In the mid-1970s, Franklin & Associates, a US consulting firm, conducted a so-called Materials Flow Analysis for Coca-Cola. Franklin assessed American distribution of Coke in glass bottles, comparing recycling with disposal. The conclusion was that single use disposal was preferable, because it generated less waste and used less energy.

This was the first shot in a war of words, and consulting studies, over whether or not it is greener to recycle and this question has continued to crop up to this day. In the 1990s, the question flared up again in Germany, as mandatory recycling was introduced through take-back laws, which eventually spread to most countries in northern Europe.

While many studies have been made comparing one material to another, such as plastics to glass to aluminium, the simple question of recycling plastic versus landfill has not been tackled in years.

At SRI Consulting we decided to find an answer, not for all plastics, but for one part of the sector: polyethylene terephthalate (PET) drink bottles. PET bottles are a significant subsector; in 2009 global consumption was just over 15m t. We framed the question in the context of global warming, by simply posing the question: is the carbon footprint of recycling PET bottles greater or smaller than that of disposing of them in other ways? And the follow-up: what are the relative carbon footprints of virgin PET (vPET) and recycled PET (rPET)?

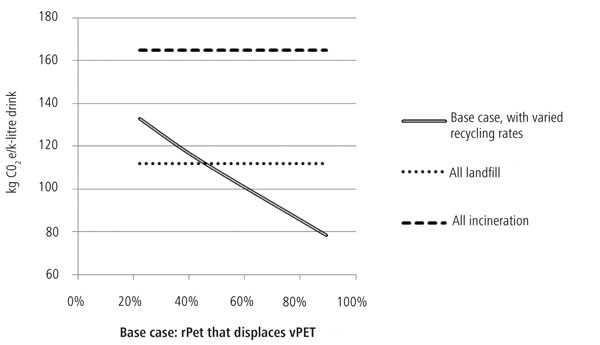

The results were surprising. If 45% or more of the PET originally sold is recycled in a closed loop, displacing vPET with rPET, then the carbon footprint of this packaging system will be lower than if the PET were simply sent to landfill. If less than 45% of PET goes into the closed loop, then the better low-carbon option is simply to landfill the bottles. Either of these options yields a substantially lower footprint than does incinerating all the PET waste (Figure 1).

As it happens, this 45% rate for PET is about what was achieved under Germany’s ‘Green Dot’ Duales System Deutschland kerbside system that used to collect PET bottles – we used its data in our analysis. From a carbon-emissions standpoint, it would be just as well to bury used bottles as to recycle them, and either would be a better option than burning them. Although incineration of waste can create a carbon credit through power generation, incinerators typically boast less than half the efficiency of a modern coal-fired power plant and also generate carbon dioxide.

A corollary to this is that transport is not a critical factor in the footprint. Our analysis assumes that vPET displacement takes place in China, and moving this to a location in Europe, where the bottles are used, would not substantially alter the result. Displacement of virgin material by recyclate, not transport, is the key variable.

So what is a policymaker or regulator to do? For places that already have a recycling infrastructure, the aim should be to boost rPET displacement of vPET significantly above 45%. The key is not in further increasing collection rates, which already have already reached around 80% in certain countries, but in improving yields, especially in sorting and to a lesser extent in reprocessing.

But the Germanic approach is admittedly expensive, and it requires serious consumer discipline – sorting household waste into numerous bins – that may be lacking in other parts of the world. For countries without a recycling infrastructure, the best choice may well be to landfill bottles. Call it carbon capture and storage, if you will, on a budget.

rPET versus vPET: which carbon footprint is lower?

In the main part of the study, we calculated the footprints of PET bottles, a packaging system that comprises not just PET but also other materials and processes involved in delivering carbonated drinks to consumers. This gave us carbon footprints associated with delivering drinks to consumers, but it also begged a related question of interest to participants along the entire supply chain: what is the footprint of PET resin at the plant gate, either for virgin PET or recyclate?

Although the method for calculating vPET’s footprint is straightforward, for rPET the calculation method is less obvious. To this we applied two methods, and two variations of one of them.

The traditional method for calculating the footprint or life-cycle inventory of a recyclate is:

- the virgin and recyclate production/use activities are defined as two different life cycles

- the recyclate’s system boundary begins at a sorting plant, with the raw material delivered ‘free’, that is without any initial carbon footprint

- the virgin system stretches from cradle-to-sorting

- the recyclate system stretches from sorting-to-grave

We followed these rules and for all products except fibre-grade PET, which is the primary target product, and we credited the displacement of other virgin products. As a variation on that, we also calculated the carbon footprint without the ‘incineration debit’ – the greenhouse gases emitted in burning waste – which arguably would happen anyway, even if the vPET were not recycled.

Another way to calculate the carbon footprint of rPET is to make the recyclate resin, rather than the packaging system, the objective function. Subtract one from the other, normalise by the amount of rPET produced, and this gives the answer.

In each method, the result was an rPET footprint smaller than vPET’s. However, the amount of difference is difficult to say with precision because the rPET footprints vary considerably by method. This topic should be explored further in future research.

Eric Johnson, editor of Environmental Impact Assessment Review, is based in Zurich, Switzerland. Mike Arne, director of SRI Consulting’s Greenhouse Gases Initiative, is based in Menlo Park, California, US.