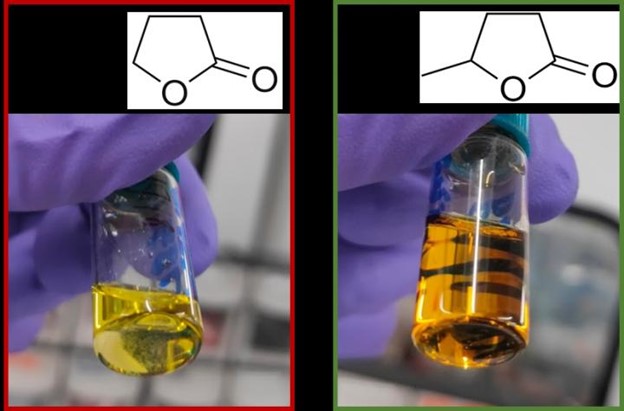

Creating a paper pulp bottle that holds different liquids was a challenge that led BASF to join forces with Pulpex. Using sustainable chemistry the partners came up with an award-winning formula.

-

Vikki Callaghan, Packaging Project Manager, BASF plc

-

Tony Heslop, Senior Sustainability Manager, BASF plc

-

Scott Winston, CEO Pulpex Ltd

Could you start by explaining how the collaboration and the idea for the product came about?

Vikki: We had an existing relationship with Diageo. BASF and The Innovation Team at Diageo had worked on other projects addressing packaging needs. When the team had this idea for an innovative packaging solution they came to us. The challenge put to us was ‘Do you have the chemistry that will hold many different liquids in a paper pulp bottle?’ I love a challenge and was excited to get talking.

Scott: Having worked with BASF before, they were our natural choice to explore this conundrum. Diageo had the idea and an early proof-of-concept of a paper bottle, but it wasn’t utilising sustainable chemistry. The intellectual property was in place but the transformation of scientific proof-of-principle to scaled commercialised technology wasn’t something that could be done alone. The partnership with BASF naturally continued into Pulpex as it formed and continued to grow, remarkably, throughout the Covid-19 lockdown. BASF’s corporate purpose to create chemistry for a sustainable future was intrinsically aligned to meet our need to deliver a commercialisable product that could be produced at scale.

Tony: Following that first call in November 2019, we got together a couple of weeks later and enjoyed an intense deep dive workshop. This was going to take some time but if successful we knew this could be an impactful innovation. We set to work!

Testing out their bottle in the lab. Image courtesy of Pulpex Ltd.

What hurdles did you overcome in the development of the material?

Tony: The obvious hurdle was the pandemic. There were two years between our first and second face-to-face meeting. My initial thought was how do you drive an innovation process when you can’t get together. Surely constructive and productive collaboration isn’t possible? In fact, the inability to travel meant that we could talk more frequently despite our different geographical locations. Once we’d set up weekly online meetings, which evolved into smaller specialist break out groups, the process actually had many positives and the relationships, as well as the innovation, flourished.

Vikki: Of course, as with any innovation, we experienced technical challenges, too. There was no overall solution because we were looking at very diverse requirements and specifications. Different brand owners with different liquids meant there were many considerations and customised solutions required.

Sustainable packaging is a growing market with new products being launched. Can you explain where your product fits in and how is it different from similar materials?

Scott: Pulpex recognises the need to balance three critical aspects. Firstly, new packaging must continue to deliver established brand equity and meet consumer expectations on quality; secondly, any new packaging must technically deliver on performance through the supply chain starting with filling infrastructure compatibility and through distribution and critically, at end-of-life the packaging must be recyclable in existing infrastructure from collection to enable circularity, or where it does unfortunately escape to the environment, it must degrade and not leave an unintended legacy.

Vikki: The resulting fibre bottle is lightweight and offers brand owners a sustainable, environmentally-friendly alternative to plastic and glass bottles.

The final product. Image courtesy of Pulpex Ltd.

What are the main markets for the packaging? Are you able to comment on customers already using your product?

Tony: The innovation will be aimed at brand owners who want to have an alternative sustainable type of packaging, a product that is suitable for ‘on the go’ and that is easily recyclable through existing waste streams. The technology will hold a range of liquids from alcohol and detergent to shower gel, ketchup and engine oil.

Scott: Trials of the finished product have already started to take place with the most recent being at a corporate five-a-side football tournament at Wrexham AFC in May, where several hundred bottles were put to the test working with Severn Dee Water. Branded especially for the event and designed as a keepsake, the feedback from the public was resoundingly positive and it was great to see our bottles in action supporting those on the pitch.

What are the next steps for the BASF/Pulpex collaboration?

Scott: Having developed such a sustainable alternative packaging, our continuing sprint is scaling up! The technology has been developed and we are expecting to have bottles on shelves soon.

Vikki: We will have our ongoing quest of looking to hold a vast range of liquids and for different brand owners. We will have customised solutions, in different sizes, different shapes… the innovation and collaboration continues.

BASF and Pulpex won the SCI Innovation Enabled by Partnership Award 2023. Image credit: Andrew Lunn Photography

Links to previously published articles and videos (BASF/Pulpex/SCI)

- BASF May 2023 – SCI Award

- BASF August 2021 – Collaboration with Pulpex

- SCI News May 2023 – SCI Award

- Pulpex May 2023 – SCI Award

- Pulpex video

Rarely have science and government been as clearly linked as the initial response to the Covid-19 pandemic, when politicians could be heard claiming they were being ‘led by the science’ as often as they could be seen doing that pointing-with-a-thumb-and-fist thing.

This Thursday, the UK’s Chief Scientific Adviser, Sir Patrick Vallance, will receive the Lister Medal for his leadership during the Covid-19 pandemic, and you can stream it live here, exclusively on SCI’s YouTube channel!

In readiness for Sir Patrick’s lecture, Eoin Redahan looks back at three ways science helped to mitigate the spread of Covid-19.

People will never look at vaccine development the same way. For good or ill, we have realised just how quickly they can now be developed. Similarly, we have realised what can be achieved when the brightest brains come together. These are two of the positive legacies from Covid.

But there are others. Some of the innovations conceived to tackle Covid will now tackle other pathogens. Here are just three of the innovations that emerged…

1. Wastewater warning

As Oscar Wilde once said: ‘We are all in the gutter, but some of us are looking up at the genetic material in stool samples.’

Not many people would find inspiration in wastewater treatment plants when thinking about early warning systems for infectious diseases.

Nevertheless, during the Covid-19 pandemic, researchers at TU Darmstadt in Germany came up with a system that detected Covid infection rates in the general population by analysing their waste – a system so accurate they could detect the presence of Covid among those without recognisable symptoms.

To do this, they examined the genetic material in samples from Frankfurt’s wastewater plants and tested them using the PCR test. They claim that their measurement was so sensitive it could detect fewer than 10 confirmed Covid-19 cases per 100,000 people.

It is inevitable that Covid-19 variants will rise again, but this system could alert us to the need for tighter protective measures as soon as the virus appears in our wastewater.

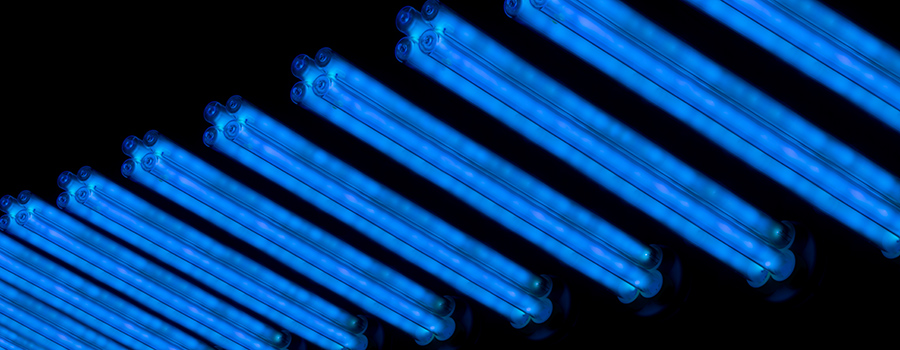

2. UV air treatment

UV light can reportedly reduce indoor airborne microbes by 98%.

Warning systems are important, as are ways to stop the spread of pathogens. To do this, a team from the UK and US shed light on the problem – well, they used ultraviolet light to remove the pathogens.

Using funding from the UK Health Security Agency, Columbia University researchers discovered that far-UVC light from lights installed in the ceiling almost eliminate the indoor transmission of airborne diseases such as Covid-19 and influenza.

The researchers claim it took less than five minutes for their germicidal UV light to reduce indoor airborne microbe levels by more than 98% – and it does the job as long as the light remains switched on.

