BY LOU READE

Chemists are finding new ways to make wood stronger, which could pave the way for new applications in sensors, satellites and even transparent wood to replace window glass, reports Lou Reade.

Wood has a long history as a construction material. However, its limited mechanical performance means that other materials like metals and composites are often preferred. Now, a growing body of research is finding ways to modify wood and increase its physical strength. Most methods involve chemically removing one of its key components – lignin – to leave a stronger, tougher material. Improving the properties of wood could extend its use into new areas. Traditionally used to make furniture and houses, in future wood may find use in sensors and satellites – with some researchers claiming it can be made as strong as steel.

Transparent benefit

Transparent wood has been the subject of research since the early 1990s. Now, scientists at Kennesaw State University in Georgia, US, have prepared their own version, which they claim is fully biodegradable. Transparent wood is created by chemically removing lignin and hemicellulose, leaving just cellulose. This creates ‘voids’ in the wood structure. Most research has used epoxy or other colourless polymers to fill these voids – which adds rigidity and maintains translucency. However, chemistry professor Bharat Baruah took inspiration from India, where some ancient buildings were constructed using a cement made from sand, egg whites and rice water.

‘By replacing epoxy resin with an egg white and rice water mix, we made transparent wood completely biodegradable,’ Baruah says.

Creating the transparent wood involves several steps. First, Baruah took a piece of balsa wood and soaked it in a mixture of sodium sulfite, sodium hydroxide and diluted bleach. This broke down the lignin and hemicellulose, which are removed by applying a vacuum. The egg white and rice extract is then infused into the delignified wood. The sample is dried at 45-50°C between two sheets of glass, creating a translucent paper-like sheet.

Baruah has investigated various potential applications. One is to replace conventional window glass, as transparent wood absorbs infrared radiation and offers superior insulation. To demonstrate this, Baruah built a small wooden bird house with a transparent wood window and measured the internal temperature while shining an infrared lamp onto it.

‘It was 5-6°C cooler when we replaced a glass window with transparent wood,’ Baruah says.

He also prepared conductive samples by incorporating silver nanowires into the structure. These are created by dotting silver particles onto the surface, which form zig-zag shaped ‘circuits’. This could be used as the basis of a wearable sensor, he says – such as by incorporating the transparent wood into a pair of glasses. Although early days, he has already met the university’s commercialisation arm. Baruah presented his results at the ACS Spring meeting in March 2025 – and is currently writing a research paper.

Biodegradable ‘transparent wood’ could be used in wearable electronics

BHARAT BARUAH

Pressed into service

Meanwhile, US researchers are working out how cellulose fibres from wood and cardboard could create rigid materials. US military research organisation DARPA has funded a $2m project called Waste Upcycling for Defense (WUD). The aim is to use cellulose from scrap such as wooden crates and cardboard packaging to make a 4ft x 8ft sheet that is ‘as strong as steel’. This could be used as a construction material on army bases. In the first step, lignin is removed. Then the resultant material is pressed tightly to align the fibres. This promotes hydrogen bonding and imparts extra strength.

‘I don’t think people fully appreciate the strength of wood biomass in the absence of lignin,’ says Project Leader Art Ragauskas, of the department of chemical and biomolecular engineering at the University of Tennessee, US.

The challenge here is to make the material from mixed waste – rather than solid pieces of timber. One key partner is Cyrus Aidun at Georgia Institute of Technology, US, who has developed a way to align the fibres – using a modified paper machine – before the pressing stage. The eventual plan is to make the new material on any army base in a continuous process.

The extracted lignin will not go to waste. ‘We want to add it to the surface as a hydrophobic coating,’ says Ragauskas. ‘This will help it to survive for longer.’

A lignin coating would also lower the material’s flammability, he explains. The team has so far produced 1m2 boards. Researchers are testing the material’s physical characteristics such as tensile strength and will evaluate its suitability for processes such as cutting and drilling.

‘Converting waste wood into a high-performance board can minimise landfill needs and reduce the logistics of building materials, especially in remote areas,’ says Ragauskas.

