26 Sep 2013

Every year the Seligman APV Trust gives non-UK resident graduates or postgraduates or equivalents with a food engineering background the opportunity to apply for a Seligman APV Award and study at the UK's renowned research centres. The award is named after its founder, Dr Richard Seligman.

I am very grateful to the SCI Seligman APV Committee for giving me the opportunity to take up this award and to further my research project. I'm the second Italian since 1993 and very proud to have received this award.

My living and working experience in the UK began on 4 January and ended on 5 July 2013. For six months I was a PhD Student at the University of Reading, under the supervision of Dr Paula Jauregi and Professor Keshavan Niranjan. I worked in the Food Bioscience Department (FaBS) and performed my project on Colloidal Gas Aphron application on food by-products. During this period I made one visit and took part at different seminaries and conferences.

Visits

Unfortunately, many companies' internal regulations are very restrictive for external visitors and it is very difficult get authorisation. For this reason I could do only make one visit. With Mr Paul Skudder, Chief Technologist at SPX Flow Technology in the UK, I went to Denmark for three days to visit the SPX Innovation Centre. Here I learned about the main problem in the dairy industry, which involved membrane technology and an innovative cleaning system based on the reuse of caustic soda.

SCI gave me the change to meet many experts in my field at its 'Waste Not Want Not: Agri-Food Waste Solutions for a Hungry World' conference on 5 March 2013. I presented a poster and my paper was published in Chemistry & Industry, April 2013.

Thanks to Mr Graham Byars, I gave a talk at SCI's 2013 AGM on my project, and I met many experts in the food engineering field.

Research project and project objectives

Wine production is one of the most important agricultural activities in the world with 7,528,000 hectares of vines under cultivation. World wine production was around 252 million of hectolitres (Mhl) in 2012. Europe is the main producer and the most important countries are Italy and France, with a total production of 40 Mhl, followed by Spain with 30 Mhl in 2012. The yield in wine from grapes used is around 65-70%. This means that the wine-making process produces more than 30% of by-products as stalks, seeds and grape skin.

These wine-making by-products are rich in different bioactive compounds, for example grape stalks are a source of dietary fibres that promote beneficial effects on human health as reduction in low-density cholesterol and sugar absorption.

Grape seeds contain linoleic acid, which is one of the most important omega six series fatty acids, and is able to reduce LDL cholesterol adsorption. A larger amount of by-products is represented by grape marc, a mixture of skins and seeds which are rich in polyphenols. Grape polyphenols are monomeric and polymeric molecules, and he ones located in the skin are anthocyanins, flavan-3-ols, flavonols, dihydro-flavonols, hydroxybenzoic acids and hydroxystilbenes.

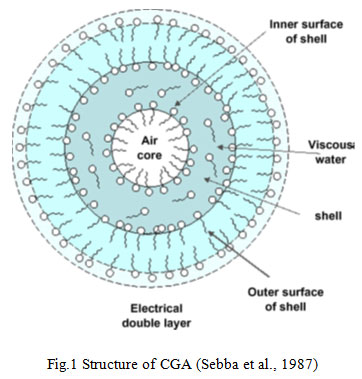

Colloidal gas aphron CGAs are defined as micro bubbles, with sizes from 10-100 μm created by the intense stirring of a surfactant solution above its critical micellar concentration (CMC). CGAs are composed of a gaseous inner core, surrounded by a multilayer surfactant structure (Figure 1); and they present different dispersion characteristics compared to conventional foams.

The inner surface has oriented surfactant molecules that are hydrophilic pointing inward, and hydrophobic outward. The outer surface has surfactant molecules that are hydrophobic outward. The hydrophobic outer surface absorbs surfactant ions from bulk water to form a diffuse electrical double layer. The removal of suspended particles in a solution can occur in two different ways. One mechanism is by 'bubble-entrained flotation' in which relatively large particles are floated up by the buoyant action of many small bubbles. The second mechanism is called 'ion flotation': charged species form a ion surfactant complex floated up to the electrical double layer.

CGAs have been used for many separation processes such as protein recovery, removal of dyes from wastewaters, and recently also phenolic compounds.

