Nature’s wetlands are brilliant at cleaning up wastewater. Litre for litre, artificial ecosystems created with wetland plants and microbes are 1/20th the cost of standard municipal wastewater treatment plants. But they are also hugely land intensive, and designed to treat and release water, rather than to reuse and recycle it, according to NuLeaf Tech CEO Rachel Major, speaking at the EFIB meeting in Brussels in October 2017.

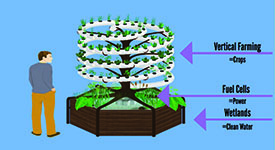

NuLeaf’s innovation has not only been to scale down the technology, but to also grow crops. And to couple the system to a microbial fuel cell (MFC) to power the associated lighting and water pumps.

‘We bottle Nature’s genius into a compact modular unit that can treat thousands of litres per day of both solid and liquid waste without odour,’ Major said. ‘A MFC makes the system self-powered, and the nutrient-rich water created can be used to grow crops.’

The company’s NuTree compact system minimises precious space requirements for expensive wastewater treatment as well as agriculture by growing crops year-round in stacked layers in indoor greenhouses. Each module is ca2m3 in size and costs around $10,000/unit, while more can be added depending on the scale of the clean-up operation.

‘They don’t have the biodiversity or the carbon sequestering power of a full-scale wetland system, but they are more or less the same,’ Major said. ‘More complex waste is broken down in the wetland and the simpler waste is processed in the fuel cells as a polishing step.’

The engineered wetlands component is an improved version of constructed wetlands, she continued, which typically employ reed beds that mimic the natural functions of vegetation, soil and microorganisms to treat wastewater, for example by filtering out pollutants such as heavy metals and sediments. They are also capable of removing organic hydrocarbons, as well as transforming nitrogenous and phosphorus waste into liquid fertiliser.

The added MFCs harness bacteria to produce energy from waste via a series of redox reactions. At the cell anode, bacteria break down glucose, acetate etc to release energy-rich methane and protons (H+), as well as electrons. Electrical current is created as the protons move from the anode to the cathode, which in turn causes the electrons to flow. In the cathode, different bacteria use the protons and electrons in a chemical reaction that creates pure water. In future, Rachel notes that NuLeaf intends to use the MFCs to create potable water and make the system energy positive.

Major and her cofounder Ari Ochoa first tried out their engineered wetland technology earlier in 2017 at the University of Cork in Ireland. ‘The first system used aquaponics to transform fish waste into nutrients,’ Rachel said. ‘It circulated over 2000L and removed 99.99% of nitrogenous waste while keeping the pH at 7-7.5 and BOD [biological oxygen demand] steady at around 1.5mg L-1.’

The pair connected a 2000L fish tank, a 2mx1m engineered wetland and a 2mx1m hydroponic grow bed in the university’s community garden. Waste produced by the fish was treated by the wetland to produce nitrate and phosphorus fertiliser compounds that were then passed to the hydroponic plants to be used as nutrients, while clean water was cycled back to the tank.

NuLeaf is in negotiations to sell the system to the university, and also in talks to sell its first vertical - Nutree - system to a brewery in Scotland. ‘Our entry market is craft beer,’ Major said. ‘Breweries create a lot of wastewater that municipal wastewater plants can’t normally treat. Some breweries pay millions in off-site wastewater treatment costs.’

Compared with municipal wastewater, brewery wastewater is high in sugar and alcohol, as well as high temperature. Major estimates the Scottish brewery would require one to two NuTree modules to treat about 1500L/day of wastewater. ‘The NuTrees will also have an aquaponics set up, so fish can be sold to further increase brewery profits,’ Major noted, adding that current estimates show the brewery will have a return on investment in two years.

‘This is certainly interesting technology,’ commented Geoff Sweaney, chair of the Constructed Wetland Association. ‘While the idea of coupling a constructed wetland to a MFC is not totally novel, I’m not aware that anyone has previously attempted to do so commercially. However, one question mark would be over how much energy their MFC produces. I’ve no idea how much energy you would get out of wastewater in this way – I suspect not a huge amount, but it would depend on the amount and strength of wastewater being treated.’

NuLeaf is aiming to raise $300k to market and implement more pilot systems in breweries and make the Nutree units modular by the end of 2018. Distilleries and wineries could be the next targets, and beyond that Major says other potential markets are treating agricultural wastewater, rural living and biorefinery waters.

Further in the future, we could even see a NuTree system in our own homes - for cleaning up and recycling household wastewater in increasingly populated and water-scarce cities.