Self-densification

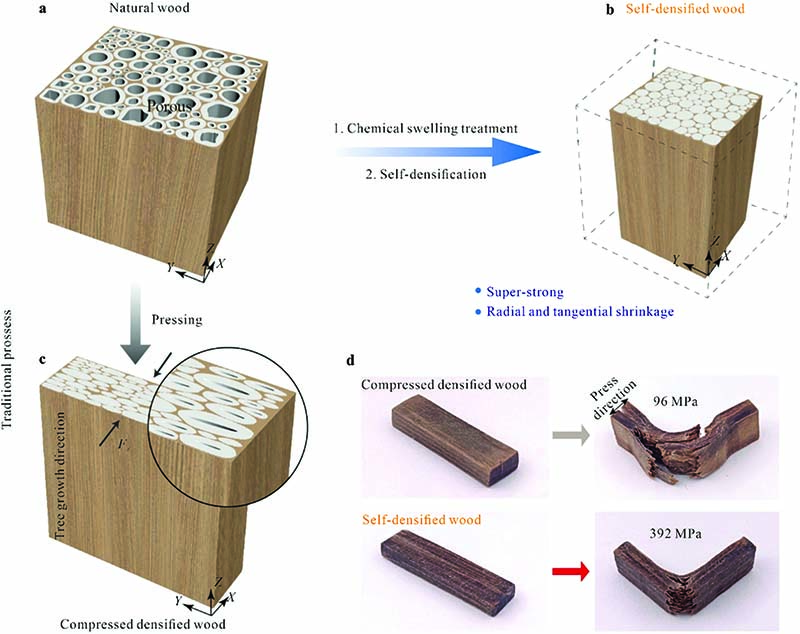

Meanwhile, researchers in China have developed a method to make ‘self-densified’ wood, which they say could replace metals and alloys. A team at Nanjing University, led by Dafang Huang and Jie Li, used partial delignification and a process called LiCl/DMAc swelling to release and reorganise wood fibres. They say this is more effective than previous methods that rely on hot pressing.

Wooden blocks were immersed in a lignin-removal solution (sodium hydroxide and sodium sulfite) then washed in water. The partially delignified wood was then immersed in N,N-dimethylacetamide (DMAc) to activate wood cellulose. Lithium chloride (LiCl) was added, and a swelling reaction took place at 100°C. Finally, the wood was air-dried at room temperature and shrank spontaneously to form self-densified wood. Unlike traditional compressed wood, which uses ‘unidirectional compression’, this method has uniform shrinkage – allowing it to maintain mechanical properties in all directions, say the researchers. The self-densified wood had a tensile strength of 496MPa – nine times that of the original wood sample (55MPa).

The researchers say a uniform microstructure and enhanced hydrogen bonding between cellulose fibres contribute to the performance. They believe the wood could replace traditional structural materials in applications such as construction. A wooden nail fabricated from their material outperformed steel nails in load-bearing tests[1].

Nanjing University researchers say their ‘self-densified’ wood could replace metals and alloys

National Laboratory of Solid State Microstructures & Jiangsu Key Laboratory of Artificial Functional Materials & Department of Materials Science and Engineering, College of Engineering and Applied Sciences, Nanjing University, Nanjing 210093, China.

Coating protection

Extending the lifetime of wooden components often involves a surface coating such as paint or varnish or creosote. However, the coating itself is also prone to damage. Now, researchers in Japan have developed a new way of assessing coating degradation at a very early stage.

‘We are detecting subtle changes in molecular structure that occur before any visible damage, such as cracking or peeling,’ says Yoshikuni Teramoto, Associate Professor in the division of forest and biomaterials science at Kyoto University and lead author of a 2025 study explaining the research[2].

Conventional detection relies on visible defects such as discolouration, gloss loss or peeling, he says, while others involve destructive adhesion tests – making repeated measurements at the same location impossible.

The new method uses a non-destructive technique called attenuated total reflectance Fourier-transform infrared spectroscopy. The twist is that it uses mid-infrared radiation, with a wavelength of 3-8µm that is very sensitive to functional groups like carbonyl, hydroxyl and carbon-hydrogen bonds.

‘Unlike visible light or near-infrared, it provides direct molecular information,’ Teramoto says.

Carbonyl oxidation is a well-known indicator of degradation in waterborne acrylic coatings. While conventional analysis often uses absorbance ratios of spectral peaks, Teramoto says this approach detects more subtle changes that may be missed by simple spectral comparison. It can also pinpoint other changes that occur before visible failure, including hydroxyl increase and loss of aromaticity.