The project objectives are:

- To develop a low cost and environmentally-friendly process to recover phenolic compounds from a food by-product such as waste grape skins

- To investigate the CGA behaviour during the developed process, and the effect of surfactant concentration on CGA's stability

- To investigate the applicability of phenols extract in food and its release during the food shelf life

CGA process

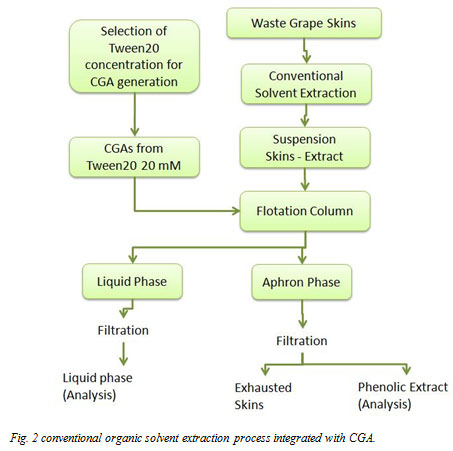

Starting from a previously developed conventional solvent extraction process, CGAs application was integrated into such a process (Figure 2) to increase the yield of the process, the phenolic extract purity and at the same time, to reduce the process costs. The conventional process starts from dried and milled red grape skin mixed with an ethanolic solution (60/40 - v/v Ethanol/Water) for 2 hours at 60°C. The CGAs were applied at the end of the extraction process to recover and purify phenolic compounds from other substances and eventually further extract them from the skins.

The ethanolic suspension (grape skins and ethanol extract) was pumped into a flotation column (a glass column with an internal diameter of 4 cm and height of 56 cm) and afterwards the CGAs were pumped into the column. After a certain contact time two phases separate inside the column: a liquid phase (with solids) at the bottom and one aphron phase on the top.

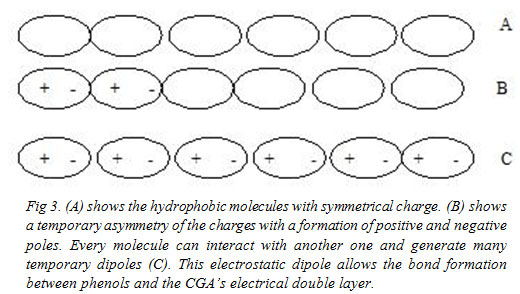

The objective was to separate and concentrate the phenolic compounds in the aphron phase. The separation process is based on the occurrence of hydrophobic and/or electrostatic interactions between phenols and CGA. Polyphenols are mainly non- polar compounds, not completely soluble in water and they can generate hydrophobic interactions with other compounds to minimise the contact with water, while the electrostatic forces are called van der Waals forces.

Usually the non-polar molecules have not permanent dipoles but is possible, thanks to particles movement, the formation of instantaneous dipole-induced dipole forces (Figure 3) thanks to which phenols are able to link to the external bubbles surface composed of an electrical double layer. In such a process, the stability of CGAs is a very important parameter to achieve the maximum phenols recovery, since foam collapse prevents bond formation between phenols and CGA. Since the final application of the phenolic extract wants to be in the food sector, a food grade surfactant has been used: the non - ionic Tween20.

Key Findings

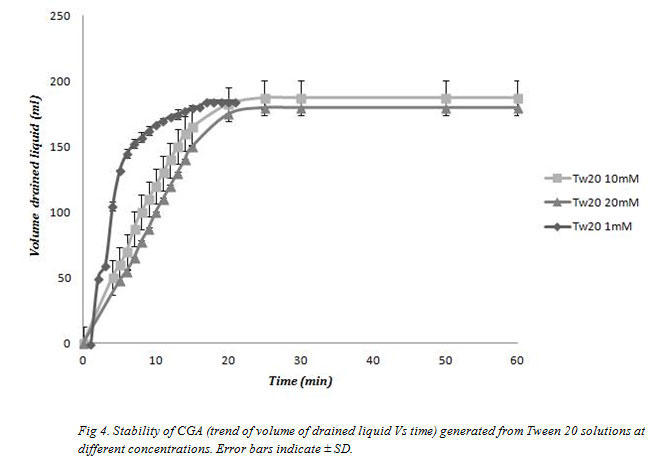

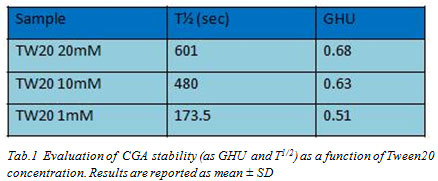

The stability of the foam is one of the main parameters influencing CGAs based process, therefore initial part of the activity was dedicated to stability studies. CGAs were generated from solutions at different surfactant concentrations and the liquid drainage over time was measured