‘Far-UVC rapidly reduces the amount of active microbes in the indoor air to almost zero, making indoor air essentially as safe as outdoor air,’ said study co-author David Brenner, director of the Center for Radiological Research at Columbia University Vagelos College of Physicians and Surgeons. ‘Using this technology in locations where people gather together indoors could prevent the next potential pandemic.’

3. Biological masks?

‘Physical mask, meet biological mask.’

Many moons ago, it was strange to see a person wearing a mask, even in cities with dubious air quality. Now, they are ubiquitous, and it would appear that mask innovations are everywhere too.

During Covid, researchers from the University of Granada in Spain were aware that wearing masks for a long time could be bad for our health. They devised a near field communication tag for inside our FFP2 masks to monitor CO2 rebreathing. This batteryless, opto-chemical sensor communicates with the wearer’s phone, telling them when CO2 levels are too high.

In the same spirit, researchers in Helsinki, Finland, developed a ‘biological mask’ to counteract Covid-19. The University of Helsinki researchers developed a nasal spray with molecule (TRiSb92) that deactivates the coronavirus spike protein and provides short-term protection against the virus – a sort of biological mask, albeit without those annoying elastics digging into our ears.

‘In animal models, nasally administered TriSb92 offered protection against infection in an exposure situation where all unprotected mice were infected,’ said Anna Mäkelä, postdoctoral researcher and study co-author.

‘Targeting this inhibitory effect of the TriSb92 molecule to a site of the coronavirus spike protein common to all variants of the virus makes it possible to effectively inhibit the ability of all known variants.’

The idea is for this nasal spray to complement vaccines, though during peak Covid paranoia, it might be tricky persuading everyone on the bus that you’re wearing a biological mask.

Covid disrupted scientific progress for many, but as we know, invention shines through in troublesome times. Plenty of innovations such as the ones above will make us better equipped to tackle air borne diseases – alongside the stewardship of leaders like Sir Patrick Vallance.

Watch Sir Patrick Vallance’s talk – Government, Science and Industry: from Covid to Climate – at 18:25 on 24 November

What does clean smell like? What if the fragrance you want to create is that of a sweet-smelling, yet poisonous, flower? In his Scientific Artistry of Fragrances SCITalk, Dr Ellwood led us by the nose.

When Dr Simon Ellwood spoke about creating a fragrance, it sounded like a musical composition or a painting. The flavourist, sitting before a palette of 1,500 fragrance ingredients. Each occupies a different note on the register: the top notes, the middle ones, and the bottom.

To the outsider, this seems impossibly vast and daunting. The Head of Health & Wellbeing Centre of Excellence – Fragrance and Active Beauty Division at Givaudan mentioned that Persil resolved to come up with ‘the smell of clean’ for its detergents in the late 1950s.

But what should clean smell like? Should it be the green, citrusy aromas of this laundry detergent, the smell of mint, or the antiseptic at the hospital?

To make choosing smells slightly less daunting for flavourists and perfumers, they are at least split into odour families such as citrus, floral, green, fruity, spicy, musky, and woody. Some of these ingredients are natural, some are inspired by nature, and others come from petrochemicals and synthetic materials.

The delicious-smelling musk deer.

Deer gland perfume

One of the smells you may have sprayed on your person – one sibling in this odour family – has peculiar origins. The pleasant, powdery smell known as musk was originally extracted from the caudal gland of the male musk deer and from the civet cat.

But as the Colognoisseur website notes, as many as 50 musk deer would have to be killed to obtain one kilogramme of these nodules. Now, killing a load of deer and cats for a few bottles of perfume may not have seemed unethical several centuries ago, but it also wasn’t sustainable or cost-effective. It became clear that a synthetic musk was needed.

When the synthetic musk discovery came in 1888, it was a chance discovery. Albert Bauer had been looking to make explosives when a distinctive smell came instead, along with the scent of opportunity.

>> Read about the science behind your cosmetics

Dior recreated the woodland notes of Lily of the valley.

Do you like the smell of jasmine?

Dr Ellwood’s talk laid bare not only the vastness of everything we smell, but also the ingenuity of those who recreate these odours. In terms of breadth of smell, neroli oil – which is taken from the blossom of a bitter orange – has floral, citrus, fresh, and sweet odours, with notes of mint and caraway. Similarly, and yet dissimilarly, jasmine’s odour families are broken down into sweet, floral, fresh, and fruity, and – jarringly – intensely fecal.

The ingenuity of flavourists is exemplified by lily of the valley. The woodland, bell-shaped flowers are known for their evocative smell, but all parts of the plant are poisonous. Despite this, French company Dior synthetically recreated the lily of the valley smell in its Diorissimo perfume in 1956 using hydroxycitronellal, which is described by the Good Scents Company as having ‘a sweet floral odour with citrus and melon undertones’.

Cyanide smells like almonds, but you might not want to eat it.

Of course, as Dr Ellwood noted, synthetic flavours can only ever get so close to the real thing – an imperfect facsimile. However, the mere fact that chemists have recreated deer musk, lily of the valley, and the prized ambergris from sperm whales to create the fragrances we love is almost as extraordinary as the smells themselves.

‘Fragrance,’ he said, ‘will always be the confluence of the artistry of the perfumer and the chemist.

Register for our free upcoming SCI Talk on the Chemistry behind Beauty & Personal Care Products.

Little machines that blend makeup tailored for your skin alone… Technology that details the tiny creatures walking on your face… The cosmetic revolution is coming, and Dr Barbara Brockway told us all about it.

Max Huber burnt his face. The lab experiment left him scarred, and he couldn’t find a way to heal it. So, he turned to the sea. Inspired by the regenerative powers of seaweed, he conducted experiment after experiment – 6,000 in all – until he created his miracle broth in 1965. You might know this moisturiser as Crème de la Mer.

A rocket scientist in the world of cosmetics seems strange, but when you interrogate it, it isn’t strange at all. As Dr Barbara Brockway, a scientific advisor in cosmetics and personal care, explained in our latest SCItalk, cosmetics hang from the many branches of science.

Engineering, computer science, maths, biology, chemistry, statistics, artificial intelligence, and bioinformatics are among the disciplines that create the creams you knead into your face, the sprays that stun your hair in place. They say it takes a village to raise a child, and it takes an army of scientists to formulate all the creams, gels, lotions, body milks, and sprays in your cupboard.

Some say sea kelp can be used to treat everything from diabetes, cardiovascular diseases, and cancer, to repairing your nails and skin.

There is a reason why the chemistry behind these products is so advanced. If you sell bread, it is made to last a week. If you make a moisturising cream, it is formulated to last three years. To make sure it does that, chemists test it at elevated temperatures to speed up the time frame. They conduct vibration tests and freeze-thaw tests to measure its stability.

Dr Brockway likened the process of bringing a product to market to a game of snakes and ladders. If you climb enough ladders, you could take your own miracle brew to market within 10 months.

But expectations are high, and the product must delight the user. Think of the teenager who empties a half a can of Lynx Africa into his armpit, or the perfume that is a dream inhaled. Each smell she likened to a musical composition.

But these formulators are not struggling artists. Perfumers and cosmetic chemists – these bottlers of love and longing and loss – can earn a fortune. Dr Brockway’s quick calculation provided a glimpse of the lucre.

Take 15kg of the bulk cream you mixed on your kitchen table. That same cream could be turned into 1,000 15ml bottles, each sold for £78. So, just 15kg of product could fetch £78,000. So, it’s easy to see why the global beauty market is worth $483 billion (£427 billion), with the UK market alone worth £7.8 billion – more than the furniture industry.

Smart mirror, mirror, on the wall…

It’s unsurprising that an industry of such value and scientific breadth embraces the latest technologies, from those found in our phones to advances in genetics and the omics revolution.

Already, the digital world has left the makeup tester behind. Smart mirrors overlay virtual makeup, recommend products for your complexion, and even detect skin conditions. Small machines that look like coffee-makes blend bespoke makeup. Indeed, Dr Brockway noted that Yves Saint Laurent has created a blender that produces up to 15,000 different shades.

Even blockchain has elbowed into the act. It is being used to make sure that a product’s ingredients aren’t changed in between batches. By showing customers every time-stamped link of the supply chain, companies can prove that their products are organic or ethically sourced. The reason why blockchain is significant here is that, once recorded, the data stored cannot be amended.

At first glance, proving the provenance of materials to customers might seem like a marketing ploy, but this is also being done in response to the increasing fussiness of the consumer.

Collagen is the main component of connective tissue.

Dr Brockway said all brands are now under pressure to incorporate sustainability into their business practices. The younger age group is also looking for more organic, vegan-friendly ingredients, and businesses have had to respond.

For example, microbial fermentation is being used instead of roosters’ coxcombs to create hyaluronic acid. Similarly, Geltor claims to have created the first ever biodesigned vegan human collagen for skincare (HumaColl21®). Such collagen is usually provided by our friends the fish.

