Batteries are a critical enabler for reaching net zero. As their importance increases, so does the need to better understand how they operate.

Mel Loveridge, Associate Professor (Reader) at Warwick University, gives an overview of the complexities of battery science and how she is working to bring increased understanding to a wider audience.

As the role of batteries has an increasing presence in everyday life, there is now a focus on battery forensic science and advanced characterisation methods – a critical part of understanding the life of a battery, its safety aspects and its cycle life or lifespan.

This forensic analysis and advanced characterisation is the core part the work carried out by Associate Professor (Reader) Mel Loveridge at Warwick University, who says: ‘The aim is to firstly understand and identify early-stage signatures of battery degradation, and ultimately to unearth the root causes and propagation of failure in lithium-ion battery (LIB) components.’

Since LIBs were commercialised in 1991, the electronic devices that use LIBs have diverged considerably, with much larger format batteries now required to electrify transport. This is a critical enabler that is needed if the world is to reach net zero.

‘Much research is focused on developing materials with higher energy and power density to effectively do this, and this is why battery safety considerations are more paramount now than ever,’ says Loveridge.

‘It is only by understanding how materials (electrodes and electrolyte) degrade using sophisticated forensic techniques, that we can feedback into the design of better, safer, more robust and stable components that will last longer,’ she adds.

This is key for the continued range and power improvements in electric vehicles, where ultimately everyday users will benefit from advances in battery materials and manufacturing processes.

Developing characterisation capabilities

This understanding requires effective characterisation capabilities to look at the chemical and structural dynamics that occur inside the battery as it ages. This can be accomplished destructively by autopsy when the battery has reached the end of its life (ex-situ) or done in real time whilst the battery is going through charge-discharge cycling (operando).

Because of the small size of the lithium atom, specialised X-ray based microscopy and other techniques are required to detect and map it. Fully understanding the complex journey of the lithium ions during battery operation is still challenging for the battery community.

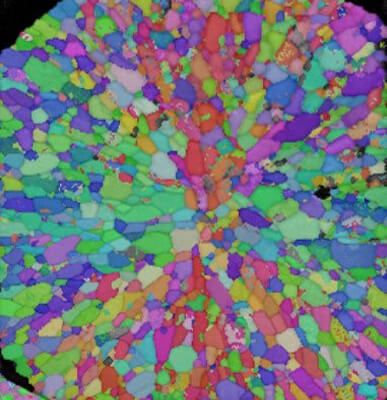

Pictured above: A cathode particle. Copyright WMG

To facilitate this greater understanding, WMG was recently awarded an equipment grant to build the UK’s first multi-modal microscope platform with a plasma focused ion beam sectioning device (deliberately designed with batteries in mind, unlike other systems in existence). This includes a time-of-flight mass spectrometer to enable 3D detection and mapping of lithium. The integrated analytical platform will allow us to understand micro to meso scale structure and chemical dynamics over broad length and time scales.

The recent EU 2030 roadmap (Battery 2030+) stated “The accelerated discovery of stabilised battery materials requires special attention to the complex reactions taking place at the many interfaces within them.” Also awarded was a Lord Bhattacharyya PhD project to work on the commissioning and further development of this characterisation platform.

Breaking down the complexity for government and media

The work is highly challenging and riddled with complexities, but it has attracted significant media and government interest in the last decade and Loveridge has been one of the voices providing accessible, expert insight on a range of media platforms.

‘I have been fortunate to be interviewed for BBC2, Channel 4 and BBC Radio 4, describing how batteries work. I have also participated in energy-related panel discussions with the House of Lord’s Science & Technology Committee and the House of Commons Shadow Cabinet. Prior to this, an article I published on the temperature implications of wireless charging for a mobile phone battery was summarised in a feature in The Telegraph.’

The important work being carried out in battery forensic analysis is set to shape the future of battery technology.