Obtaining an accurate idea of food shelf life is key to setting reliable 'best before' and 'use by' dates – and to minimising the amount of food that is wasted, writes Persis Subramaniam

Food waste is an increasingly important issue for governments looking for answers to the problem of how to feed the world’s burgeoning population. In the UK, roughly a third of the food we buy ends up being wasted, according to the government waste body WRAP. Much of this is currently sent to landfill where it contributes to the formation of methane – a powerful greenhouse gas with more than 20 times the warming potential of carbon dioxide. If we stopped throwing away all this food, it is estimated that this would have the equivalent effect of taking one in five cars off the road.

The problem of food waste

Food ‘use by’ and ‘best before’ dates have an important role in helping consumers to decide when food is safe or of sufficiently high quality to eat. Short shelf-life products, where the deterioration is caused by the growth of microorganisms, are labelled with a ‘use by’ date, while ambient stored products with a long shelf-life have a ‘best before’ date. However, concerns about the problem of food waste have now brought these labels under greater scrutiny. The UK’s Food Standards Agency (FSA) has just carried out a consultation to review its guidance on date markings, with the aim of updating its guidance for compliance with food labelling regulations.1

Critical to setting these date labels is an accurate assessment of food shelf-life, which is defined as the period of time after manufacture that the product remains safe and fit to eat under defined storage conditions. For products that do not deteriorate because of microbial growth, safety is not an issue and cut-off points for quality are set by the manufacturer based on one or more of attributes covering the appearance, flavour and texture/mouthfeel of the products.

Other chemical tests to measure indicators of food quality have mainly focused on measuring fat oxidation and rancidity development. Rancidity development reflects the deterioration in products that contain a substantial level of fat, such as biscuits and fried snacks. Various methods have been used to measure fat oxidation2,3 and to correlate this with sensory effects.

However, a general problem with testing procedures is that real time tests to the point of failure are not possible for products with a long shelf-life. A consequence is that products are given a more conservative shelf-life, indicated by the ‘best before date’, to ensure that the product will always remain in good quality as it reaches the consumer. A consequence of this is that some foods that could be eaten are thrown out and therefore more accurate measurement of shelf-life will lead to a reduction in food wastage.

Food manufacturers see the use of instrumental data as an unbiased independent route for measuring and ultimately predicting shelf-life using models. Identifying techniques that have good correlation of with sensory analysis is key to achieving this goal and is the focus of a study currently being carried out at Leatherhead Food Research in Surrey, UK. Our approach has involved measuring the sensory changes occurring in biscuits and juice-based drinks, identifying sensory cut-off points for product failure and relating the results to analytical results. Since an important quality change occurring with time is flavour and odour, GC-MS was enlisted as a useful technique to identify volatile flavour compounds and measure how their concentrations changed over the product shelf-life. This information could then be used to identify the failure mechanisms for the products and identify specific markers for product deterioration. In addition, these markers would also be useful for investigating shelf-life extension.

Undoubtedly the most important tool in the analyst’s armoury for the identification and analysis of volatile organic compounds is GCMS. In this instrument, sample extracts are introduced into the head of the GC column, which separates out the component compounds over time. The end of the column is connected to the mass spectrometer, which records mass spectra of all the eluting compounds.

However, the method of preparing sample extracts for GCMS can have an impact on the results. The extracts should contain only the volatile compounds from the sample to avoid the deposition of non-volatile material inside the GC column, which can lead to loss of chromatographic resolution. The extraction should allow the concentration of the volatiles from the sample in order to maximise the sensitivity of the analysis but should not produce artefacts during the extraction procedure. Within these operating parameters, four extraction techniques are widely used for the analysis of food volatiles: combined solvent distillation and extraction (SDE); direct headspace analysis; dynamic headspace analysis; and solid phase microextraction (SPME).4