These advances are significant, certainly to the life expectancies of roosters and fish, but of such ingredients revolutions are not made. Other forces will shake the industry.

Meditating on omics

Back in the 1970s, scientists thought the microbes that live on our skin were simple, but next-generation DNA technology reveals that thousands of species of bacteria live on our skin (a pleasant thought). Dr Brockway says these microbes tell us about our lifestyles – to the point that they even know if you own a pet.

So, what is the significance of this? Developments in DNA technology and omics (various disciplines in biology including genomics, proteomics, metagenomics, and metabolomics) mean we can now get not just a snapshot, but an entire picture of what’s going on on your face.

‘Thanks to omics we really know what’s now going on with our skin and see what our products are doing,’ Dr Brockway said. ‘We know the target better. We know which collagens, out of the 263, we need to encourage.’

We are learning more and more about how our skin behaves. And those time-honoured potions and lotions espoused by our grandparents – it will make sense soon, not just why they work, but why they work for some and not for others. In cosmetics, we are leaving the era of checkers and entering the age of chess.

This is the first of three cosmetic SCItalks between now and Christmas. Register now for the Scientific artistry of fragrances.

In his winning essay in SCI Scotland’s Postgraduate Researcher competition, Alexander Triccas, postgraduate chemistry researcher at the University of Edinburgh, explains how the tiny shells produced by marine algae protect our natural environment.

Each year, SCI’s Scotland Regional Group runs the Scotland Postgraduate Researcher Competition to celebrate the work of research students working in scientific research in Scottish universities.

This year, four students produced outstanding essays. In the fourth of this year’s winning essays, Alexander Triccas explained how coccoliths provide a valuable carbon store and could play a key role in keeping our bones healthy.

Why tiny shells produced by marine algae are important for both global carbon stores and repairing bones

Although humans can engineer complex and eye-catching structures that help us navigate through our daily lives, they are nowhere close to the design and functionality of natural materials.

These mineral structures are specifically grown to provide support, protection, or food for many organisms. Humans would not exist without them. Indeed, our bones and teeth are made of calcium phosphate. But when grown in a lab, calcium phosphate forms as simple rectangular crystals, which is vastly different to how our bones and teeth look.

This is because our bodies use organic molecules to precisely control how minerals grow, producing materials that can fulfil very specific tasks. Biominerals can even be produced inside single cells. Coral reefs are held together by calcium carbonate minerals made by marine invertebrates. Elsewhere in the ocean, carbonate shells produced by small algae cells are buried on the ocean floor, over time forming the chalk rocks that make up coastal landmarks such as the White Cliffs of Dover.

Advances in microscopy are shedding new light on the composition of coccoliths.

This process is incredibly important to the environment. It takes carbon dissolved in seawater, turns it into solid material, then stores it at the bottom of the ocean. It is concerning then that we don’t know how ocean acidification and rising CO2 levels will affect coccoliths, the name given to these carbonate shells.

>> SCI’s Scotland Group connects scientists working in industry and academia throughout Scotland. Join today!

We’re still unsure how coccoliths are produced, particularly how organic molecules are used to give them their unique shape. Proteins and sugars decide where and when the first carbonate mineral forms; then the growth of the coccolith is controlled by sugar molecules.

But how exactly do these organic molecules control the mineral that is produced? We struggle to answer this question because we don’t know how the composition of the coccolith changes as the structure grows.

Composition of the coccolith

Our research focuses on imaging coccoliths in an attempt to observe these changes. We used a technique called X-ray ptychography to map coccolith composition over the course of its formation. This revealed that coccoliths are not entirely made of calcium carbonate, instead having a hybrid structure containing mineral and organic molecules. But this isn’t all.

We revealed that the composition of the coccolith changes during its growth. We think this could represent a transition from a disordered liquid-like state to an ordered crystalline state. While this is common in other biomineral-produced organisms like corals, no evidence of this transition has been reported in coccolith formation before.

>> Read Rebecca Stevens’ winning essay on PROTAC synthesis.

This is incredibly important because it tells us how the cell is controlling the first calcium carbonate mineral that forms. The transition enables the cell to control exactly how it wants the mineral to form, meaning coccoliths can be made faster.

It might also lessen the impact that more acidic seawater has on mineral formation. This could mean coccoliths will not be affected by ocean acidification as much as expected, which is good for the planet’s long-term carbon stores.

However, this is only a prediction. Improvements to the microscopes used to analyse coccoliths will help us know if the transition occurs. Electron and X-ray microscopes are extremely useful in industry – from drug research and medical imaging, to data storage and materials analysis – but their use in these fields is still relatively novel.

Coccolith analysis could give us a better idea of how bones are produced.

Most advancements in instrumental procedures are done in academic research. Our work, therefore, helps us understand the benefits and limits microscopes may have, making them more suitable for industrial use.

Bone research also relies heavily on these microscopes. Our findings could be important in understanding how bones are produced, benefiting not only pharmaceutical and medical industries, but also improving human healthcare by providing better treatments to patients.

In her winning essay in SCI Scotland’s Postgraduate Researcher competition, Marina Economidou, first year PhD Student at GSK/The University of Strathclyde, talks about palladium recovery.

Each year, SCI’s Scotland Regional Group runs the Scotland Postgraduate Researcher Competition to celebrate the work of research students working in scientific research in Scottish universities.

This year, four students produced outstanding essays in which they describe their research projects and the need for them. In the second of this year’s winning essays, Marina Economidou explains the need for palladium recovery and making it more efficient.

Pictured above: Marina Economidou

U-Pd-ating the workflows for metal removal in industrial processes

Palladium-catalysed reactions have great utility in the pharmaceutical industry as they offer an easy way to access important functional motifs in molecules through the formation of carbon-carbon or carbon-hetero-atom bonds.

The superior performance of such reactions over classical methodologies is evident in modern drug syntheses, where Buchwald-Hartwig, Negishi or Suzuki cross-coupling reactions are frequently employed.

However, the demand for efficient methods of palladium recovery runs parallel to the increased use of catalysts in synthesis. The interest in metal extraction can be attributed to several reasons.

Cross-coupling steps are usually situated late in the synthetic route, resulting in metal residues in the final product. In addition to possessing intrinsic toxicity, elemental impurities can have an unfavourable impact on downstream chemistry.Hence, their limit must be below the threshold set by the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH).

The need for palladium recovery

However, the importance of palladium recovery does not only arise from the need to meet regulatory criteria. The volatility of palladium supply as a result of geopolitical instabilities has been a focus of attention this year, with Russia producing up to 30% of the global supply and prices reaching an all-time high of £81,179 per kilogramme.

Therefore, aside from the need to remove metals from the product for regulatory reasons, there is a desire to recover metals from waste streams as effectively as possible due to their finite nature and high costs.

The sustainability benefits of recovery for circular use are an additional incentive for an efficient extraction process, as catalysts can be regenerated when metal is returned to suppliers.

The increasing pressure for greener processes and more ambitious sustainability goals – such as GlaxoSmithKline’s environmental sustainability target of net zero impact on climate by 2030 – also contribute to the need for further refinement of working practices.

>> SCI's Scotland Group connects scientists working in industry and academia throughout Scotland.

Palladium has many uses including in catalytic converters, surgical instruments, and dental fillings.

Improving extraction processes

It is essential to have well-controlled and reproducible processes for pharmaceutical production, as redevelopment requires further laboratory work and additional time and resources.

With several industry reports on the inconsistent removal of palladium following catalytic synthetic steps, there seems to be a knowledge gap as to which factors affect the efficiency of extraction and why there can be significant differences between laboratory and plant conditions.

The focus of my PhD is investigating the speciation of palladium in solution in the presence of pharmaceutically relevant molecules, to offer an insight into the efficiency of metal extraction at the end of processes.

By understanding the oxidation state and coordinative saturation of the palladium species formed in the presence of different ligands, a better relationship could be established between the observed performance of metal extraction processes under inert and non-inert conditions.

With the wide breadth of ligands and extractants that are now commercially available for cross-coupling reactions, my ambition is to generate a workflow for smart condition selection that not only achieves selective metal recovery, but is scalable and can be transferred to plant with consistent performance.

The cost and preciousness of metal catalysts are both factors that prohibit their one-time use in processes. Understanding how palladium can be extracted and recovered in an efficient manner will not only deliver reliable processes that meet the demands of the market in the production of goods, it will also lead to economic and environmental benefits.

>> Read Angus McLuskie’s winning essay on replacing toxic feedstocks.

>> Our Careers for Chemistry Postdocs series explores the different career paths taken by chemistry graduates.

The Commonwealth Games has landed in Birmingham. Before the Games began, viewers were treated to an extraordinary opening ceremony (featuring a giant mechanical bull) and its artistic director, Iqbal Khan, was lauded for his ingenuity.

