In her winning essay in SCI Scotland’s Postgraduate Researcher competition, Rebecca Stevens, Industrial PhD student with GSK and the University of Strathclyde, talks about the potential of PROTACS.

Each year, SCI’s Scotland Regional Group runs the Scotland Postgraduate Researcher Competition to celebrate the work of research students working in scientific research in Scottish universities.

This year, four students produced outstanding essays in which they describe their research projects and the need for them. In the third of this year’s winning essays, Rebecca Stevens discusses her work in developing a multistep synthetic platform for Proteolysis Targeting Chimeras (PROTAC) synthesis and the potential of PROTACS in general.

Pictured above: Rebecca Stevens

A ‘PROTAC-tical’ synthetic approach to new pharmaceutical modalities

PROTACs are a rapidly evolving new drug modality that is currently sparking great excitement within the pharmaceutical and biotechnology industries.

Despite the first PROTAC only being reported in 2001, 12 of these potential drugs have already entered phase I/II clinical trials. In fact, a handful of new biotechnology companies have launched in the last two decades with a primary focus on these molecules. So, what’s so special about them?

Traditional drug discovery relies on optimising small-molecules to inhibit the action of a protein target and subsequently elicit a downstream effect on cellular function. However, many proteins are not tractable to this approach due to their lack of defined binding sites. This is where PROTACs offer a unique opportunity to target traditionally ‘undruggable’ parts of the proteome; instead of inhibiting the protein, PROTACs simply remove it altogether.

PROTACs are heterobifunctional molecules made up of two small-molecule binders attached together via a covalent linker; one end binds to the protein of interest and the other to an E3 ubiquitin ligase.

Rebecca is working on a multistep platform for PROTAC synthesis.

By bringing these two proteins into close proximity, PROTACs exploit the body’s own protein degradation mechanisms to tag and degrade desired proteins of interest in a method known as ‘targeted protein degradation’.

This different mechanism of action offers some revolutionary advantages over small-molecule drugs. Alongside potentially accessing ‘undruggable’ targets, PROTACs can overcome resistance mechanisms from which other drugs suffer, as well as acting in a catalytic manner, ultimately requiring less compound for therapeutic effects and maximising profits.

>> SCI’s Scotland Group connects scientists working in industry and academia throughout Scotland.

Problems with PROTACS

While great in theory, the reality is that with two small-molecule binders and a linker, PROTACs are typically double the size and complexity of normal drugs, so their synthesis is far from simple.

Classic drug discovery programmes often make many bespoke analogues alongside their use of library synthesis, using a design-make test cycle to optimise hits and find a lead molecule. With PROTACs, linear synthetic routes are much longer for bespoke compounds, underlining an even greater need for new PROTAC parallel synthesis platforms.

>> Read Marina Economidou’s winning essay on palladium recovery

Additionally, the design of PROTACs is more challenging as there are three separate parts of the structure to optimise, and small changes can have a large impact on their biological activity. As such, very simple chemistry is used to connect the three parts of the molecule, resulting in limited chemical space for exploration, causing potentially interesting bioactive compounds to be missed.

A platform for PROTAC synthesis

My PhD project seeks to develop a multistep synthetic platform for PROTAC synthesis, using modern chemical transformations such as C(sp2)-C(sp3) cross-couplings and metallaphotoredox chemistry.

Starting from already complex intermediates in the synthetic route, methods for late-stage functionalisation are under development to complete the final synthetic steps. By making elaborate changes at a late stage, a variety of structurally diverse PROTACs can be synthesised from a single building block, offering an economical and sustainable approach to optimisation for the industries involved.

Furthermore, the purification step prior to testing will be eliminated, with crude reaction mixtures taken into cells in an emerging ‘direct-to-biology high-throughput-chemistry’ approach. This removes a key bottleneck associated with hit identification and lead optimisation, delivering biological results in very short turnaround times.

The synthetic methods developed in the project will offer new capabilities for efficient and sustainable synthesis of PROTACs and other related modalities. Increasing the pace of data generation could accelerate the exploration of structure-activity relationships and deployment in large parallel arrays could provide a significant quantity of data to inform new machine learning models.

Ultimately, for industry, this ‘PROTAC-tical’ approach offers a huge opportunity for rapidly progressing PROTAC projects and discovering novel PROTACs with clinical potential.

>> Our Careers for Chemistry Postdocs series explores the different career paths taken by chemistry graduates.

The Commonwealth Games has landed in Birmingham. Before the Games began, viewers were treated to an extraordinary opening ceremony (featuring a giant mechanical bull) and its artistic director, Iqbal Khan, was lauded for his ingenuity.

