There is a new mandate in consumer product R&D. While organisations have continued to invest in research, the cost to create and test new products, particularly via consumer panels, has risen relentlessly. Simultaneously, staffing levels have flatlined or even decreased, putting additional pressure on R&D groups. Organisations now expect every scientist they employ to work better, faster, and smarter: to do more with less.

In a resource-stretched environment, achieving innovation – that perennial R&D buzzword – requires organisations to rethink the way they approach scientific questions and conduct product development. Can scientists see outside the boxes set by current technologies or standard methods for meeting consumer expectations? Innovating by merely making small changes faster will not achieve the breakthroughs that excite consumers, set a company apart in the marketplace or drive revenue growth. To do more with less, effectively and efficiently, consumer product companies must strive for innovation productivity.

Recently, tools and technologies developed to automate experiments in life-science research laboratories have been adapted to reduce the time and cost associated with testing and developing consumer products. High throughput research (HTR) employs microscale testing that allows scientists to conduct rapid, low-cost, low-risk ‘screens’ of a wide range of variables. These screens do not replace consumer testing and other traditional product development approaches; rather, they augment these critical processes by providing a way to explore more fully the experimental space surrounding a research problem. With cycle times measured in weeks rather than months, HTR enables researchers to produce product relevant information on a much larger sample set – information that organisations can then use to more intelligently and confidently select samples for traditional performance and consumer testing.

A new approach

Even through the global economic crisis beginning in 2008, organisations have continued to invest in R&D. The annual trends forecast compiled by the Industrial Research Institute (IRI) in 2009 helps explain why.1 Anticipated R&D spending flattened in 2009, capping four years of increased investment. Capital spending has generally decreased since 2002, yet even in 2009, the year survey respondents finally projected decreases in R&D spending, respondents still expected to increase their support for new-project R&D.

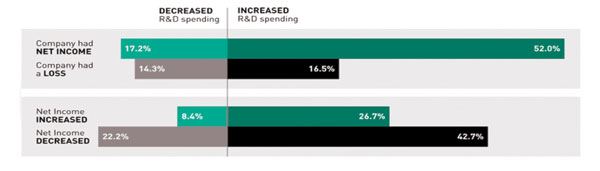

Put simply, companies are seeking innovation. Data by Booz & Company indicate that Global Innovation 1000 companies continue to increase their R&D budgets even when facing corporate losses or falling net incomes (Figure 1).2 The authors of this survey concluded that for these companies, ‘a reduction in innovation efforts would be akin to unilateral disarmament in wartime’. Additionally, a report on a symposium organised by H.B. Fuller in September 2010 for 50 packaging converters described consumer packaged goods companies as ‘hungry for innovation,’ and noted that ‘converters that deliver innovation and new capabilities will win their business’.3

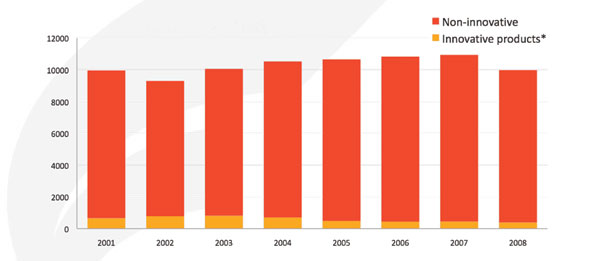

Consumer products companies have little to show for their investment and hunger, however. Data compiled online by ProductScan on new consumer product releases since 2001 reveal that only about 3% of new products offer significant new or added benefits to consumers (Figure 2).4 Not surprisingly, organisations are frustrated. In the IRI trends forecast, respondents cited ‘growing the business through innovation’ and ‘accelerating innovation’ as the biggest challenges facing technology leaders in 2008, with one third of respondents ranking the former in the top position.5

HTR represents a new approach to consumer product R&D, one that supports the creation of truly innovative products by empowering and informing the traditional product development process. HTR does more than enable the rapid creation of new formulations; it also provides a way to screen these formulations in a high throughput cycle that mimics and feeds well-tested samples into the traditional product development process (Figure 3). While the existing product development cycle can take months to complete, the HTR-powered cycle produces much more data in a fraction of the time – often in the order of days. By rapidly testing a much larger range of variables within the experimental space, scientists can uncover unexpected outcomes or research directions and link testable, quantitative parameters to consumer preferences. The ability to test and refine these parameters early and against a much broader sample set lets organisations ensure that they are advancing more viable candidates into full-scale formulation and consumer testing.