But such ingenuity shouldn’t surprise any of us, for Birmingham has long been a place of outsized invention. For more than 300 years, the inhabitants of this industrial powerhouse have churned out invention after invention; and its great pragmatists have turned patents into products.

Chemistry, too, owes a debt to the UK’s second city. Whether it’s the first synthesis of vitamin C, the invention of human-made plastic, adventures in mass spectrometry, or electroplated gold and silver trinkets, Birmingham has left a lasting legacy.

Here are five chemists whose innovations may have made an appearance in your life.

Alexander Parkes – man of plastic

Plaque commemorating Alexander Parkes in Birmingham, England. Image by Oosoom

Look around you. Look at the computer screen, the mouse button you click, and the wire casings everywhere. Someone started it all. That man was Alexander Parkes, inventor of the first human-made plastic.

The son of a brass lock manufacturer from Suffolk Street, Birmingham, Parkes created 66 patents in his lifetime including a process for electroplating delicate works of art. However, none were as influential as the 1856 patent for Parkesine – the world’s first thermoplastic.

Parkes’ celluloid was based on nitrocellulose that had been treated by different solvents. In 1866, he set up the Parkesine Company at Hackney Wick, London, but it floundered due to high cost and quality issues. The spoils of his genius would be enjoyed by the rest of us instead.

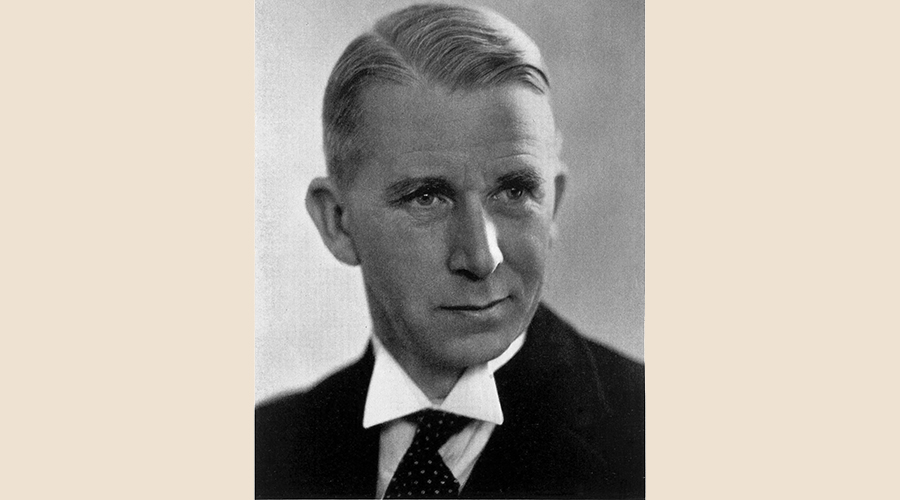

Sir Norman Haworth – the vitamin seer

Sir Norman Haworth

Sir Norman Haworth may have been born in Chorley, Lancashire, but his finest work arguably came after he became Director of the Department of Chemistry in the University of Birmingham in 1925. Haworth is famous for his groundbreaking carbohydrate investigations and for being the first to synthesise vitamin C.

By 1928, Haworth had confirmed the structures of maltose, cellobiose, lactose, and the glucoside ring structure of normal sugars, among other structures. Apparently, his method for determining the chain length in methylated polysaccharides also helped confirm the basic features of starch, cellulose, and glycogen molecules.

However, Haworth is most famous for determining the structure of vitamin C and for becoming the first to synthesise it in 1932. The synthesis of what he called ascorbic acid made the commercial production of vitamin C far cheaper – the benefits of which have been felt by millions of us.

For his achievements in carbohydrates and vitamin C, Haworth received the Nobel Prize for Chemistry in 1937 (shared with Paul Karrer). He was the first British organic chemist from the UK to receive this honour. Haworth even had a link to SCI, having been a pupil of William Henry Perkin Junior in the University of Manchester’s Chemistry Department.

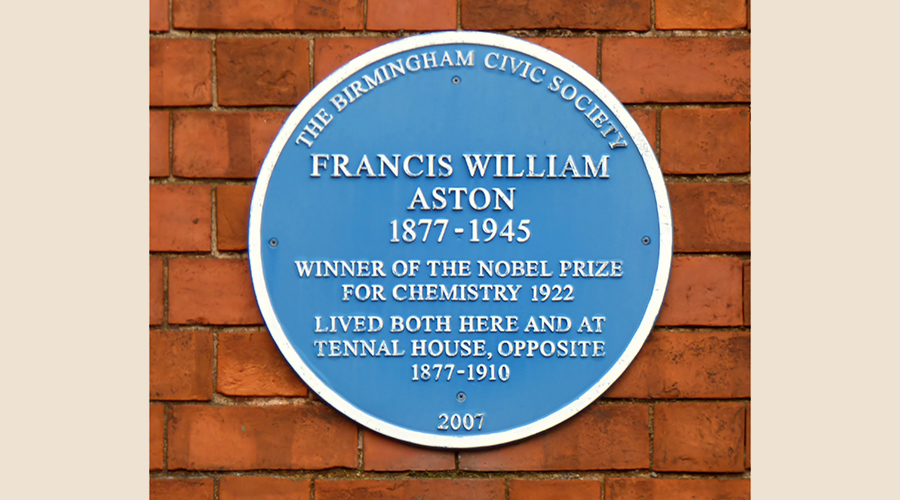

Francis William Aston – adventures in mass spectrometry

Blue plaque for Francis William Aston. Image from Tony Hisgett

Another Nobel Prize-winning chemist from Birmingham is Francis William Aston. The Harborne native won the 1922 prize for discovering isotopes in many non-radioactive elements (using his mass spectrograph) and for enunciating the whole number rule.

For a time, academia almost lost Aston, as he spent three years working as a chemist for a brewery. Thankfully, he returned to academic life and obtained concrete evidence for the existence of two isotopes of the inert gas neon before the first World War.

After working for the Royal Aircraft Establishment during the Great War (1914-18), he resumed his studies. The invention of the mass spectrograph proved pivotal to his discoveries thereafter. Using this apparatus, he identified 212 naturally occurring isotopes.

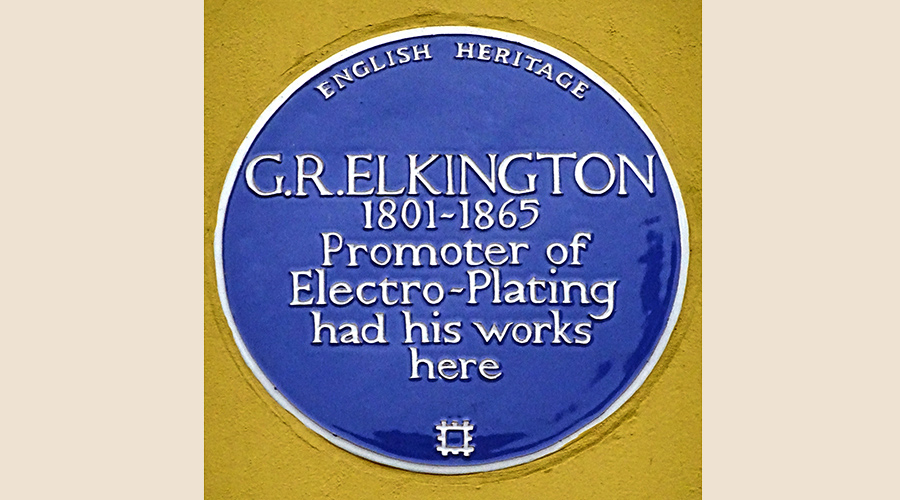

George Elkington and John Wright – all that glitters

George Elkington patented the electroplating process developed by John Wright. Image from Spudgun67

It isn’t surprising that George Elkington should become an SCI favourite, as he blended both scientific ingenuity with business. The son of a spectacle manufacturer patented the first commercial electroplating process invented by Brummie surgeon John Wright in 1840.

Wright discovered that a solution of silver in potassium cyanide was useful for electroplating metals. Elkington and his cousin Henry purchased and patented Wright’s process before using it to improve gold and silver plating.

The Elkingtons opened an electroplating works in the city’s now famous Jewellery Quarter where they electroplated cutlery and jewellery. And they didn’t do too badly out of it. By 1880, the company employed 1,000 people in seven factories.

