21 Sept 2010

Every year, the Seligman APV Trust invites recent graduates and postgraduates or equivalent to study in one or more of the UK’s renowned centres of food engineering teaching and research.

From 2009-10, Dr Pramod Rai used his visit to the UK to investigate the respiration behaviour of mixed salad and the role of relative humidity in modified atmosphere packaging of fresh cut fruit and vegetables

Research project

Project objectives

- Determination of respiration rate of cut salad (white cabbage, curly lettuce and spinach) and cauliflower florets

- Determination of temperature and relative humidity inside the packed salad and cauliflower florets

- Selection of packaging film for modified atmosphere packaging (MAP) of fresh/cut produce based on modified atmosphere (MA) and modified humidity (MH)

Novel aspect(s) of research

The respiration rate plays a vital role in selection of packaging film for fresh/cut fruit and vegetables. Respiration rate of individual and mixed salad was determined, to find out their behaviour in mixed salad. Currently the selection of packaging film during MAP of fresh/cut produce is based on optimum gas requirement (O2 and CO2). There is a need to understand the behaviour of relative humidity during MAP and selection of film based on modified atmosphere (MA) and modified humidity (MH).

Key findings

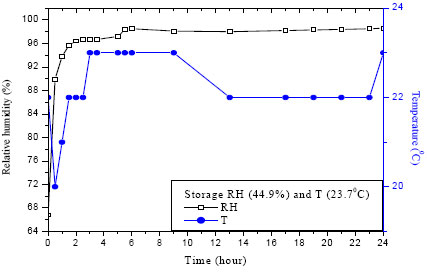

The respiration rate of cut salad of white cabbage, curly lettuce and spinach behave in a synergistic way and overall respiration rate is lower than individual components. The typical behaviour of temperature and relative humidity in packed cauliflower florets is shown in the figure given below.

Future Research Work

There is a need to undertake a thorough study of respiration behaviour for mixed salad and the role of relative humidity during MAP of fresh/cut fruit and vegetables.

Visits and Training

Visits

- Dr Joe Quarini, Department of Mechanical Engineering, University of Bristol

The discussion during my visit was focused on ice pigging, heat transfer in cereal baking and utilisation of waste heat from food factories, as well as innovation in research. - Dr I A Wilson, Department of Chemical Engineering and Biotechnology, University of Cambridge

The discussion was focused on the formation and processing behaviour of structured semi-solid materials, fouling and cleaning mechanisms in food industry. The role of fluid dynamic gauging (FDG) in measurement of fouling layer thickness was also discussed. - Dr Leon Terry, Food Security and Environmental Health, University of Cranfield

The broad area of discussion was fresh produce supply chain system. The more specific discussion was done development of new Palladium-based ethylene scrubber, optimising storage potential mango cultivars using chemometric analysis and MAP of lychee. - Dr Andrew Livingston, Department of Chemical Engineering and Chemical Technology, Imperial College, London

The discussion focused in the area of Separation Engineering and Technology especially organic solvent nanofiltration, technology for peptide and oligonucleotide production, and high-value natural products - extraction and purification. - Dr Alan Campbell, Dr Craig Leadley, Dr Lynneric Potter and Dr Gary Tucker, Campden BRI, Chipping Campden, Gloucestershire

The visit gave me detailed exposure of packaging equipment, food processing pilot plants, bakery and novel non-thermal processing technology. - Dr Paul Skudder (APV), SPX Flow Technology

I learned about the work of SPX Flow Technology and APV in their new setup. Discussions here focused their expertise in membrane technology and its application to the dairy industry. - Mr D J Humphries, The Centre for Dairy Research, University of Reading

I was introduced to the overall operations of the Centre for Dairy Research and learned such research issues as feeding and metabolism, manipulation of proteins, and the fat ratio in milk. - Society of Chemical Industry, London

Ms Monica Ugalde explained SCI's activities, took me on a tour of its premises and introduced me to staff.

Training

- Attended one-day workshop on 'Creating and managing a sustainable food supply chain - meeting the challenge' at Campden BRI, UK.