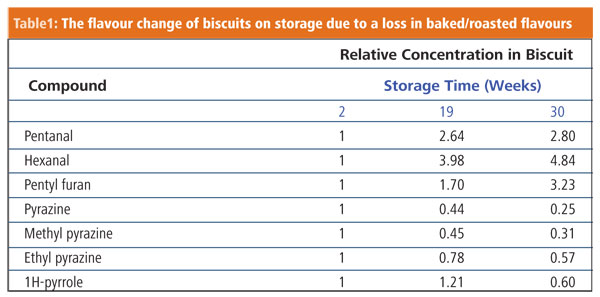

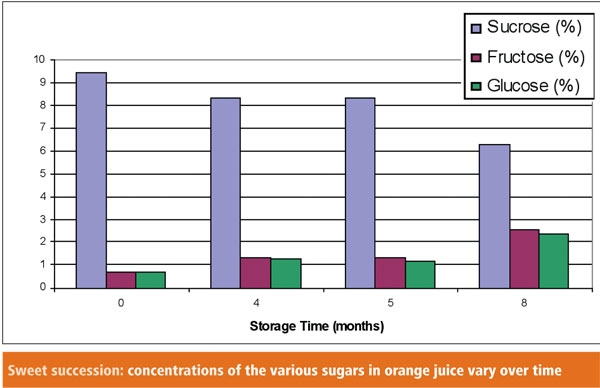

At Leatherhead, GCMS has been an important technique to identify markers for the deterioration of different soft drinks and biscuits. The project involved studying differences in products at the fresh, mid-life and end of life states. In the case of biscuits, the overall flavour change occurring on storage was found to relate to a loss in the baked/roasted flavours – as indicated by a reduction of pyrazines and pyrroles – and an increase in oxidation markers, for example, hexanal, pentanal and pentyl furan (Table 1). In the case of soft drinks, both sucrose inversion and loss of flavour compounds, for example, limonene in citrus drinks, correlated with instrumental measurements of colour using colorimeter and sensory changes measured using a trained panel (Figure 1).

Real time conditions

The next stage of the work will involve studying biscuit and soft drink products as they age under real time conditions using both detailed sensory and instrumental tests. There is still much to be learnt about markers for shelflife, but a systematic approach of identifying and measuring marker compounds will help in the quest for predictive tests for shelf-life. Predictive tests could indicate, at an early stage of storage, the type and likelihood of stability problems to be expected during long term storage of products. The use of accelerated storage tests, where products are stored under conditions that promote deteriorative changes, in combination with shelf-life markers can also be useful in assessing the stability of products within a shorter time scale.

Manufacturers are working under ever increasing time pressures to bring new products to market and real time storage tests are very often not possible. Predictive tests will help them to determine the stability of new recipes, measure packaging performance and investigate approaches for extending shelf-life within a shorter time frame. Products are normally tracked even after launch, to confirm that the shelf-life of products have been accurately set and that the products do meet consumers’ expectations throughout the storage period.

Some common methods for testing food shelf life

Peroxide value (PV) is useful in giving an early indication of rancidity development as hydroperoxides are formed in the early stages of lipid oxidation. This test has been commonly used to assess the shelf-life of products and has been correlated with sensory quality assessment of oils, and snack foods. An important point to note is that this method requires knowledge of the history of the product as it is possible to have low peroxide values even when the product is rancid owing to the breakdown of peroxides.

Free fatty acid (FFA) measurement is useful when related to flavour of products as they can have either a positive or negative effect depending on type of FFA present. FFAs affect the perception of rancidity either directly or by their subsequent oxidation. Some FFAs associated with off-flavours include free linoleic and linolenic acids, which have been associated with bitterness3; C4 and C6, which have been associated with rancid and ‘goat-like’ flavours; and C10 and C12, which have been associated with soapy and bitter flavours.

TBARS (Thiobatituric Acid Reactive Substances) is a method commonly used as an indicator of lipid oxidation particularly in meat and fish products. However, correlation of results from TBA (thiobarbituric acid) and TBARS tests with sensory results have been found to be variable, showing low to high correlation in different studies. It is suggested that other compounds present in food, such as sugars, acids, esters amino acids and oxidised proteins, could interfere with the test as they also react with TBA.

Anisidine Value (AV) can be measured alone or in combination with PV. Anisidine value is a measure of aldehyde levels in the oil or fat, in particular unsaturated fats, principally the 2-alkenals, and has been used to correlate with sensory data for fried snacks.

Totox (TV) can be determined from AV and PV where TV= 2PV+AV. For oils, a TV of less than 10 is suggested to be an indication of acceptable quality. TV has been shown to be a useful indicator of fat oxidation.

Gas chromatography (GC) has been used to measure oxidative rancidity and found to be useful in determining the volatile compounds in the headspace above the foods. Aldehydes, in particular hexanal, have been identified as a marker for oxidative rancidity and this remains the most commonly reported marker for rancid off-flavour.

Persis Subramaniam is project manager–product development at Leatherhead Food Research, Leatherhead, Surrey, UK.

References

1. http://www.food.gov.uk/multimedia/pdfs/consultation/ fsaguidancedatemarksfoodeng.pdf

2. Irwin, J.W. and Hedges, N., Measuring lipid oxidation in Understanding and measuring the shelf-life of food, ed R. Steele, pp 289. Woodhead Publishing, 2004.

3. Kristott, J., Fats and oils in The stability and shelf-life of food., ed D. Kilcast and P. Subramaniam, pp 279-307.Woodhead Publishing, 2000.

4. Ross C.F. and Smith D.M., Comp. Rev. Food Sci. Safety, 2006, 5, 18.