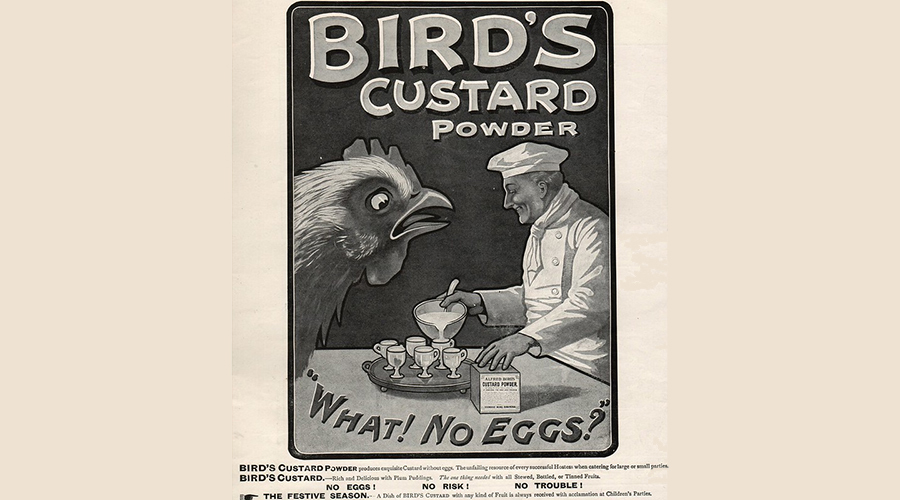

Alfred Bird – winging it

1906 advertisement for Birds Custard powder. Image from janwillemsen

In 1837, Alfred Bird was in a pickle. He wanted to serve his dinner party guests custard, but his wife was allergic to eggs and yeast, and egg was the main thickening agent of this delicious gloop.

Instead of serving something else, the chemist shop owner invented his own egg-free custard by substituting cornflour for eggs. His guests found it delicious and Bird’s Custard was born.

Not content with this innovation, Bird is also credited with being the father of modern baking powder. Once again, his wife’s allergies were said to be the inspiration, as he wanted to create a yeast-free bread for her. In bread and custard, true love always finds a way.

By rethinking the way our products are designed and changing the way we use plastics, we can tackle the blight of marine litter and the general accumulation of plastic waste. But, as Professor Richard Thompson said in our latest SCItalk, systemic issues and historical excesses have made this no easy task.

Contrary to popular perception, plastic is not the villain. When it comes to marine littering, we are the ogres, with our single-use bottles bobbing in the oceans and the detritus of our everyday lives littering the coastline.

We are the reason why 700 species are known to encounter plastic debris in the environment. It is because of us that plastics have beaten us to the bottom of the deepest oceans and glint in the sun near the summit of Mt. Everest.

According to Richard Thompson, of the Marine Institute School of Biological and Marine Sciences at the University of Plymouth: ‘Plastic debris is everywhere. Its quantity in the ocean is likely to triple between 2015 and 2025.’

As Professor Thompson pointed out all of these facts to his audience in our latest SCItalk on 23 March, he outlined potential solutions. However, there is no ignoring the depth of the issues at hand when it comes to the litter in our seas.

The problems

1 - The weight of history

Society has gradually woken up to the menace of discarded plastics and, laterally, to the threat of microplastics and nanoplastics. The problem is that we left the barn door open decades ago. So, all of those plastic microbeads from shower gels, fibres from clothing, and tyre wear particles polluted our seas for many years before it came to public and scientific attention.

Professor Thompson said that 300 papers were published globally on microplastics in the last academic year alone, but research in the area was relatively thin on the ground before Thompson and his colleagues released their pioneering study on microplastics in Science in 2004.

2 - Bad habits

‘The business model for the use of plastics hasn’t really changed since the 1950s,’ Professor Thompson said. According to him, we have had 60 years of behavioural training to just throw products away, and our waterways reflect this attitude.

According to Professor Thompson, 50% of shoreline litter items recorded during the 2010s originated from single-use applications. Without a sea change in our attitude towards single-use items, this problem will persist.

>> Why are we ignoring climate change and what can we do about it? Read more on our blog post.

Microplastics have been subject to great scrutiny, but much of the research is quite recent.

3 - We need to talk about nanoplastics

The problems with larger plastics and even microplastics are now well documented. The worrying thing, according to Thompson, is that there are knowledge gaps when it comes to nanoplastics in the natural environment. What are the effects of nanoplastic ingestion? What are the effects of human health? Time will tell, but Thompson was keen to ask if we really need that information before we take action.

He was more sanguine about the effects of microplastics. ‘The concentration of microplastics is probably not yet causing widespread ecological harm,’ he said, ‘but if we don’t take measures, we’ll pass into widespread ecological harm within the next 50-100 years.’

The solutions

It seems counterintuitive to think of petrochemical plastics as a sustainable solution; and yet, despite the environmental problems posed by their durability, they do have a role to play in a greener approach.

‘If used responsibly, plastics can reduce our footprint on the planet,’ Thompson noted. Indeed, the lightweight plastic parts in our cars and in aviation can actually help reduce carbon emissions. But despite their merits, how do we keep plastic litter from our seas?

1 - Design for end of life… and a new one

To illustrate a flaw in the way we design plastic products, Professor Thompson gave the example of an orange coloured drinks bottle. While the bright colour may help sell juice drinks, there is an issue with recycling these coloured plastics because their value as a recyclate is lower. Clear plastics, on the other hand, are much more viable to recycle.

He argues that many products aren’t being designed with the whole lifecycle in mind. ‘We’re still failing to get to grips with linking design to end of life,’ he said, before highlighting the importance of communicating how products should be disposed of right from the design stage.

Basically, our products should be designed with end of life in mind. ‘If we haven’t even designed a plastic bottle properly,’ he lamented, ‘what hope do we have with something that’s more complicated?’

Those brightly coloured plastic bottles look nice and fancy, but they can be challenging to recycle in a circular economy.

2 - Ever recycle? Ever fail? Recycle again. Recycle better

Professor Thompson argued that better practices are needed to help divert materials away from our seas (and it should be noted that there are other types of discarded materials to be found there). If we recycle greater quantities of end of life plastic products and bring them into a circular economy, he said, ‘we’d decouple ourselves from oil and gas as the carbon source for new production because the carbon source we use would be the plastic waste’.

He said more could also be done with labelling so that customers know whether, for example, a product is compostable and which waste stream it needs to be placed in to achieve that. He also noted that addressing our single-use culture would be a good place to start if we want to change the business model of linear use.

3 - Broaden the discussion and pull those policy levers

The good news is that there is an appetite for change. ‘Ten years or so ago there was no consensus that there was a problem,’ Thompson noted. ‘I would argue that this has changed.’ However, he also feels that it is essential to gather reliable, independent evidence to inform interventions, rather than espousing solutions that could make things worse.

‘We need to gather that evidence from different disciplines,’ he said. ‘We need to have at the table product designers and couple them with the waste managers. We need to have economists at the table. We also need to bring in social scientists to look at behaviour. We’ve got to think about this in the round.’

He also felt that policy measures – such as mandating recycled content – could be a good option, along with better design and disposal.

The tools we need to tackle plastic pollution are already at our disposal. We just need to act more responsibly – which, unfortunately, has been part of the problem all along.

As Professor Thompson said: ‘It’s not the plastics per se that are the problem – it’s the way we’ve chosen to use them.’

>> For more interesting SCI talks like Professor Thompson’s, check out our YouTube channel.

>> Find out more about the work of Professor Thompson and his colleagues here: https://www.plymouth.ac.uk/research/marine-litter.

At COP26, Nikita Patel co-hosted the Next-Gen debate, where an inspiring group of young people discussed how chemistry is tackling climate change. The PhD student at Queen Mary University of London shares her experience.

While the United Nations Climate Change Conference (COP26) may be over, there is still plenty to be done in the fight against climate change. We’ve seen what can be achieved when we work together and no doubt science will play a key role.

On Thursday 4 November, I had the privilege of co-hosting the Countdown to Planet Zero Next-Gen debate organised by SCI to showcase the work being carried out by our young and innovative scientists to tackle climate change. It was a real pleasure to share the stage and hear from some great scientists, exploring the themes Fuels of the Future, Turning Waste into Gold and Engineering Nature. The event gave the audience the opportunity to question and challenge the panel members on their climate change solutions.

Panel L-R: Dominic Smith, Natasha Boulding, Clare Rodseth, Jake Coole, Nikita Patel, Oliver Ring (Brett Parkinson joined virtually).

While I was feeling nervous about my hosting duties, I was very excited at the same time as I knew how important it was to educate the audience, whether they were members of the public or aspiring scientists, on how science is crucial in battling the climate emergency.

An important part of my role as a host was to ensure the incoming questions and comments were understood by all, given the mixed audience attending. This highlighted how essential good science communication is to prevent misunderstandings and the spread of misinformation.

It was brilliant to see how engaged the audience were from the flurry of questions that came in during the session, so much so that we didn’t manage to get through all of them! There were a wide variety of questions aimed at particular panellists but also towards the panel as a whole. It was thought-provoking to hear how scientists from different backgrounds offered their own perspectives on the same topic.

