach, peas and beans that are harvested at high metabolic state. While this thermal treatment leads to some of the favourable factors like inactivation of enzymes, expelling air trapped in the intracellular regions and reduction of microbial load, it also causes loss of nutritional quality. Hence some researchers have suggested HHP as a non-thermal blanching method. The following project takes spinach leaves (Spinacia oleracea L.) as a food model for leafy vegetables.

Novel aspects of the research

As far as we are concerned, HHP has not been studied as a blanching method for leafy vegetables, so baby spinach leaves were proposed in this project due to their high demand and the increasing popularity among these products. Spinach leaf production has increased around 2-fold in the last 10 years in its most important producer, Asian continent, from 2002 to 2012 (above 20 M[t], FAO).

Objective

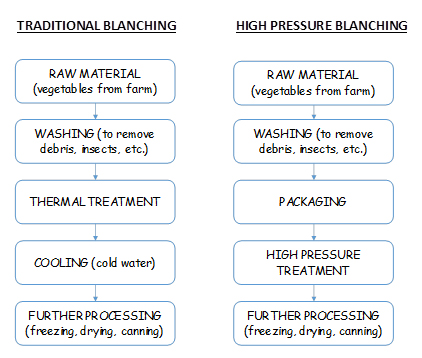

To achieve the replacement of the traditional blanching method for leafy vegetables with boiling water or steam for a high hydrostatic pressure blanching which might have less detrimental effects in the quality properties of the leaves. The spinach subjected to high pressure could be either a final product after proper packaging and refrigerated storage, could be dried, could be canned or could be frozen and commercialised as a frozen product (see Figure N°1).

Figure Nº1: Leafy vegetables flow chart

Possible outcomes:

- HHP processing could be an alternative blanching method for spinach with less detrimental effects either as a pre-freezing step or as a preservation method before packaging.

- HHP processing could preserve nutritional value and the delicate sensory properties of vegetables due to its limited effect on the covalent bonds of low molecular-mass compounds such as colour and flavour compounds.

- The enzymatic browning induced by peroxidases (POD) and polyphenoloxidases (PPO) could be partially or totally inactivated by HHP, thus increasing colour retention properties.

- Antioxidants and carotenoids shouldn´t be affected by HHP (up to 600-700 MPa at ambient temperature) since they are low molecular mass molecules with strong covalent bonds. Neither vitamins nor micronutrients should be affected by HHP.

- The replacement of the thermal blanching by a HHP one could have other benefits such as the following: avoidance of nutrients leaching during the cooling step, usually with cold water which in fact could be a source of pathogens if its safety is not controlled; reduction of water use; and the process could be more efficient in terms of energy demand.

Results

Blanching as a previous step of freezing, drying and canning is done mainly to inactivate enzymes. To evaluate the adequacy of the treatment, the residual activity of peroxidases (POD) was assayed because of its thermal and pressure resistance. It is generally accepted that blanching treatments need to reach 90% of reduction in the activity of target enzymes selected. In addition, the residual activity of polyphenoloxidases (PPO) was also assayed as an indicator of enzymatic browning, one of the causes of loss of acceptance by consumers in spinach.

Spinach leaves were subjected to a wide range of pressures at room temperature (RT, 20ºC), 0-800 MPa for 20 min, since HHP can either activate or inactivate (bio) chemical reactions depending on the process parameters (pressure, time and temperature). POD and PPO activities were assayed and it was found that after 400 MPa (20 min at 20ºC) reductions in enzymatic activity could be reached in both enzymes (data not shown). Different dwell times (from 10 to 60 min) were assayed in the range of 600-800 MPa at RT to evaluate the influence on the selected enzymes inactivation (data not shown). In addition, different temperatures (20, 50, 60 and 70ºC) at 700 MPa for 15 min were also assayed (data not shown).

On the other hand, spinach leaves were subjected to treatments with hot water at 70, 80 and 90ºC for different dwell times (5-15 min, 3-9 min and 0.5-2.5 min, respectively), in order to find which treatments achieve reductions of enzymatic activity equal or greater than 90% (data not shown).