But such ingenuity shouldn’t surprise any of us, for Birmingham has long been a place of outsized invention. For more than 300 years, the inhabitants of this industrial powerhouse have churned out invention after invention; and its great pragmatists have turned patents into products.

Chemistry, too, owes a debt to the UK’s second city. Whether it’s the first synthesis of vitamin C, the invention of human-made plastic, adventures in mass spectrometry, or electroplated gold and silver trinkets, Birmingham has left a lasting legacy.

Here are five chemists whose innovations may have made an appearance in your life.

Alexander Parkes – man of plastic

Plaque commemorating Alexander Parkes in Birmingham, England. Image by Oosoom

Look around you. Look at the computer screen, the mouse button you click, and the wire casings everywhere. Someone started it all. That man was Alexander Parkes, inventor of the first human-made plastic.

The son of a brass lock manufacturer from Suffolk Street, Birmingham, Parkes created 66 patents in his lifetime including a process for electroplating delicate works of art. However, none were as influential as the 1856 patent for Parkesine – the world’s first thermoplastic.

Parkes’ celluloid was based on nitrocellulose that had been treated by different solvents. In 1866, he set up the Parkesine Company at Hackney Wick, London, but it floundered due to high cost and quality issues. The spoils of his genius would be enjoyed by the rest of us instead.

Sir Norman Haworth – the vitamin seer

Sir Norman Haworth

Sir Norman Haworth may have been born in Chorley, Lancashire, but his finest work arguably came after he became Director of the Department of Chemistry in the University of Birmingham in 1925. Haworth is famous for his groundbreaking carbohydrate investigations and for being the first to synthesise vitamin C.

By 1928, Haworth had confirmed the structures of maltose, cellobiose, lactose, and the glucoside ring structure of normal sugars, among other structures. Apparently, his method for determining the chain length in methylated polysaccharides also helped confirm the basic features of starch, cellulose, and glycogen molecules.

However, Haworth is most famous for determining the structure of vitamin C and for becoming the first to synthesise it in 1932. The synthesis of what he called ascorbic acid made the commercial production of vitamin C far cheaper – the benefits of which have been felt by millions of us.

For his achievements in carbohydrates and vitamin C, Haworth received the Nobel Prize for Chemistry in 1937 (shared with Paul Karrer). He was the first British organic chemist from the UK to receive this honour. Haworth even had a link to SCI, having been a pupil of William Henry Perkin Junior in the University of Manchester’s Chemistry Department.

Francis William Aston – adventures in mass spectrometry

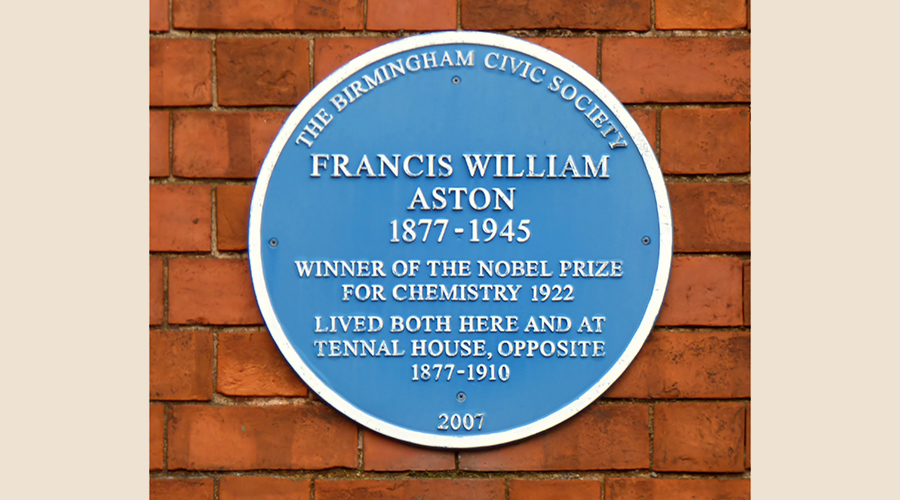

Blue plaque for Francis William Aston. Image from Tony Hisgett

Another Nobel Prize-winning chemist from Birmingham is Francis William Aston. The Harborne native won the 1922 prize for discovering isotopes in many non-radioactive elements (using his mass spectrograph) and for enunciating the whole number rule.

For a time, academia almost lost Aston, as he spent three years working as a chemist for a brewery. Thankfully, he returned to academic life and obtained concrete evidence for the existence of two isotopes of the inert gas neon before the first World War.