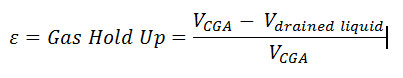

In general, to generate stable CGA it is necessary to exceed the surfactant CMC. The Tween20 CMC is 0.0987 g/L (0.080 mM). The stability can be evaluated in terms of half - life time (T1/2), which is the time required to obtain the half of the initial volume of CGA, and also of Gas hold up (GHU), defined as the amount of air incorporated into the dispersion.

The lower stability (faster drainage and lower T1/2) was observed for Tween20 1mM - CGAs, while Tween20 20mM and 10mM - CGAs showed comparable behaviours with a higher stability for Tween20 20mM, which was then selected for the following experiments. In Table 1 GHU and T1/2 values are reported.

Influence of CGAs pumping flow rate in the CGAs process on CGAs stability and on phenols recovery was investigated. The micro foam stability increase if the flow rate increases but on the other hand the phenols recovery decreases due to the corresponding shorter contact time.

Future Research Work

- Optimise the method to improve the yield in phenols

- Develop a different method to reduce the ethanol amount during the extraction step

- Spray-drying trials: evaluate the influence of surfactant presence and CGAs application on powder properties (mainly solubility in different food matrixes)

Achievements and Benefits

The Fellowship gave me the opportunity to develop my project at the University of Reading, one of the most important research centres in the UK. At the same time, it was a great opportunity to interact with scientists, PhD students, and PostDocs with different backgrounds and expertise in food engineering. This experience allowed me to create a working network outside my native country and also increase my knowledge, mainly in food engineering.

I worked under the supervision of one of the main experts in CGAs application, Dr Paula Jauregi. She helped me to understand better the critical points of this innovative process and develop it in the right way. Moreover she gave me the knowledge to resolve the main problems related to the CGAs application which was specifically investigated.

This award was not only a working experience but it also a great living experience. In this six months I have met many people from different European and non-European countries with different cultures. I've benefited as a person as a result.

Acknowledgements

My thanks to the SCI Seligman APV Trust and its management committee for selecting me for this prestigious fellowship.

I would like to thank Dr Paula Jauregi, Professor Keshavan Niranjan and the University of Reading for their support from the beginning to the last day of this great experience.

I'm very grateful to Mr Graham Byars, Chairman, Seligman APV Trust and Miss Karen Hobbs, Membership Manager at SCI, for having done an excellent work in the Fellowship organisation, for their personal attention and for introducing me at SCI.

I would like to thank my Italian supervisor, Dr Giorgia Spigno, for her constant support during the six months and for persuading me to apply at the Seligman Fellowship selection.

Thanks from the bottom of my heart to my big family for being a family, every day, until the end. The last but not the least, I want to express my heartfelt gratitude to the new 'family' that I found in Reading.

About Matteo Bosi

I was born in the city of Cremona and grow up in a small village called Castelvetro Piacentino, Piacenza, Italy. I attended the Università Cattolica del Sacro Cuore of Piacenza from 2006 to 2009 to earn a Bachelor Degree in Food Science and Technology. My bachelor thesis was on 'Organic Pasta: a case study in the city of Cremona'. It focused on organic pasta from farm to fork in collaboration with Iris Soc. Coop. Agricola a.r.l. a small company in Cremona.

From 2009 - 2011, I attended the Università Cattolica del Sacro Cuore of Piacenza to obtain a Master's Degree in Food Science and Technology. My master's thesis was 'Grana Padano cheese: effect on human blood pressure' and it was developed in collaboration with Guglielmo da Saliceto Hospital in Piacenza under the supervision of Dr Giuseppe Crippa.

Since November 2011, I have been a PhD Student at the Agrisystem Doctoral School developing my project at the Oenology and Food Engineering Institute. My doctoral project is focused on the design and development of innovative methods to recover bioactive compounds from different food by-products.

In 2010 I worked for a project in collaboration with Kraft Food Italia, and during this period I learned different analytical techniques and increased my knowledge in the food processing field.

Matteo Bosi

Institute of Oenology and Food Engineering

Università Cattolica del Sacro Cuore, Piacenza