As a result of the latter preliminary treatments the following conditions were selected to compare HHP and thermal treatments in terms of enzymatic activity inactivation and their impact on some quality indices usually followed in leaf y vegetables (antioxidant capacity, total polyphenols content, carotenoids and total chlorophyll content, and instrumental colour):

- 0.1 MPa; 70ºC; 15 min.

- 700 MPa; 20ºC; 15 min.

- 700 MPa; 70ºC; 15 min.

- 0.1 MPa; 90ºC; 30 sec.

- 800 MPa; 20ºC; 15 min.

By comparing treatments 1-3 we can see if there is synergy, in terms of enzymes inactivation and the keeping quality of spinach leaves. Despite the fact that they reached different PPO and POD inactivation levels (see Chart N°1), treatments 4 and 5 were selected, it is interesting to compare the best possible HHP treatment (with the HHP equipment available for this research) at temperatures close to RT with a high-temperature short-time thermal treatment.

Thus by analysing POD and PPO inactivation levels along with quality indices it is possible to consider or discount the likelihood of applying HHP as a replacement for the traditional blanching methods.

Chart Nº1: POD and PPO inactivation achieved by selected treatments (expressed as a percentage of Residual Activity, RA)

Treatment Nº |

P (MPa) |

T (°C) |

t (min) |

RA POD |

RA PPO |

|

1 |

0.1 |

70 |

15.0 |

0.9% |

0.0% |

|

2 |

700.0 |

20 |

15.0 |

27.5% |

15.5% |

|

3 |

700.0 |

70 |

15.0 |

14.9% |

5.0% |

|

4 |

0.1 |

90 |

0.5 |

0.0% |

0.0% |

|

5 |

800.0 |

20 |

15.0 |

27.4% |

17.1% |

Despite the fact that HHP couldn´t achieve 90% reduction in enzymatic activity of the target enzymes due to their extremely high baro-resistance, these treatments still could be successful in terms of extending the shelf life and improving the keeping quality. It is important to take into account other possible benefits of HHP, when considering as a replacement for traditional blanching, such as a high microbial load reduction, however, further studies are needed.

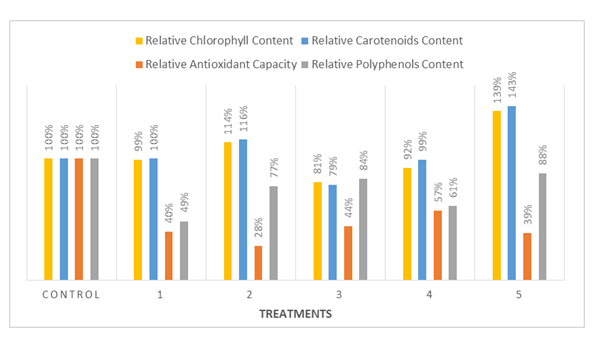

Figures Nº 2 and 3 show how the treatments affected the quality indices when compared with control samples (untreated).

Figure Nº2: Quality indices of baby spinach leaves subjected to selected treatments, expressed as relative contents

Treatments 2 and 5 (at 700 and 800 MPa) showed higher contents of chlorophyll and carotenoids, possibly due to a higher extraction since high pressure damages the cell´s tissues thus facilitating their measurements. The higher the pressure, the higher the extraction of chlorophyll and carotenoids. So, are chlorophyll and carotenoids more available for human intake and absorption? This question can only be answered with further research.

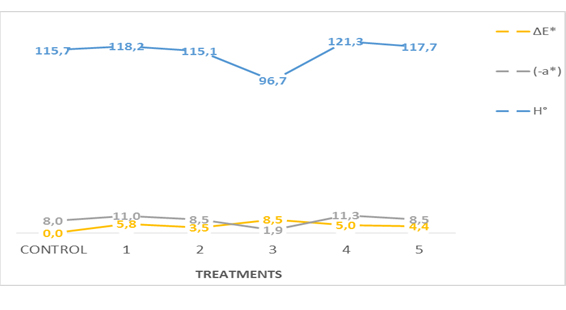

Figure Nº3: Instrumental colour of baby spinach leaves subjected to selected treatments

