Remarkably, enzymes specifically designed by nature for a particular physiological purpose can be used in industrial applications under comparatively harsh conditions and are active on non-natural substrates. However, enzyme activity and stability in such processes does not always comply with what chemical engineers want. Consequently there is a growing demand to identify or generate better enzymes with new and unique properties that perfectly match the specific process requirements.

With high throughput screening techniques, it is possible to mimic evolution by screening billions of artificially created enzyme variants. In 1988, it was shown for the first time that the site-directed mutagenesis of an enzyme leads to an enhanced thermal stability of the enzyme. Plenty of examples have been published in the meantime. The major requirement for this was a deeper scientific understanding as achieved by several scientific milestones, for example, how DNA (genotype) and enzymes (phenotype) are linked and how the latter can be modified and produced in larger amounts if needed for technical applications. Nowadays, the molecular tools for engineering customised enzymes with novel features are well established.

The enzyme variants are created by mutagenesis and produced in expression hosts – usually microorganisms, such as bacteria or yeasts – in sufficient amounts to allow for the detection of the desired activity under specified reaction conditions. In this way, the best variants with the desired properties are identified. Sometimes, more than one round of mutation and screening is needed to come up in the desired properties; the best variants from the first round are subjected to one or more rounds of enzyme engineering until the enzyme’s characteristics comply with the specified criteria. Usually the combination of different beneficial synergistic mutations is necessary to reach the specified targets.

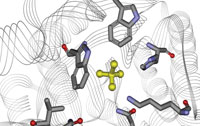

In the course of directed evolution, profound changes of the enzyme properties can be observed, but the drawback always is that a high number of variants must be screened, compared with the so-called rational design. In contrast to directed evolution, rational design demands a very deep understanding of the catalytic mechanism, as well as additional information on protein structure and functionality. Due to this high complexity, computational techniques are required to visualise the protein structure and its active site. Amino acid residues can be identified that are important for the docking of the substrate molecule to the active site or for the overall protein stability and site-directed mutagenesis at these sites is a straightforward way to manipulate enzyme performance.

The major advantage over directed evolution is the reduced number of variants that have to be screened, which is less costly and technically demanding. The major limitation is that structural information is not available for all enzymes and, even where this is available, not all effects of a mutation can be predicted.

Both strategies, directed evolution and rational design, represent state-of-the-art techniques in enzyme engineering. c-LEcta’s researchers often apply both methods simultaneously depending on the quality and quantity of information available about the target enzyme and the engineering objective itself. The guide on page 23 summarises the steps in enzyme engineering. Screening efficiency and speed are the decisive factors for the success of enzyme engineering, requiring highthroughput- screening (HTS) technologies.

Most widely used are fully automated robotic systems that analyse single enzyme variants. The major drawback of these systems is their high cost and low flexibility, although they were previously considered indispensable as it was believed that only by screening individual samples was it possible to identify improved enzyme variants. It was assumed that the coupling of genotype (the encoding gene) and phenotype (the enzyme) is a condition sine qua non.

C-LEcta's proprietary Cluster-Screening breaks with this dogma. By the concomitant analysis of thousands to hundreds of thousands of enzyme variants at once and a subsequent stepwise singling regime it is possible to correlate identified enzymatic activities in positive clusters with corresponding genotypes – without the need for expensive automated robotic systems. Over the years Cluster-Screening has proved to be a robust and highly flexible technique, often yielding better track records in much shortened development times and at significantly lower costs. This proprietary technology gives c-LEcta an important competitive edge, which is passed on to our customers.

Though enzymes are perfectly adjusted to their physiological task, their use in technical processes is often constrained by their stability and activity. If, for example, enzyme engineering yields an activity enhancement by a factor of three and if the thermal stability is likewise improved, it will have a drastic impact on the process economy. This is the most obvious advantage that can be gained from making tailored enzymes and gives companies a competitive edge. At the same time, the enzyme variant may represent a new unique biocatalyst that can be protected by a patent.

The improvement of enzyme performance through enzyme engineering varies considerably. For instance, it may enable the use of non-natural substrates that were not addressed at all prior to the engineering. At c-LEcta, for example, we have achieved an improvement of the enzyme’s thermal stability or temperature activity profile in the order of 10°C or more in many projects. However, what is possible by engineering also depends on the starting point, for example, if the enzyme to be tailored is commercially available or discovered in nature.

The implementation of a biocatalytic process requires highly efficient enzyme catalysts. Sometimes the direct use of a commercial enzyme will result in a satisfying performance, but a good process economy is less likely to be obtained as the number of enzymes that can be purchased from a catalogue is limited. Prospects are drastically improved if companies like c-LEcta start to screen their comprehensive enzyme collections for the best-suited enzyme.