The technique generates a ‘predicted degradation score’, expressed as equivalent hours of accelerated weather testing. For example, 500 hours of xenon arc exposure is often equated to one year of outdoor exposure. The degradation score can act as a scientific indicator for repainting or maintenance.

‘If latent degradation is detected, timely intervention – such as recoating – can prevent further damage,’ Teramoto says. ‘This reduces long-term costs and preserves appearance.’

He believes the technique has strong commercial potential, especially in building maintenance and paint manufacturing. ‘We are already conducting joint research with industry partners.’

By combining handheld ATR-FTIR devices with a customisable analysis workflow using standard software tools, the team aims to enable on-site, real-time diagnosis within the next three years.

Since the paper was published, the researchers have begun experimenting on other coating types and conducted field tests on buildings. They have also launched projects to test and refine the method under practical conditions, Teramoto says.

Cascade effect

With or without modification, demand for wood will rise in future thanks to its renewable nature. While wood can be regrown, however, it is not a limitless source. Renewable does not automatically equal sustainable.

In the UK, for instance, there was a sharp increase in the amount of softwood harvested in 2024 – up 9% to nearly 10m t. Softwood (coniferous trees) accounted for 92% of removals from UK woodland.

This is part of a much larger pattern, with global demand for timber likely to quadruple by 2050, according to a report from the World Bank. Using forests to store CO2 while simultaneously harvesting them for a renewable building material will require a delicate balance and careful use of resources.

Swiss researchers say they have devised a way to maximise the use of wood by tracking it across all types of applications. The researchers, from materials science research institute Empa, say that in a ‘wood cascade’, a harvested tree is first processed into the largest possible product, such as beams or boards for construction. When it can no longer be reused in this way, it is turned into smaller boards, wood chips or wood-based materials – and is only burnt when it can no longer be used as a material.

‘For wood to fulfil its function as a long-term CO2 sink, it should remain as a material for as long as possible,’ says Claudia Som, a researcher at Empa[3].

The study was based on Swiss statistics on timber harvesting, recycling and disposal, which is an advantage over comparable studies that rely heavily on modelling, say the researchers. The research forms part of a larger project called Scene (Swiss Center of Excellence on Net-Zero Emissions) – a joint initiative of six institutions to support Switzerland’s goal of achieving net zero by 2050.

Wood is a long-established building material, with evidence suggesting it was first used in construction 476,000 years ago[4]. As the need for sustainable practices increases its appeal, we must find a way to use it judiciously – and, if necessary, enhance its properties.

Flying high

Japan has taken its long tradition of woodworking to a new level – by launching a wooden satellite into space. The satellite, called LignoSat, was developed at Kyoto University for the Japanese Aerospace Exploration Agency (JAXA) and launched in December 2024. It used wood from the honoki tree, a type of magnolia, which was chosen after an earlier project where wood samples were sent into space and studied.

LignoSat, measuring just 10cm on each side, was assembled from honoki panels using a Japanese wood-joining technique that uses no nails or screws. This was vital, because wood is likely to warp in the temperature extremes of space.

There were other reasons for avoiding metal. One is that a wooden satellite will generate fewer toxic substances when it burns up on re-entry than, say, one based on aluminium where the byproduct, aluminium oxide, has been implicated in ozone depletion. In addition, electrical waves pass easily through wood, allowing antennas and other components to be housed within the cube.

The researchers wanted LignoSat to measure its own structural deformation, internal temperature distribution and transmit the data back to Kyoto University – but were unable to communicate with it. Despite this, the scientists have not given up. They are now building LignoSat-2, which is twice the size of its predecessor.

References

- J. Biores. and Bioprod., 2025, DOI: 10.1016/j.jobab.2025.03.001

- Adv. Sust. Syst., 2025, DOI: 10.1002/adsu.202401052

- Industrial Ecology, 2024, DOI: 10.1111/jiec.13560

- Nature, 2023, DOI: 10.1038/s41586-023-06557-9

Main picture: The Grand Ring – created for the Osaka 2025 Expo event in Japan – has been recognised as the world’s largest wooden architectural structure by Guinness World Records. The circular construction – 675m in diameter and 2km in circumference – surrounds the entire Expo venue and is topped by a 12m-high walkway called the Sky Walk. It is made from two local woods (cedar and cypress) and imported Scots pine, using modern construction methods and traditional Nuki joints – such as those used in shrines and temples. Originally designed to be dismantled when the Expo ends in October 2025, it may now be kept in place.