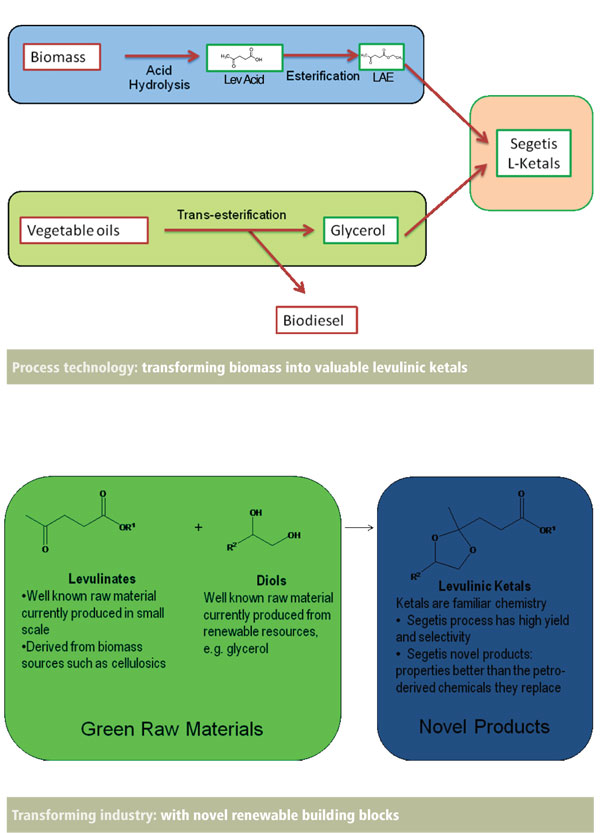

Levulinic ketals derived from plant biomass provide novel chemical building blocks that offer practical alternatives to petrochemicals, writes Snehal Desai

For decades, the $400bn global chemical industry has relied on fossil fuels. Indeed, the US chemical industry alone consumes more than 3m barrels of oil daily, a demand second only to transportation fuels. But as oil and gas reserves continue to be exhausted, and the issue of climate change gains ever more momentum, policymakers have increasingly begun turning to the world’s biomass reserves as an alternative source of feedstocks.

According to researchers at the Technische Universitat Darmstadt in Germany, based on information from sugar and wood industries, the world produces an estimated 180bn tonnes of renewable biomass annually, of which 75% is represented by carbohydrates.1 Only 4% of these valuable carbohydrates are currently used by man, while the rest is left to decay and recycle naturally.

Building blocks for a greener industry

Transforming this enormous biomass reserve into useful chemicals and products, however, will rely on fi nding simple and cost effective pathways that can compete with current petrochemical routes. In 2004, the US Department of Energy (DoE) attempted to make this task more easily navigable by compiling a shortlist of the top 12 sugar-derived building blocks – or bio-platform chemicals – that have the potential to be converted into a range of valueadded chemicals and materials.

One of the key chemicals on the DoE’s hitlist is levulinic acid, a fi ve-carbon building block derived from multiple cellulose and hemicellulose materials, including corn cobs, wood residues and sugar cane bagasse, by acid and thermal decomposition (see Box). A starting material for a wide range of higher value products, levulinic acid can be converted into chemicals such as acrylic and succinic acids, pyrrolidines and diphenolic acid, a potential replacement for bisphenol A used in the manufacture of polycarbonate resins.

Even more useful than levulinic acid itself are itself are levulinic ester ketals, novel compounds formed from the reaction of a levulinic ester (LAE) with an alcohol, typically glycerol, to form the ketal chemical moiety (see Figure). Levulinic ester ketals show broad solvency and compatibility; a range of possible chemical functionalities for producing a variety of adaptable chemical products using conventional chemical conversions; and thermal stability. Research has also shown that these compounds demonstrate exceptional hydrolytic stability across a broad pH range, which is key to their performance.

Levulinic ester ketals are the proprietary technology of US biomaterials company Segetis, founded in late 2006 by Sergey Selifonov – the inventor of Segetis technology – and Olga Selifonova and funded with a $15m investment by Khosla Ventures in January 2007. At Segetis, we believe levulinic ester ketal technology will result in a broad bio-based chemical product portfolio that will replace petrochemicals in a range of application areas. Currently, the main applications under development are plasticisers, solvents, thermoplastics, and polyurethanes for bedding, insulation, and coatings.