4 November was also Energy Day at COP26 and the atmosphere was buzzing! I learnt a lot from attending the Green Zone, not only from our panellists but from all the exhibitors present too. I appreciate the small, individual actions we can each take that will make a difference but also the need to work together to achieve the common goal of fighting climate change. It was clear to see how science and business go hand in hand to provide solutions to society and how interdisciplinary collaboration is key.

The result of our poll question: ‘Do you think that science is pivotal in providing climate change solutions?’ spoke for itself, with a resounding yes from 100% of the audience participants! This was a very positive outcome and showed that it is not all doom and gloom when it comes to discussing the climate crisis.

On a personal level, I'm going to continue implementing some simple changes like using public transport more, eating more vegan food and flying less and aim to keep the discussion going with my peers as the climate emergency is far from over.

SCI team, panellists and hosts.

I hope the youth panel event has inspired the next generation of scientists and showcased some of the exciting work that is going on behind the scenes which people may not realise and ultimately, that there is hope in science.

>> To rewatch the event, the recording is available on the COP26 YouTube channel: Countdown to Planet Zero Combating climate change with chemistry | #COP26, and on our Climate Change Solutions hub.

>> Want to read more about the technologies discussed by our panel? Read our event review: https://www.soci.org/blog/2021/11/2021-11-05-cop26-review.

A group of inspiring young scientists took centre stage at COP26 on 4 November to show how the next generation of chemists is finding tangible climate change solutions.

In a day dominated by what countries pledged to stop doing at COP26, such as pursuing coal power and financing fossil fuel projects overseas, it was refreshing to learn about low-carbon technologies and the young people driving their development. At the Next Gen forum, we heard from an array of young chemists, all associated with SCI, who are at the sharp edge of this change.

We heard from Brett Parkinson, Senior Engineer of Low Carbon Fuels and Energy Technologist at C-Zero, who is working on commercialising a way to decarbonise natural gas. The California-based company’s technology converts the natural gas into hydrogen and solid carbon to provide a clean energy source while sequestering the carbon; and the aim is to have this process up and running next year.

Natasha Boulding is building towards Net Zero a different way – with a greener concrete. The CEO and Co-founder of Sphera has developed a lightweight carbon negative additive using waste plastics that aren’t currently being recycled. She says the company’s blocks are the same strength and price as existing concrete blocks, but with 30% more thermal insulation. There is also the added benefit of reusing waste materials that would otherwise have gone to landfill or been incinerated.

Another solution discussed by Dominic Smith, Process Development Engineer at GSK, reduces energy consumption through green chemistry. He is trying to find greener ways to make medicines using enzymes. These enzymes, which can be found in plants and soil, replace chemical synthesis steps to cut energy consumption during processing and reduce hazardous waste.

Panel (left to right): Dominic Smith, Natasha Boulding, Clare Rodseth, Jake Coole, Nikita Patel, and Oliver Ring (Brett Parkinson spoke via video link).

It was apparent from the discussion that many solutions will be needed for us to reach our climate change targets. On the one hand, Jake Coole, Senior Chemist in Johnson Matthey’s Fuel Cells team, is working on membrane electrode assembly for hydrogen fuel cells to help us transition to hydrogen-powered buses and trucks.

At the same time, Clare Rodseth, an Environmental Sustainability Scientist at Unilever, has been using lifecycle assessments to reduce the environmental impact of some of the 400 Unilever brands people use all over the world every day. For example, this work has helped the company move away from petrochemical ingredients in its home care products. ‘Even small changes,’ she said, ‘have the potential to bring about large-scale change.’

Incremental change

However, for each of the technologies discussed, barriers remain. For Coole and co., having a readily available supply of hydrogen and charging infrastructure will be key. And for Dominic Smith and his colleagues, the use of enzymes in green chemistry is still in its infancy; and getting enzymes that are fast enough, stable enough, and produce the right yield is difficult. Nevertheless, he noted that manufacturers are now using enzymes to produce the drug amoxicillin, reducing the carbon footprint by about 25%

And some things will take time to change. Natasha Boulding noted that concrete is the second most used material in the world after drinking water, and we simply can’t create many green technologies, such as wind turbines, without concrete foundations.

She said the construction industry is quite traditional but also pointed to perceptible change, with the green concrete market growing and companies becoming increasingly aware of their carbon footprints.

Collaboration was seen as crucial in producing climate change solutions.

The reality is that global action on climate change is recent. As Brett Parkinson said: ‘the main reason we’re talking about it now is that there’s a driver to do it. Until the last decade, the world hadn’t cared about CO2 emissions. They just talked about caring about it.’

How pivotal is science in all of this?

So, what could be done to make climate action more effective? For Parkinson, effective policy is key. He argued that if the market isn’t led by policies that encourage low-carbon innovations, then it won’t work as needed. ‘It all starts with effective decarbonisation policy,’ he said. ‘Legacy industries are very resistant to change. If you don’t have strong and consistent policies… then they’re not going to adapt.’

Another key to our low-carbon evolution is collaboration, and the SCI provides a confluence point for those in industry and academia to work together to produce innovative, low-carbon products. As Clare Rodseth said: ‘Collaboration is really important – linking up people who can actually come together and address these problems.’

As the discussion came to a close, you had the impression that the debate could have gone on for much longer. ‘Hopefully, we’ve demonstrated that there is action, and it’s being driven by young people like our panellists today,’ summarised Oliver Ring, the event’s co-Chair, before asking for the result of the audience poll.

The question: How many of those watching believed that science is pivotal in providing climate change solutions?

The answer: Just the 100%.

>> Thank you to Johnson Matthey for sponsoring the event, to the speakers for sharing their time and expertise, and to co-chairs Nikita Patel and Oliver Ring for doing such an excellent job.

SCI’s America International group has awarded the 2021 Perkin Medal to Dr Jane Frommer. The 114th Perkin Medal was presented to Jane at the Bellevue Hotel in Philadelphia, Pennsylvania, in recognition of her outstanding contribution to chemistry.

Dr Jane Frommer

Dr Frommer is renowned for her key contributions in electronically conducting polymers and scanning probe instrumentation. Her pioneering work with scanning probes paved the way for their use in chemistry, materials science and, eventually, in nanotechnology. According to SCI America, her nanoscopic analytic methods are vital to nanostructural research and are used across many industries.

Dr Frommer began her career in 1980 at Allied Corporate Laboratories (now Honeywell), where she created the solution state of electronically conducting organic polymers. In 1986, she joined IBM where, along with other instrumentalists, she demonstrated the ability to image and manipulate single molecules using scanning tunnelling microscopy. During her multi-year assignment at the University of Basel Physics Institute in the early 1990s, Dr Frommer’s team expanded the capability of scanning probes in measuring the functional properties of organic thin films with atomic force microscopy.

Since 2018, she has worked as a science advisor for Google. In this capacity, she has sought to increase the amount of open source data available in the physical and life sciences. She also helps Silicon Valley start-ups navigate the chemical and material challenges of nanotechnology and has mentored countless students and young scientists in high school, college, and in her laboratory in recent decades.

Previous recipients of the Perkin medal include Barbara Haviland Minor, of the Chemours Company, and Ann E Weber, of Kallyope Inc.

Dr Frommer has written more than 100 referred publications and is the co-inventor of more than 50 issued patents. With her extraordinary body of work spanning more than 40 years, she is a worthy recipient of the prestigious Perkin Medal.

The Perkin Medal is widely acknowledged as the highest honour in American industrial chemistry. It was established to commemorate the 50th anniversary of William Henry Perkin’s discovery of mauveine at the age of just 18. Perkin’s creation of mauveine, the world’s first synthetic aniline dye, revolutionised chemistry and opened up new frontiers in textiles, clothing, and other industries. Perkin was a founding member of SCI and this Medal was first presented to him in New York in 1906.

For more information on the Perkin Medal and the nomination process, visit: soci.org/awards/medals/perkin-medal

The War on Plastic is a grand title. To most of us, it doesn’t seem like much of a war at all – more like a series of skirmishes. Nevertheless, if you look closely, you’ll see that a lot of companies are tackling the issue.

GSK Consumer Healthcare (GSKCH) is one such organisation. The healthcare brand that gave us Sensodyne and Advil has launched a carbon neutral toothbrush to reduce our reliance on fossil fuels (which create virgin plastic).

The composition of its Dr. Best tooth scrubber is interesting. The handle comprises a mixture of a cellulose derived from pine, spruce, and birch trees and tall oil, which comes from the wood pulping industry. The bristles are made from castor oil and the plastic-free packaging includes a cellulose window.

According to GSKCH, Dr. Best is Germany’s favourite toothbrush brand and there are plans to apply the technology to toothbrushes across its portfolio, including its Sensodyne brand. At the moment, GSK needs to apply carbon offsetting initiatives to make the toothbrush carbon neutral, but it says it is working on future solutions that do not require this approach.