After working for the Royal Aircraft Establishment during the Great War (1914-18), he resumed his studies. The invention of the mass spectrograph proved pivotal to his discoveries thereafter. Using this apparatus, he identified 212 naturally occurring isotopes.

George Elkington and John Wright – all that glitters

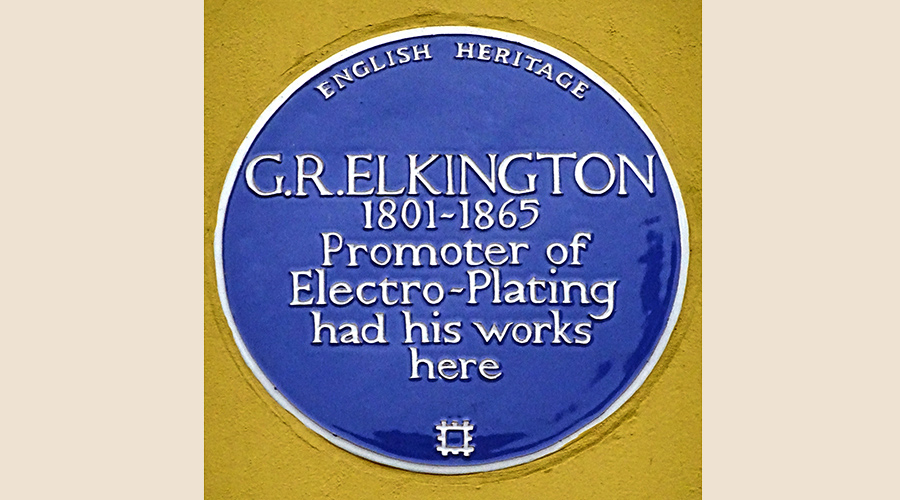

George Elkington patented the electroplating process developed by John Wright. Image from Spudgun67

It isn’t surprising that George Elkington should become an SCI favourite, as he blended both scientific ingenuity with business. The son of a spectacle manufacturer patented the first commercial electroplating process invented by Brummie surgeon John Wright in 1840.

Wright discovered that a solution of silver in potassium cyanide was useful for electroplating metals. Elkington and his cousin Henry purchased and patented Wright’s process before using it to improve gold and silver plating.

The Elkingtons opened an electroplating works in the city’s now famous Jewellery Quarter where they electroplated cutlery and jewellery. And they didn’t do too badly out of it. By 1880, the company employed 1,000 people in seven factories.

Alfred Bird – winging it

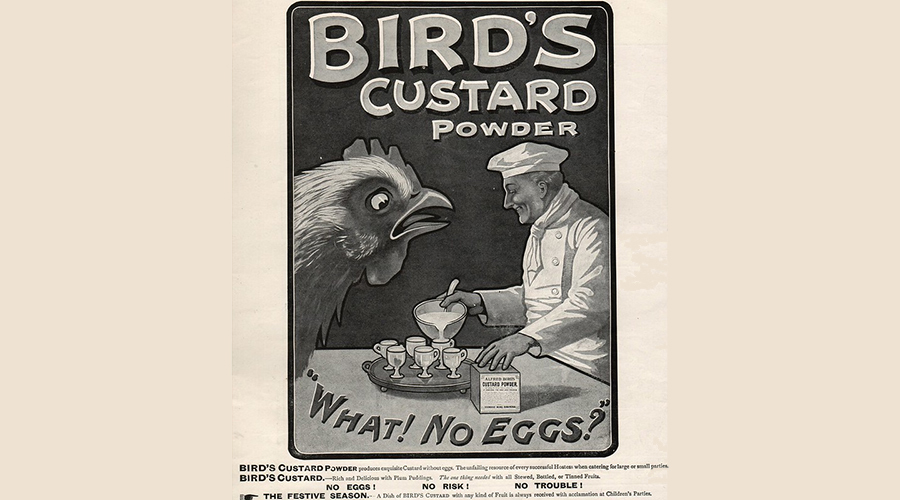

1906 advertisement for Birds Custard powder. Image from janwillemsen

In 1837, Alfred Bird was in a pickle. He wanted to serve his dinner party guests custard, but his wife was allergic to eggs and yeast, and egg was the main thickening agent of this delicious gloop.

Instead of serving something else, the chemist shop owner invented his own egg-free custard by substituting cornflour for eggs. His guests found it delicious and Bird’s Custard was born.

Not content with this innovation, Bird is also credited with being the father of modern baking powder. Once again, his wife’s allergies were said to be the inspiration, as he wanted to create a yeast-free bread for her. In bread and custard, true love always finds a way.