- Attended one-day training programme on 'HACCP- the basics' at Campden BRI, UK

- Laboratory Safety Training, Health and Safety Services, University of Reading, UK

- Attended series of lectures (SEM, ESEM and Cryo-SEM, X-ray Analysis in the SEM and Infra-red/Raman Microscopy, Scanning Probe Microscopy) at Centre for Advanced Microscopy, J J Thomson Physical Laboratory, University of Reading, UK.

About Pramod Rai

Academic/Professional Awards

- Selected for Young Engineer Award 2009 by Institution of Engineer (India), Kolkata.

- Awarded APV Seligman Fellowship Award 2009 by SCI.

- The National Agricultural Innovation Project, ICAR, India nominated me for three months advance training in the area of Non-chemical/Non-thermal Processing and Membrane Technology at Washington State University, US.

- Awarded the best paper presentation for the paper entitled Ultrafiltration of Tender Coconut Water for Packaging in the oral session Novel Separation Processes-II during SCHEMCON 2005, IIT Guwahati.

- Selected for Young Student Speakers' Event during IFCON-2003, CFTRI, Mysore. Top of group during my B.Tech and awarded Merit Scholarship by Rajendra Agricultural University in recognition of excellent results during last six successive semesters.

Publication/Patent

Published more than 25 publications in various referred international and Indian journals and contributed three book chapters. One patent is filed.

Research interests

- Application of membrane technology in liquid food processing,

- Fresh/cut produce supply chain management

- Extraction of photochemical, nutraceutical using novel techniques

Fellowship period and location

I spent my Fellowship with Dr Keshavan Niranjan, Department of Food and Nutritional Sciences, University of Reading, from 4 November 2009 to 25 February 2010.

Achievements and benefits

Achievements

- Awarded the foundation certificate in HACCP by Royal Society of Public Health, UK.

- K Niranjan, Pramod Rai and Prakash Korde (2010). Processing technologies for valorizing agricultural produce – the need for synergism between food and agricultural sciences. International Conference on Post-Harvest Management and Valorization of Agri-Horticultural Produce and Exhibition, 19-20 February 2010, NASC Complex, New Delhi.

- Invited to contribute a book chapter on chemical aspects of pulses in the book Pulse Foods: Processing, Quality and Nutraceutical Applications, edited by Brijesh Tiwari, Aoife Gowen, and Brian McKenna to be published by Elsevier.

- Invited to review the research paper of Journal of Food Engineering and Food Chemistry. Wiley invited to review the book proposal Handbook of Phytochemicals: Sources, Processing and Applications edited by Brijesh Tiwari and Nigel Brunton.

- Research paper under preparation on the work done at Department of Food and Nutritional Sciences, University of Reading.

Benefits

- I benefited from the opportunity to work with Dr K Niranjan, a stalwart of Food Engineering. The research work done during my fellowship in the area of respiration behaviour of mixed salad and role of relative humidity during MAP of fresh/cut fruit and vegetables, opened an innovative and challenging area of research for me.

- The Fellowship gave me the opportunity to visit different universities and companies and helped me learn about various emerging researchable issues in Food Engineering. I welcomed the opportunity to interact with eminent scientists working in my area of interest.

- Attended training in food supply chain management, food safety and application of advanced microscopy in food science and technology. The training provided the opportunity to learn about area of research and concern in the food chain system.

- Finally, the visit gave me the opportunity to interact with many people in the UK, which helped me better understand the country's social fabric and the aspirations of its people.

Acknowledgements

I would like to thank the Seligman APV Trust, set up in honour of Richard Seligman, its management committee, and SCI for selecting me for this prestigious fellowship.

Special thanks go to Mr Graham Byars, Chairman, Seligman APV Trust and Ms Monica Ugalde, Membership Services Manager, for their comprehensive care and personal attention.

I am grateful to Prof Keshavan Niranjan, University of Reading, who has supported and guided me during research and making my stay a memorable one. I express thanks to all those who have given me their time and the opportunity to learn during my visits to universities and companies.

I am also grateful to my employer, Birsa Agricultural University, Ranchi, Jharkhand, India for allowing me to take up this fellowship.

Finally, but not least, to my family for their support and encouragement.

I am very grateful to the Almighty for his enlightenment and strength throughout my life.