Net zero shopping

GSK isn’t the only company that is actively reducing the use of plastics and minimising waste. Supermarket chain Morrisons has made aggressive moves in recent years to cut waste, and has just launched six ‘net zero waste’ stores in Edinburgh that will operate with zero waste by 2025.

Customers at these stores will be able to bring back hard-to-recycle plastics such as food wrappers, foils, yoghurt tubs, mixed material crisp tubes, coffee tubs, batteries, and plant pots. At the same time, all store waste will be collected by a range of specialist waste partners for recycling within the UK, and unsold food will be offered to customers at a cheaper price on the Too Good to Go app.

Morrisons’ proactive approach will help find a new life for hard-to-recycle packaging.

‘We’re not going to reach our ambitious targets through incremental improvements alone,’ said Jamie Winter, Sustainability Procurement Director at Morrisons. ‘Sometimes you need to take giant steps and we believe that waste is one of those areas. We believe that we can, at a stroke, enable these trial stores to move from recycling around 27% of their general waste to over 84% and with a clear line of sight to 100%.

‘We all need to see waste as a resource to be repurposed and reused. The technology, creativity and will exists – it’s a question of harnessing the right process for the right type of waste and executing it well.’

If this approach is successful, Morrisons plans to roll out the zero waste store format in all of its 498 stores across the UK next year.

>> Interested in reading more about sustainability and the environment? Check out our blog archive.

Stamping out single-use plastics

The government has also issued its latest battle cry in the war on plastics. Having defeated plastic straws, stirrers and cotton buds, it has turned its attention to other single-use plastics.

Single-use plastic plates, cutlery and polystyrene cups are among the items that could be banned in England following public consultation.

The humble cotton bud has now been retired from active service.

Somewhat surprisingly, it estimates that each person in England uses 18 single-use plastic plates and 37 single-use plastic items of cutlery each year; so, it has begun moves to cut out this waste stream.

Environment Secretary George Eustice said: “We have made progress to turn the tide on plastic, banning the supply of plastic straws, stirrers and cotton buds, while our carrier bag charge has cut sales by 95% in the main supermarkets. Now we are looking to go a step further as we build back greener.”

All in all, it’s encouraging to see that companies and the government are brushing up on their sustainable practices.

>> Curious to find out what the future looks like for lab-processed food and meat alternatives? Read what the experts say here.

Life is busy for Rhys Archer. Outside of her work as EPSRC Doctoral Prize Fellow in Biomedical Materials at the University of Manchester, she founded Women of Science to share stories about real women working in science. She has championed STEM in schools in her spare time and received the Robert Perrin Medal from the Institute of Materials, Minerals, and Mining – all before her 30th birthday.

Rhys is also refreshingly forthright in her views. She took the time to speak to us about everything from attitudes towards disability in academia, the problem with STEM statistics, and finding that sense of belonging in science.

Would you mind telling me about your work at the University of Manchester and the research areas that interest you most?

My research interests have always been interdisciplinary – I am a bit of a magpie when it comes to research and I get excited by projects in different areas. Luckily, being a researcher in materials science means that I can apply my knowledge and skills in a wide array of areas and industries. I have recently finished my doctoral studies looking at how carbon fibre composites are damaged during impacts, and how to toughen them while keeping composites light weight, which is particularly useful in the aerospace industry. However, I have since moved over to research in biomedical materials, specifically within tissue engineering, where I am researching biocompatible composite scaffolds for tissue regeneration.

You set up Women of Science in 2016 to share stories about real people in science. How has this been?

When I set up Women of Science, I first looked at it as a personal project that could be of use in schools to young people. However, it became apparent fairly quickly that access to relatable role-models in STEM was needed, not just in schools but also for women across the STEM industry.

Since then, we have been fortunate to be awarded funding to grow the work we do and expand our audiences. One of the most important actions I have taken with Women of Science is to set up an advisory board (which includes a diverse range of women) to share ideas and to influence the direction and activities of Women of Science.

As well as the impact on others, Women of Science has had a huge impact on me personally. When I set up Women of Science I was going through a difficult period of feeling isolated, and found it difficult to feel a sense of belonging in science and in research. By reaching out and hearing other women’s stories – not just their achievements, but also their doubts, worries, and difficulties – I found that I did belong in STEM. I just had to search for it.

Would you mind sharing some of the successes and challenges you’ve experienced in your own career?

At 29, towards the end of my PhD, I was diagnosed as autistic. Looking back, I can see that the challenges I faced, particularly because of depression, anxiety, and isolation, were due to my needs not being considered or met. Being disabled in academia is an ongoing challenge. It is still a fight to gain equitable working arrangements, opportunities, and acceptance.

However, I can also see how the successes I have had, such as setting up Women of Science, and being a part of other projects are a result of ‘being different’. My strongest quality is a diversity of perspective and experience and an eagerness to be a part of a range of different projects.

>> We’re keen to hear diverse perspectives from people working in the chemical industry. Get in touch with us at: eoin.redahan@soci.org

You have championed inclusivity in STEM. Do you think academic institutions and other workplaces could be more inclusive?

Yes. I think there is a huge amount of awareness and conversation about inclusivity in academia and industry, but not nearly as much action and intervention. Often I see workplaces with inclusive policies, but with little consideration of monitoring, evaluating, or reconsidering those policies. We must move past equity, diversity, and inclusivity being a checkbox exercise. The issues faced by women in the workplace are intersectional and complex, and so require well considered, complex solutions.

According to WISE, women now make up 24% of the STEM workforce in the UK. It estimates that this number could rise to 29% by 2030. What do you think about these figures?

While the number of women in STEM is a common metric when considering equality, this does not accurately portray issues surrounding inclusion and belonging. How are women treated? Do they have the opportunity to advance? Are there equitable policies and measures in place? This is particularly true of women in STEM who identify with other protected characteristics around race, disability, sexual orientation, and class. Once you dig into the statistics (where available) further, it is clear that the numbers given are not sufficient to describe the current situation for all women in STEM.

Also, the ‘leaky pipeline’ model is often considered, that is, that the number of women in STEM fall as we follow the statistics from school, to university, and onto the workplace. However, what is not always considered is that, as with a leaky pipeline, when more women are added, rather than ‘fixing’ the pipeline, the cracks become more obvious. Eventually, we reach a point when the pipeline is fractured. We must focus on repairing these cracks, not just increasing a numerical metric.

Additionally, in this current climate, it is incredibly difficult to make predictions as to what the future holds for the number of women in the STEM workforce. A couple of years ago, we could not foresee the impact that a global pandemic would have on women. When we consider the possible effects of climate change over the next decade, can we predict the burden that will be placed on women, or how this will affect women’s choices?

What’s next for you? Are you involved in any exciting projects?

With Women of Science, we have three projects that will be launched towards the end of the year, including a new website, flashcard activities for young people, and a report on the impact of the pandemic on women in STEM. Further ahead, I would love to expand the reach of Women of Science further, working with podcasting and film, as well as reaching out to policy makers. Personally, I am excited to get my teeth stuck into a new research project and see where that leads, as well as doing more teaching, consulting, and any other opportunities that come my way!

>> Are you interested in getting involved in Women of Science? Visit: www.womenofsci.com

A little talked about element, with the atomic mass 140, plays a surprisingly important role in everyday life. It has not only lit many a path, but can be credited with improving and saving the lives of billions of people by enabling cleaner air.

In his talk '140Ce: White light & Clean Air' Andy Walker, Johnson Matthey’s Technical Marketing Director explained why the soft, ductile silvery-white metal Cerium, deserves more recognition.

Walker began by outlining the history of SCI, celebrating its 140th anniversary this year. As an employee of Johnson Matthey, Walker highlighted that George Matthey was among the pioneers of SCI. In addition Walker explained that his PhD research had involved looking at catalysts that included Cerium.

Cerium is a lanthanide and the 26th most abundant element on earth. Indeed it was the first lanthanide to be discovered, found as its ore cerium silicate, in 1803. Cerium makes up 66ppm of the earth’s crust, which is about 5 times as much as lead. It is the only one of the lanthanides able to take on the +4 oxidation state, making it very useful in some of its applications. It is mined in the US, Brazil, India, Sri Lanka, Australian and China, with annual global production of 24 000 tonnes.

However, this straightforward look at the history of Cerium conceals a much more interesting narrative about how this element shaped the life of a number of prominent chemists of the day. Indeed Cerium was found as early as 1751 at a mine in Vestmanland, Sweden by Axel Cronstedt, who also discovered Nickel. Believing it to be an ore of Tungsten, he sent it to Carl Wilhelm Scheele for analysis. However, Scheele was not able to identify it as a new element.

This turn of events for Scheele, perhaps unfairly, helped to seal his moniker as the ‘unlucky chemist’. Scheele, a prominent chemist and pharmacist, had a number of discoveries to his name. He isolated lactic acid, and discovered hydrogen fluoride and hydrogen sulphide.