Consumer product R&D

Applying the HTR techniques and methods initially pioneered in the life science and chemical industries for lab automation to formulation and characterisation in the consumer products industry has required significant advances in the technology. Before 2000, no single platform could even dose both solid and liquid materials, which prevented scientists from preparing realistic formulations. Thanks to advances in the last decade, all of the key steps in consumer products R&D – gravimetric dispense of solid, liquid, and viscous ingredients, high shear mixing for emulsification, and temperature and other process control features – can now be carried out using automation. Several companies have contributed to this effort including hteAG, Chemspeed, Zinnser Analytic and Freeslate. Additionally, Freeslate has pioneered the use of additional tools for rapid physicochemical characterisation and performance testing on consumer-relevant substrates, such as hair, fabric and hard surfaces. These additional tools enable not only high throughput formulation but also application testing against product stability, stain release, softness, colouring, conditioning, coating and many other protocols, supporting faster development of novel products.

Second, HTR systems must integrate effectively across the entire research cycle. Traditionally, companies have initially focused on one aspect of the research cycle, such as formulation. Organisations fail to realise the value of their investment and accelerate product development, however, if they are unable to rapidly evaluate the formulations they have created. Take stability testing, which is a critical bottleneck in R&D for both consumer products companies and their suppliers. While time consuming and labour intensive, stability testing is essential to ensure that new products perform as consumers expect.

The third challenge to making HTR relevant for consumer product R&D is finding ways to use the data generated to build effective, predictive models for consumer response. The consumer rules the marketplace, but correlating subjective consumer preferences to objective, experimental parameters takes time and can be expensive with traditional R&D approaches. HTR offers the opportunity for organisations to rapidly translate consumer preferences into low-risk, rapid screens that enable organisations to build large data sets of directional information before engaging in consumer panels. For scientists to capitalise on these data sets, however, organisations must be able to effectively manage collected data to build knowledge and understanding. Advances in HTR software, like Freeslate’s Lab Execution and Automation (LEA) software suite, provide simple experimental design and robust data management to maximise the value created with HTR workflows.

Working in tandem, traditional and HTR techniques create a feedback loop that can help organisations be more agile in responding to consumer demands. Today, HTR platforms offer sensing technology to measure key, fundamental properties, such as rheology, colour, gloss, friction, and wear resistance. They can handle diverse substrates, such as hair, fabric and hard, soft or flexible surfaces. Combining these capabilities in a modular fashion creates workflows for application tests from colour fastness or stain release to washing and conditioning, film formation, deposition and release, and stability.

For instance, Freeslate has developed an HTR system to formulate products for hair treatment. The protocol created a range of formulations according to input parameters, applied the product to real hair, washed the hair, and measured mechanical properties correlated to consumer perception of hair ‘softness.’ A microscale protocol replaced manual and labour intensive methods and enabled 10 times more experiments to be obtained from a standard length of hair. Further, total throughput also increased 10-fold, allowing scientists to test a much wider and more representative experimental space. In another example of the successful application of HTR to consumer products R&D, Freeslate helped a customer develop an HTR protocol that linked quantitative tests to various consumer responses about the sensory ‘feel’ of personal cleaning products. The company used three HTR tests that modeled ‘virtual consumers’ based on an algorithm the company developed. With the automated protocol, the company was able to conduct over 1000 experiments in six months. When the company later tested the product among real consumers, it was able to use the information generated in the HTR studies to rapidly bring a successful new product to market. The HTR protocol significantly shortened the product development timeline and generated a data set that could be mined to create future products.

Tailored product development

Applying HTR to traditional consumer product R&D provides more information and a better understanding of new materials and formulations. These datasets in turn can be exploited in data models correlated to consumer preferences. Rather than working in a limited experimental space, scientists can begin to make predictions or locate desired product attributes within the entire space of experimental parameters. More importantly, they can rapidly test potential products virtually before conducting expensive consumer panels. HTR-powered R&D enables the dramatic gains in R&D productivity and innovation that will help consumer products companies truly do more with less.

John S. Senaldi is president and ceo of Freeslate, based in Sunnyvale, California, US.

References

1. R. Cosner, R&D Trends Forecast for 2009, Industrial Research Institute, January-February 2009, 19-21.

2. B. Jeruzelski and K. Dehoff, ‘Profits down, spending steady: The global innovation 1000,’ Strategy + Business, 27 October 2009.

3. S. Sterling, ‘CPG companies look for innovation,’ Packaging World Magazine, November 2010, p. 32.