However, sometimes entirely new and unique enzyme catalysts are needed, either necessitated by the target reaction or because of a limited freedom to operate on available enzymes. In that case, c-LEcta will tap the natural biodiversity by so-called genome and metagenome screenings. In both cases the genetic information is available in ready-to-screen formats and immediately inspected for the desired enzyme activity. Our genome libraries are obtained by pooling the genetic information of various microorganisms, whereas the metagenome libraries are obtained by the direct isolation and cloning of DNA from environmental samples.

Many microorganisms present in certain environmental habitats cannot be cultured under lab conditions. This hurdle is overcome if the genomes of all microorganisms in the habitat are ’unified‘ as a metagenome. c-LEcta has created many metagenome libraries; for some of those libraries, the samples were taken from contaminated sites. If a habitat is contaminated with a certain compound class, the prospects to isolate enzymes acting on such compounds are enhanced. As soon as c-LEcta has discovered an enzyme from biodiversity suitable for the target application, the respective enzyme will be thoroughly analysed to identify respective bottlenecks and to define the space for optimisation by enzyme engineering. But, of course, a well established biocatalyst can serve as starting point for enzyme engineering.

Typically industry partners approach c-LEcta with a target reaction, for example, the synthesis of an intermediate in the production of an active pharmaceutical ingredient (API). The technological and economic feasibility of the aimed reaction is evaluated. If this can be answered in the affirmative, enzyme collection as well as (meta) genomic libraries are screened for the desired enzyme activity. Upon the identification of suitable enzyme candidates, they are optimised by engineering for the target application.

Enzyme engineering gives companies the competitive edge and the chance to strengthen their patent portfolio. Most of c-LEcta’s projects have been done in close collaboration with partners from the pharmaceutical or specialty industry and more than five customised enzymes have been successfully implemented into industrial scale. Those enzymes are produced in multi-kg to ton quantities and supplied to the respective industry partners. Furthermore, c-LEcta has developed a new asparaginase enzyme for pretreating foods to lower acrylamide in foods like coffee, chips and baked goods (C&I 2010, 22, 12). Another example is a newly developed class of detergent enzyme for removing grass stains. As the scope for natural evolution is not limited, so the scope for protein design is unlimited. A steadily growing, in-depth understanding about protein folding and structure–activity relationships, together with growing capabilities in computational chemistry, give reason to believe that the realm of protein engineering has just started and we are still at the very beginning of an ongoing revolution.

A five-step guide to enzyme engineering

1. Selection of the starting enzyme: Commercial enzymes, as well as enzymes selected from an enzyme collection or (meta)genomic libraries, can serve as starting point.

2. Definition of the sequence space for mutation: The amino acid sequence of the enzyme must be known. At the DNA level, random mutations in specified areas of the sequence will lead to the exchange of amino acids with corresponding changes of enzyme properties. If the structure is known or if a homology model can be computed, the amino acids can be selected purposefully in a target oriented manner.

3. Enzyme production in suitable host organisms: The enzyme encoding gene must be cloned into a so-called expression vector to allow production of the active enzyme in a suitable expression host, such as bacteria or yeast. The transformation of the bacterial host with the expression vector leads to formation of a clone in which one enzyme variant is expressed. Thousands to hundreds of thousands clones form the enzyme library.

4. Assaying activity: A specific analysis of enzymatic activity with a low signal-to-noise ratio is required to identify changes in biocatalyst properties. In high-throughput screenings, spectrophotometric assays are preferable. The underlying principle is based on chromogenic or fluorogenic substrates that are formed or depleted by the enzyme reaction. Also, staining the product or its detection by subsequent reactions as well as indicator dyes – for example, if the reaction is accompanied by a pH-change – are used. The Cluster-Screening of c-LEcta also allows for high-throughput screenings of enzyme libraries based on HPLC or gas chromatography.

5. Screening and selection of the best variants: Highly effective and selective systems are needed to assay the biocatalytic activity from 104 to 107 individual variants of complex enzyme libraries simultaneously, requiring expensive fully automated robotic systems or smart technologies like c LEcta’s proprietary Cluster-Screening. Once an improved variant is selected it can be subjected iteratively to another engineering round. In so-called recombination libraries the beneficial effects of different mutations can be combined and, depending on the engineering objectives, c-LEcta is able to provide a significantly improved enzyme variant within a few months.

Andreas Buthe is business development manager at biotech company c-LEcta based in Leipzig, Germany.