Instrumental colour can be evaluated with different attributes, for this research the CIELAB parameter a*, the calculated hue angle (H°) and ΔE* (which expresses colour differences when comparing with a standard or a control) were chosen. Hue angles and ΔE* were determined by the following equations:

- H°=180+(tan-1(b*/a*))*(180/π)

- ΔE*=[(Δa*)2 + (Δb*)2 +(ΔL*)2]0,5

The parameter (-a*) indicates the greenness, the higher the value the greener is the colour of the leaves. Values of hue angle around 120° are in accordance with green hues and a decrease in its value indicates that colour is turning into yellow. As it can be seen in Figure N°3, treatment N°3 (high pressure and high temperature) imparted big changes in colour (low (–a*) value, H° value below 100° and high ΔE*), green colour turned into olive green, possibly due to the formation of pheophytins (degradation of chlorophylls). The thermal treatments (N°1 and 4) seem to increase the greenness of leaves showing high values of (–a*) and H°, however this increase is associated with the higher concentration of pigments in the leaves due to water loss (around 25%, data not shown). Finally HHP treatments at RT didn´t affect the colour attributes evaluated.

Key findings

HHP at room temperature could be considered as a non-thermal technology for the blanching process of leafy vegetables. Even though the general accepted criteria for its design was not met (90% of enzymatic activity reduction), it is important to take into account that by subjecting spinach leaves to pressures of 700 and 800 MPa a big reduction of the microbial load would be achieved (another factor in leaves deterioration), according to the findings of other researchers, however, further studies should be done. All the quality indices followed showed that HHP processing at RT had a good performance compared to thermal treatments, nevertheless, this non-thermal technology didn´t show significantly better results on the keeping quality of spinach leaves. Additionally, a high initial investment for the purchase of the high pressure equipment is required.

Future work

Further studies will be necessary to determine if an extension of the shelf-life of HHP treated spinach leaves could be achieved for different final products (frozen, dried, canned or just packed and refrigerated), at different storage conditions. It is also important to evaluate the impact of the treatments on other nutritional indices (vitamin C and folic acid), sensorial properties (consumer's acceptance), microbial load (including tests with pathogens) and nutrients absorption in the gut.

Visits and other events

During the 6 months I stayed in the UK I had the chance to attend several events, short courses and have meetings in some companies and other universities. These events and visits are the following:

- IChemE (Institution of Chemical Engineers) event entitled Challenges in the food industry: a perspective from New Zealand on April 1 2014.

- Committee meeting of the SCI Food Group and evening event Food for thought 2014 on May 20, 2014.

- Campden BRI day, event where the company featured a wide range of interactive exhibits, providing insights in the latest technical developments, it was held on June 11 2014.

- SCI AGM (Annual General Meeting) on July 2 2014.

- Visiting the Department of Chemical Engineering and Biotechnology of the University of Cambridge on July 4 2014, where Dr. Ian Wilson (Reader in Chemical Engineering) introduced me to his PhD students, showed me the facilities of the department, explained to me the research that was being carried out by his group and showed me other interesting parts of the University such as some of the Colleges.

- Meeting with Scott Philips PhD, director of J.W. European Ltd (fresh produce company) on July 16 2014.

- Meeting with Paul Skudder, Global R&D Director at SPX APV, on July 25 2014.

- Workshops at the University of Reading (Researcher Development Programme): Understanding and using images, theory and practice; Presentation skills; How to write a paper; Effective time management; Sourcing information for a literature review; Exploring skills in leadership and influence; Managing data and research material; Managing your research project; An introduction to assertiveness; An essential guide to critical academic writing.

Getting involved with SCI

After being awarded with the Seligman APV Fellowship I became a member of SCI and established contact with the Process Engineering Group (PEG) and the Food Group, which allowed me to take part in the organisation of an evening lecture on my research theme, Postharvest of Horticultural Crops. The evening lecture was held on July 10 2014 under the title: Food security and sustainable production of horticultural crops in the UK, the speaker was Dr. Carol Wagstaff, a knowledgeable and experienced professional in the field. I took a main role in the organisation of this event by selecting the topic, contacting the speaker, and writing the article and synopsis, however, this event couldn´t have been carried out without the great help and collaboration of the PEG and Food Group members as well as the SCI staff.