But as Walker explained, his most notable discovery was oxygen, some three years before Joseph Priestley. Sadly for Scheele; it took him six years to publish his findings, by which time Priestley had already presented his data. Putting a contemporary slant on Scheele’s misfortune, Walker added that the cautionary tale here was that getting things out into the public domain as soon as possible can be important to ensure credit goes to the right people.

Further work by Scheele led to the discovery of a number of elements including barium and chlorine, but sadly he did not receive any recognition because he didn’t manage to isolate them and identify them correctly. The chemist Sir Humphrey Davy did so, some years later, getting the credit for their discovery and isolation.

So it was in 1803 that chemists Wilhelm Hisinger and Jons Jacob Bezelius proved that Cerium was indeed a new element, naming it Cerium after an asteroid/dwarf planet which had been called Ceres. The successful isolation of Cerium took place in 1875, carried out by American chemists William Hillebrand and Thomas Norton, by passing an electric current through molten cerium chloride.

99.95% fine cerium isolated on white background

Once isolated, the earliest application of Cerium was in incandescent gas mantles. Developed by Carl Auer von Welsbach, in 1891, he perfected a mixture of 99% thorium oxide and 1% ceria, which gave a soft white light. Introducing his new mantle commercially in 1892, von Welsbach was able to monetise his development selling his product throughout Europe.

Gas mantles have been replaced, but Cerium’s importance in producing white light remains. As Walker explained, most white LEDs use a blue gallium nitride LED covered by a yellowish phosphor coating made of cerium-doped Yttrium Aluminium Garnet crystals.

In the medical arena, Cerium was used by Sir James Young Simpson, Professor of Medicine and Midwifery at Edinburgh who did a lot of work in the area of anaesthetics. Simpson found that cerium nitrate suppressed vomiting, particularly that associated with morning sickness, and well into the last century, medication containing Cerium could be bought over the counter. In addition Cerium has been the basis of treatments for burns.

Other applications for this versatile element are self cleaning ovens and mischmetal alloy, used in flints for cigarette lighters. Walker shared that the chemist and author Primo Levi, while imprisoned in Auschwitz, was able to steal cerium-iron rods from the laboratory he was forced to work in. Making them into cigarette lighter flints, he was able to barter for bread. Cerium is used to harden surfaces; it is a good polishing agent. Cerium sulphide has been used to replace the pigment cadmium red as a non-toxic alternative and Cerium is widely used across the chemical industry as a catalyst to produce a host of chemicals.

Catalysis is probably where Cerium has impacted most people as the element is the basis for the catalytic converters that have provided cleaner air for billions of people. Walker explained that the driver for the development came during the 1950s when photochemical smog was a problem in the Los Angeles Basin. Measurements at the time indicated that vehicles were responsible for the majority of the hydrocarbon and NOx emissions that led to the polluted air.

This turn of events led researchers to develop systems that could mitigate the emissions. Johnson Matthey was among those doing the early work on catalytic converters. Meanwhile, the automotive industry was pushing back on their introduction, concerned about the costs, durability and effectiveness. Working with Ricardo Engineering, Johnson Matthey carried out durability tests over 25 000 miles which also showed that the catalysts could pass US emissions tests.

The catalysts had to operate in three ways, at the same time, oxidising carbon monoxide (CO) and hydrocarbons (HC) while reducing NOx. Early catalysts, circa 1975, were based on Palladium and Platinum and focused on oxidising the CO and HC. Around 1978 a second catalyst was introduced to reduce NOx.

However, the introduction of Cerium then made it possible to develop a single catalyst that was able to carry out the functions that the researchers had wanted to achieve. Hence, 1981 saw the introduction of the three way catalytic converter with all three reactions enabled over a single catalyst. More recently ceria-zirconia oxide based catalysts have been developed with much higher oxygen storage capacity than ceria.

The impact of these developments has allowed the implementation of much more stringent air quality and emissions standards. Indeed Johnson Matthey estimates that its Cerium-based catalysts are responsible for removing around 40 tonnes of pollutants every minute of every day.

A single element has indeed impacted many lives.

We always hear about athletes eking out that competitive edge through subtle changes in diet or equipment. Well, when it comes to making our buildings more energy-efficient, dozens of different technologies could make a difference. Every one may not be earth juddering on its own, but each could help decarbonise our homes by degrees.

Phase-changing materials (PCMs) may have a role to play in reducing our reliance on power-hungry cooling and heating systems in the home. At Texas A&M University, researchers have developed PCMs to passively regulate temperatures inside buildings.

They believe their 3D-printed phase-change materials - compounds that can change from a solid to liquid when absorbing heat, or from liquid to solid when releasing heat - could be incorporated into our homes in paint or other interior effects to regulate interior temperatures.

New phase-change material composites can regulate ambient temperatures inside buildings | Image credit: Texas A&M University College of Engineering

Their partial substitute to the heating, ventilation and air conditioning (HVAC) systems that predominate in many of our buildings is a light-sensitive liquid resin with a phase-changing paraffin wax powder.

According to the researchers, their 3D printable ink composite improves upon existing PCMs in that it doesn’t require a separate shell around each PCM particle. When the PCM is mixed with liquid resin, the resin acts as both the shell and building material, enabling thermal energy management without any leakage. They use an ultraviolet light to solidify their 3D printable paste and make it suitable for use in our buildings.

“The ability to integrate phase-change materials into building materials using a scalable method opens opportunities to produce more passive temperature regulation in both new builds and already existing structures,” said Dr. Emily Pentzer, associate professor in the Department of Materials Science and Engineering and the Department of Chemistry.

To date, the researchers have only tested their materials on a small scale in a house-shaped model. Nevertheless, after placing their 3D printed model inside an oven, the results were encouraging. The model’s temperature was 40% different to outside temperatures compared to models made using traditional materials.

From solar panels and insulation to heat pumps and phase change materials, much has been done to make our homes more energy-efficient

“We’re excited about the potential of our material to keep buildings comfortable while reducing energy consumption,” said Dr. Peiran Wei, research scientist in the Department of Materials Science and Engineering and the Soft Matter Facility. “We can combine multiple PCMs with different melting temperatures and precisely distribute them into various areas of a single printed object to function throughout all four seasons and across the globe.”

Perhaps we won’t see PCMs in widespread use in our buildings any time soon, but it’s always heartening to see the use of passive heating and cooling systems in our buildings. Anything that contributes to the decarbonisation mix is certainly worth investigating further.

Which technologies will propel industry forward and give companies that competitive advantage? According to digital consultancy McKinsey Digital’s Tech Trends Index, several technologies will have a profound and disruptive impact on industries including the chemical sector. So, which ones will have the biggest effect on the way you work in the coming decade?

1: Automation

By 2025, more than 50 billion devices around the world will be connected to the Industrial Internet of Things (IIOT) and about 600,000 industrial robots a year will be in place from 2022. The combination of these, along with industrial processes such as 3D and 4D printing, will speed up processing and improve operational efficiency.

According to McKinsey, 50% of today’s work practices could be automated by 2022 as ever more intelligent robots (in physical and software form) increase production and reduce lead times. So, how does this change look in the real world?

According to the McKinsey Tech Trends Index, 10% of today’s manufacturing processes will be replaced by additive manufacturing by 2030.

According to the Tech Trends Index, one large manufacturer has used collaborative robots mounted on automatic guided vehicles to load pallets without human involvement, while an automotive manufacturer has used IIOT to connect 122 factories and 500 warehouses around the world to optimise manufacturing and logistics, consolidate real-time data, and boost machine learning throughput.

2: Next generation computing

An almost incredible 368,000 patents were granted in next generation computing in 2020. Advanced computing will speed up the processing of reams of data to optimise research and cut development times for those in the chemicals and pharmaceuticals industries, accelerate the use of autonomous vehicles, and reduce the barriers to industry for many eager entrants.

‘Next-generation computing enables further democratisation of AI-driven services, radically fast development cycles, and lower barriers of entry across industries,’ the index notes. ‘It promises to disrupt parts of the value chain and reshape the skills needed (such as automated trading replacing traders and chemical simulations, reducing the need for experiments).’

According to McKinsey, AI will also be applied to molecule-level simulation to reduce the empirical expertise and testing needed. This could disrupt the materials, chemicals, and pharmaceuticals industries and lead to highly personalised products, especially in medicine.

3: The Bio-revolution

It doesn’t take much investigation before you realise that the bio-revolution has already begun. Targeted drug delivery and smart watches that analyse your sweat are just two ways we’re seeing significant change.

The Tech Trends Index claims the confluence of biological science and the rapid development of AI and automation are giving rise to a revolution that will lead to significant change in agriculture, health, energy and other industries.