Each year SCI’s Scotland group a runs competition where students are invited to write a short article describing how their PhD research relates to SCI’s strapline: where science meets business.

Jack Washington (right), a Pure and Applied Chemistry PhD student at the University of Strathclyde, was the overall winner of this year’s competition. His article ‘Clavulanic acid - The fight against antibiotic resistance’ is reproduced here:

Clavulanic acid - The fight against antibiotic resistance

If you were to say that cancer is the biggest threat to public health you would be wrong.

One of the most pre-eminent risks to human existence is antibiotic resistance. Antibiotics are medicines used to fight bacterial infections. However, bacteria are fighting back at an alarming rate. Without effective antibiotics, we could live in a world where infections borne from a simple wound could be deadly. Routine surgeries would no longer be possible. Whilst this bacterial apocalypse seems drastic, it’s a very real possibility, and one we could face in the near future.

Antibiotics are part of a multibillion-pound industry and are essential for life as we know it today. In 1928, the scientist Alexander Fleming, from Ayrshire in Scotland, serendipitously discovered penicillin. This chance discovery revolutionised the treatment of bacterial infections and spurred a wealth of antibiotic research. 88 years later, in the nearby town of Irvine, I started my PhD project in this field.

Penicillin is a β-lactam antibiotic, which made up of molecules containing a chemical entity known as a β-lactam. This β-lactam is a covalent warhead – a harpoon that grips its bacterial victim and doesn’t let go. This harpoon interrupts bacterial cell wall formation, causing the bacteria to rupture and die. However, bacteria can retaliate by producing aggressive enzymes that destroy this warhead. Another member of the β-lactam family, clavulanic acid, can thwart these enzymes. Clavulanic acid has weak antibiotic activity on its own so is used in a double act with another antibiotic, amoxicillin, to fight antibiotic-resistant bacteria as a team.

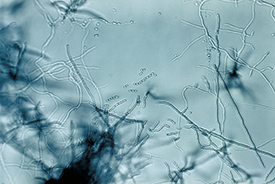

My PhD focuses on the industrial production of clavulanic acid, a complex molecule best made by nature. Industrially, it is made by fermentation of Streptomyces clavuligerus. The molecule is then taken through an intricate extraction from a broth to deliver clavulanic acid, safe for consumption and in the huge quantity that meets its high global demand. The β-lactam ring (the harpoon) in clavulanic acid is deadly to the bacterial enzymes it targets, but it presents challenges for its process-scale production. Clavulanic acid is susceptible to degradation during extraction from the broth, causing a loss in valuable yield and adding costly purification steps to the overall process.

Though clavulanic acid is an established product, its degradation process is not fully understood. I am studying the effects of temperature and pH on the degradation of clavulanic acid both in sterile solutions and samples taken directly from the process stream. These investigations have enabled the identification of pH and temperature ranges wherein the degradation of clavulanic acid is minimised at each part of the extraction procedure. This information alone, however, is not sufficient to implement changes to the manufacturing process. A challenge that will be faced in this project is finding suitable conditions to mimic stages of the process on a laboratory scale. The optimal physical parameters in terms of degradation and extraction efficiency may not necessarily be the same.

Through ongoing research, I aim to help find improved operating conditions that reduce loss of precious clavulanic acid to degradation. Being based at an industrial manufacturing site means I can see how product yields directly influence the price of clavulanic acid in the market. Improving the overall recovery from the initial broth will not only have financial benefits for the manufacturer, but also to end-users who require the antibiotics. My research impacts chemical manufacturer and consumer alike, and it is at this bridge between worlds, between science and business, that the fight against antibiotic resistance rages on.