A life-cycle-analysis of our technology shows that each commercial sized ketal facility, when selling at capacity and substituting petro-based materials, has the potential to reduce US gasoline consumption by 35m gallons, and that it could avoid emissions of 425m kg of CO2-equivalents, every year. We have calculated the life cycle of our products when compared with fossil fuel based alternatives. The basic calculation is in terms of reduced fossil fuel use and reduced greenhouse gas emissions. The US EPA has an online database at http://www.epa.gov/ cleanenergy/energy-resources/calculator.html, which allows the conversion of fossil fuel use (FFU) and greenhouse gas emissions to an equivalent value of common metrics, such as miles driven, trees grown, homes electrified, etc.

The Segetis approach

It is worth noting that petrochemical products with similar characteristics of solvency and chemical functionality, particularly ethylene oxide and propylene oxide derivatives, require significant energy input in order to add oxygen atoms to the starting raw material. By contrast, the oxygen in our levulinic ketal esters is a result of the natural oxygen content of cellulose or sugar in a plant, and thus the chemical energy required to form the molecule is derived from plant photosynthesis.

In February 2009, Segetis announced that its semi-works production facility, based in Golden Valley, Minnesota, US, was fully operational and producing levulinic ketals suitable for development and further commercialisation. At full capacity, the facility will produce up to 100 metric tons/year of chemicals and chemical building blocks sourced from rapidly renewable resources.

‘The successful start up of our semi-works facility enables us to now move quickly into targeted, larger scale trials for products like solvents, polyols and plasticisers,’ stated Atul Thakrar, Segetis president and ceo.

The Segetis team scaled up the Segetis monomer technology from 1 L flasks in the laboratory to the semi-works facility in less than two years. And because the manufacturing facility does not require fermentation, the capital costs are below those of competing bio-platforms and improve our speed to market.

Levulinic ketal monomers can be formulated into end products with customers’ existing capital equipment and processes, making it a seamless transition from fossil fuel based chemicals. As an example, Segetis plasticisers can be drop-in replacements for current phthalate incumbents. In doing so, end users can leverage current capital equipment and logistics infrastructure while directly addressing regulatory needs and consumer demand for environmentally friendlier products.

The fossil fuel-based chemicals industry in the US and Western Europe has suffered significant setbacks in recent years, with the loss both of jobs and sales when domestic and foreign firms shifted production to Asia and the Middle East. Full-scale commercialisation of Segetis technology could reenergise the chemical industry and create jobs at multiple points in the value chain. By harnessing the power and reliability of biomass inputs for conversion into levelunic ester ketals, Segetis’ growth would also lead to a reduction in imported energy for the production of chemicals and polymers.

Snehal Desai is business vice president at Segetis based in Golden Valley, Minnesota, US.

Reference

1. F. W. Lichtenthaler in Biorefineries, Industrial processes and products, B. Kamm, P. R. Gruber, M. Kamm, (eds.), vol. 2, pp. 3-59. Wiley-VCH, Weinheim, Germany, 2006.

Plasticiser case study

Novel plasticiser structures based on levulinic ester ketals offer unique and game-changing advantages against conventional petroleum based phthalate esters. Currently, phthalates are being regulated out of sensitive market segments such as toys, food packaging and medical devices, and are on the EU ‘blacklist’ of restricted chemicals. The issue with phthalates is not only their inherent toxicity – they have been identified as reproductive toxins and endocrine disruptors – but also the potential for exposure created by their migration out of the polymer matrix. Since phthalates migrate, they are frequently absorbed or volatilised, increasing the risks of exposure to humans and the environment. Some bio-based alternatives exist, including esters of citric acid, however, these plasticisers have not been widely adopted, due to significantly higher migration compared with phthalates, as well as processing issues.

Segetis’ core plasticiser technology is 100% renewable carbon based. The ketal esters provide excellent plasticiser performance, as well as durability in the polymer matrix. We have shown that our ketal ester technology does not migrate out of the products, minimising environmental exposures. Additionally, Segetis plasticisers are excellent processing aids, allowing the polymers to be processed at much lower temperatures for shorter times, thus reducing the energy consumption and carbon footprint by manufacturers. Our research has shown that Segetis’ ketal ester plasticisers demonstrate the necessary technical properties, such as low migration and high efficiency, to offer a viable replacement for phthalate plasticisers such as BBP, DIDP and DOP, high volume materials used in applications from flooring to medical devices.