From luminescent polymer nanoparticles that improve rural healthcare to compostable plastic packaging, Dr Zachary Hudson and his research group at the University of British Columbia are developing solutions to pressing issues.

For those of us who live in cities, we take easy access to hospitals for granted, but what about those in remote areas? What if there were an easier way to diagnose diseases and improve healthcare for those in secluded rural areas?

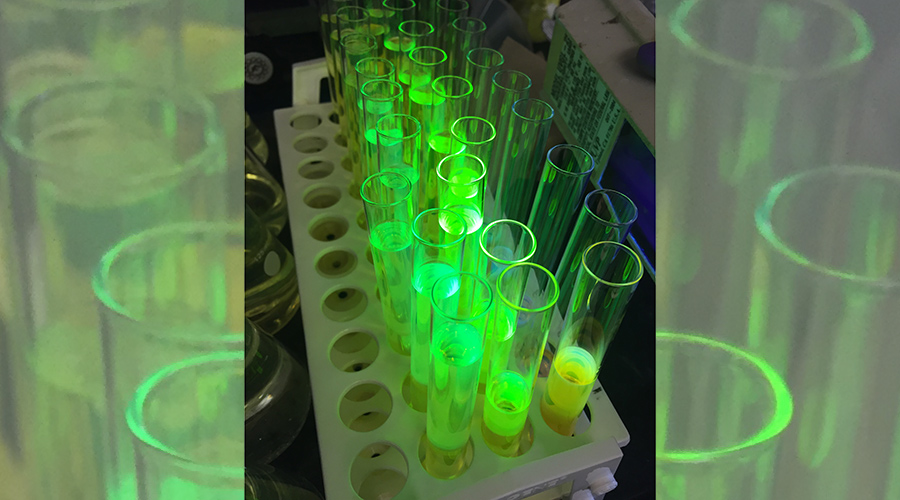

Luminescent dyes used to make fluorescent Pdots.

Well, Dr Zachary Hudson and his group at the University of British Columbia (UBC) in Canada are developing luminescent polymer nanoparticles that could provide portable, low-cost tools for bio-imaging and analysis in rural areas. These nanoparticles are so bright that they can be detected by smartphone, helping clinicians quantify chemical substances of interest such as cancer cells.

Dr Hudson’s work spans other areas too, including working with industry to develop compostable plastics and ongoing research in opto-electronics. His creativity in applied polymer science was recognised recently with the 8th Polymer International-IUPAC award, organised by SCI, the Editorial Board of Polymer International, and IUPAC (International Union of Pure and Applied Chemistry).

We caught up with Zac to ask about these luminous Pdots, compostable plastics, and how it felt to be recognised by his peers.

Dr Zachary Hudson

Tell us about the nanoparticle and remote diagnostic technologies you are developing to boost rural healthcare.

Our group is working with Professor Russ Algar, an analytical chemist at UBC, to develop fluorescent nanoparticles that are bright enough to be detected by a handheld smartphone camera.

The concept is to design nanoparticles that can quantify biological analytes of interest, such as cancer cells or enzymes, and provide a signal that a smartphone can measure. In this way, we hope to create portable, low-cost tools for bioanalysis for use in remote or low-income regions.

Why is the capacity to conduct remote diagnostics so important for those in remote areas?

Coming from Vancouver, I have ready access to sophisticated lab facilities and hospitals that are only a short distance from where I live. This gives me access to some of the world’s most advanced techniques in molecular medicine with relative ease.

For most of the world’s population, however, geography or resources limit their access to these advanced tools that can have a real, positive impact on human health. Expanding access to molecular diagnostic technologies can help more people get the diagnosis they need without a dedicated lab.

How did the ideas for the Pdots come about?

We became interested in Pdots due to Professor Algar’s groundbreaking work using quantum dots for smartphone-based bioanalysis. We learned that by tapping into the versatility of polymer chemistry, we could create polymer nanoparticles, or Pdots, that combined many advanced functions into a single particle.

>> From Covid-19 to the two World Wars, how has adversity shaped innovation? We took a closer look.

How have you worked with other partners to turn these ideas into a reality?

We are currently planning a major initiative with rural health organisations in British Columbia to help move these tools toward practical use. Stay tuned for more info!

You’ve also worked with local industry to reduce the use of single-use plastics. How have you gone about this?

There has been a major push in Canada to reduce the consumption of single-use plastics, and many companies are currently developing new products to respond to this need. Our lab has worked with local industry to formulate and test compostable plastics that can act as substitutes for petroleum-based plastics in consumer packaging.

The Nexe Pod, a fully compostable, plant-based coffee pod created by NEXE Innovations, with Zac as Chief Scientific Officer, received a $1m funding grant from the Canadian government in 2021.

You’ve helped develop compostable materials. How tricky is this from both a material and an environmental perspective?

Compostable plastics are challenging for a few reasons: the demand for them is skyrocketing, so robust supply chains are needed to help companies get away from petroleum feedstocks. The regulatory framework around compostable plastics also varies widely by country, which poses challenges for international commercialisation.

Finally, most machinery for the high-speed manufacturing of plastic packaging is highly optimised for petroleum-based plastics, so new equipment and techniques that are suitable for processing compostable plastics need to be developed alongside the plastics themselves.

>> Do you work in pharmaceutical development? Check out our upcoming events.

What’s next for these innovations, and are you working on anything else interesting?

I've spent most of my career working on light-emitting materials for display technologies and bioimaging, and we’ve recently learned that many of these same materials make useful photocatalysts with applications in the pharmaceutical industry.

We recently partnered with Bristol Myers Squibb to develop all-organic photocatalysts with performance on par with some of the expensive iridium-based catalysts that industry is currently using. I'm looking forward to developing this area further.

What was it like to win the 8th Polymer International-IUPAC award for Creativity in Applied Polymer Science?

It was a great feeling to have our group’s work recognised by the international polymer community. The award lecture at the IUPAC conference also gave us the perfect venue to highlight some of the research directions I’m most excited about in the years ahead.