My Thoughts about my stay in the UK

During the six months I spent in Reading I had the pleasure of meeting wonderful people from all over the world, thus increasing my awareness and knowledge about other countries´ situation in terms of politics, culture, history and economics. Working in an international and highly recognised Research Centre such as the University of Reading has strengthened my interpersonal skills and my technical skills in Food Engineering. On top of the latter, I could visit different cities in the UK (Cardiff, Bath, Bournemouth, London, Brighton, Liverpool, Oxford and Cambridge) getting to know a lot about British culture and history, I became extremely impressed about people´s politeness, the cities amazing organisation and their cosmopolitan populations. To sum up, this experience is one of those I will never forget, and through it I have acquired skills that are going to be very useful in my personal and professional life. In addition, I have extended my network to many countries and I have made friends that I hope to keep for the rest of my life.

Acknowledgments

I am deeply grateful to the SCI Seligman APV Trust for awarding me with the Seligman APV Fellowship, I am really honoured.

Thanks to my supervisor Prof. K. Niranjan for his guidance during my project at the University of Reading and for the kind welcome and farewell. I also want to thank the University of Reading and its staff for providing me with resources and facilities for working pleasantly.

Thanks to the SCI´s staff, Karen Hobbs (Membership Manager) and Emma Thomas (Membership Executive), and thanks to Graham Byars (Chairman of the Seligman APV Trustees and Management Group) who did an excellent job with the organisation and support of the fellowship, and kindly offered their help during my stay.

Thanks to Carlos Harrison and Andy Kerridge for introducing me to the Process Engineering Group and the Food Group, respectively, thanks for their time and help. Thanks to Ester Monfort (Membership Executive) for the help given in the organisation of the event on July 10 2014.

Thanks to Dr. Ian Wilson for kindly showing me the University of Cambridge.

Thanks to my supervisors in Argentina, Dr. Rosa J. Jagus and Dr. M. Victoria Agüero for their support and advice.

Thanks to my new friends in Reading who made the experience more enjoyable. And last but not least, thanks to my family and my girlfriend for all their support and love from a distance during those months.

About me

I am 27 years old and I live in Buenos Aires, but I grew up in one of the southern cities of Argentina (Río Gallegos). I am a graduate in Food Engineering from the University of Cuenca del Plata, in Corrientes (Argentina). Currently I am a doctorate student (Research Fellow) at the University of Buenos Aires and I am carrying out research on non-thermal preservation methods for leafy green vegetables.

My research is focused on developing and optimising innovative preservation methods by applying hurdle technologies to spinach leaves as a model for leafy vegetables, the aim is to improve the keeping quality and extend their shelf life. So far I have applied low doses of gamma irradiations, disinfection washes with citric acid and high hydrostatic pressure as a replacement for the traditional blanching method. In the following years I am planning to combine the latter treatments and other non-thermal technologies not studied yet with the application of natural antimicrobials.

Prior to getting my degree I was a Teaching Assistant in Physics for a semester and I took part in a Research Group in the field of Food Microbiology. I had work placements in a Food Company called Main Process S.A. that processes different kind of fruits, and in a Consultancy Company called Prolatina. After getting my degree I took a year off to study English, travel and work in Canada.

My experience in the Food Industry was as a Plant Manager Assistant in a Rice Mill during 6 months and I was responsible for managing 120 employees at high peak of production and around 70 employees at low peak, scheduling production, controlling critical points in rice processing, assuring GMP and supervising plague control. I left this position to become a Doctorate Student. During the time I worked there I improved my problem-solving and time-management skills.

Besides work and studies, my hobbies are playing football, trekking and playing the guitar. During my stay in Canada I became passionate about Snowboarding. I also like spending time with friends, family and meeting new people.

Gabriel Finten