Every tin can dropped into our recycling bins is a small act of faith. We hope each one is recycled, yet the figures take some of that fervour from our faith. According to UK government statistics from 2015-2018, only about 45% of our household waste is recycled. Similarly, the UN has noted that only 20% of the 50 million tonnes of electronics waste produced globally each year is formally recycled. So, it’s fair to say we could do better.

Thankfully, thousands of people around the globe are working on these problems and two recent developments give us grounds for optimism. The first involves upcycling metal waste into multi-purpose aerogels, and the second involves fully recyclable printed electronics that include a wood-derived ink.

Upcycling metal waste

Researchers at the National University of Singapore (NUS) claim to have turned one person’s trash into treasure with a low-energy way to convert aluminium and magnesium waste into high value aerogels for the construction industry.

To do this, they ground the metal waste into a powder and mixed it with chemical cross-linkers. They heated this mixture in an oven before freeze-drying it and turning it into an aerogel. The team says this simple process makes their aerogels 50% cheaper than commercially available silica aerogels.

Aerogels have many useful properties. They are absorbent, extremely light (hence the frozen smoke nickname), and have impressive thermal and sound insulation capabilities. This makes them useful as thermal insulation materials in buildings, in piping systems, or for cleaning up oil spills. However, the NUS team has loftier goals than that.

There is a great need for less energy intensive ways to recycle metals

“Our aluminium aerogel is 30 times lighter and insulates heat 21 times better than conventional concrete,” research team leader Associate Professor Duong Hai-Minh whose research has been published in the Journal of Material Cycles and Waste Management. “When optical fibres are added during the mixing stage, we can create translucent aluminium aerogels which, as building materials, can improve natural lighting, reduce energy consumption for lighting and illuminate dark or windowless areas. Translucent concrete can also be used to construct sidewalks and speed bumps that light up at night to improve safety for pedestrians and road traffic.”

The aerogels could even be used for cell cultivation. Professor Duong explains: “Microcarriers are micro-size beads for cells to anchor and grow. Our first trials were performed on stem cells, using a cell line commonly used for testing of drugs as well as cosmetics, and the results are very encouraging.”

Whatever about these speculative applications, this upcycling method will hopefully help us find new homes for all types of metal waste including metal chips and discarded electronics.

Recyclable printed electronics

A team at Duke University has also made interesting progress in reducing electronic waste. The researchers claim to have developed fully recyclable printed electronics that could be used and reused in a wide range of sensors.

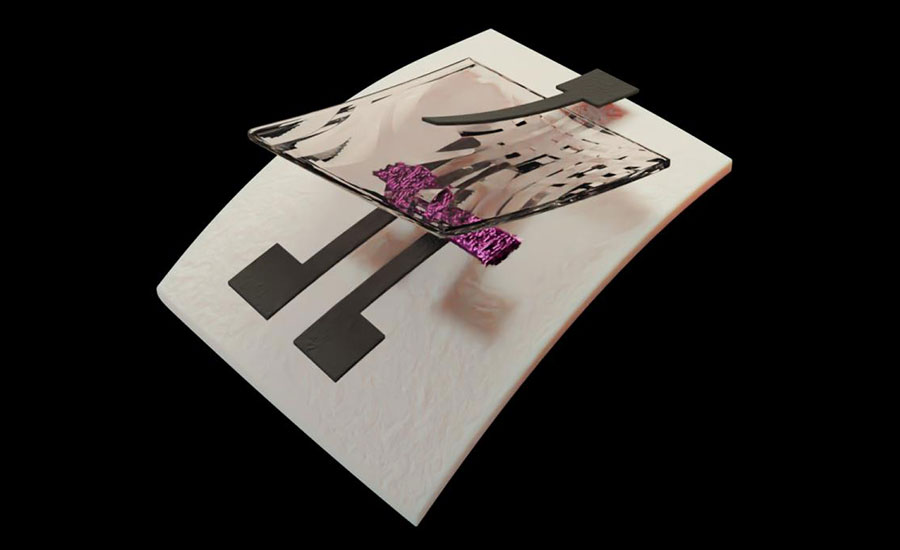

The researchers’ transistor is made from three carbon-based inks that can be printed onto paper, and their use of a wood-derived insulating dielectric ink called nanocellulose helps make them recyclable. Carbon nanotubes and graphene inks are also used for the semiconductors and conductors, respectively.

A 3D rendering of the first fully recyclable, printed transistor. CREDIT: Duke University

“Nanocellulose is biodegradable and has been used in applications like packaging for years,” said Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, whose research has been published in Nature Electronics. “And while people have long known about its potential applications as an insulator in electronics, nobody has figured out how to use it in a printable ink before. That’s one of the keys to making these fully recyclable devices functional.”

The team has developed a way to suspend these nanocellulose crystals (extracted from wood fibres) with a sprinkling of table salt to create an ink that performs well in its printed transistors. At the end of their working life, these devices can be submerged in baths with gently vibrating sound waves to recover the carbon nanotubes and graphene components. These materials can be reused and the nanocellulose can be recycled just like ordinary paper.

The team conceded that these devices won’t ruffle the trillion dollar silicon-based computer component market, but they do think these devices could be useful in simple environmental sensors to monitor building energy use or in biosensing patches to track medical conditions.

Read about the Duke University research here: https://www.nature.com/articles/s41928-021-00574-0

Take a look at the NUS study here: https://link.springer.com/article/10.1007/s10163-020-01169-1