The performance of brain implants and prosthetics could in future be improved with novel conducting polymers. Elisabeth Jeffries reports

Doctors treating people with severe epilepsy have difficulty detecting the site in the brain from which seizures originate. An implant trialled in laboratories could, however, allow them to continuously monitor and treat this electrical activity thanks to new coatings made from a conjugated polymer (CP), PEDOT and a polystyrenated sulfonate (PSS).

Electrode implants used clinically at present for this purpose, known as electrocorticography, consist of platinum and can be placed on the brain cortex for no more than four weeks. By contrast, the substitute, consisting of platinum coated with PEDOT:PSS, is more sensitive and has the potential to last over a year – reducing the need for invasive surgery and improving treatment for intractable epilepsy.

‘You need a long monitoring period to capture the location of the epileptic seizures in such patients. Identifying the small group of nerves generating the seizures helps cure the disease,’ says Maria Asplund, Group Leader at the BrainLinks-BrainTools Centre of Excellence at the University of Freiburg, Germany.

Following such investigations, many scientists draw attention to the potentially game-changing character of electrodes coated with PEDOT:PSS, not only in recording electrical activity more precisely but also in therapeutic organ and nerve stimulation. This is because of the unique properties of PEDOT:PSS. Already commercially available in the information technology sector, PEDOT is an organic macromolecule with a backbone chain of alternating double- and single-bonds and is insoluble – a characteristic shared with other CPs.

When produced with PSS, however, the composite exists comfortably in saltwater environments because the PSS atoms are in a hydrophilic charge group. Indeed, the material can absorb water as well as interface with molecules such as proteins in the human body. ‘It is one of the few known materials to have both ionic and electronic conductivity, which makes it an ideal candidate for biomedical applications,’ says Hyunwoo Yuk, a researcher at the department of mechanical engineering, Massachusetts Institute of Technology (MIT), US.

This factor, together with a large surface area afforded by the conjugation of PEDOT, makes the material a potential replacement for electrodes made of metals such as platinum or silver. Unlike many materials, it is relatively stable in human tissue and less likely to be rejected by the body.

[PEDOT:PSS] is one of the few known materials to have both ionic and electronic conductivity, which makes it an ideal candidate for biomedical applications.

Hyunwoo Yuk Department of Mechanical Engineering, Massachusetts Institute of Technology

The large surface area of the PEDOT molecules, compared with platinum, the metal of choice for many existing applications, offers particular advantages. ‘Due to this feature, electrodes coated with PEDOT have a higher capacitance, signifying that a larger amount of charge/voltage can be stored on the device. This enables smaller electrodes and allows more accurate diagnosis than platinum,’ explains Christopher Proctor, senior research fellow in the department of engineering at the University of Cambridge.

Studies show that in some cases the coating has 100 times greater capacitance than a platinum electrode of the same surface area. Since the electrodes are smaller and slimmer, scar tissue around the implant is reduced – offering a significant advantage over metal devices.

PEDOT: PSS is prepared by mixing an aqueous solution of polystyrenesulfonate (PSS) with the 3,4-ethylenedioxythiophene (EDOT) monomer. A solution of sodium persulfate and ferric sulfate is added to the mixture. The resulting material enhances conductivity and reduces electrical impedance, compared with a metal electrode. This means opposition to the electric current is lowered by several orders of magnitude once the coating is added, thus doubling battery life in some cases.

Hence, battery replacement is likely to be less frequent – clearly a step forward for applications requiring surgery. At present PEDOT:PSS coats the electrodes, but in the long term could make up the entire implant. ‘It is conductive enough to completely replace metal,’ says Proctor.

Much excitement has centred on the potential use of metallic devices coated with PEDOT:PSS, especially because they can be used in the human brain and nervous system. Some claim it represents a step forward in artificial intelligence by restoring function or enhanced abilities to humans through the integration of an artificial component. To meet that definition, the device would rely on feedback data from electrical signals to learn and make decisions.

However, current research shows such capacities for brain implants could be many decades, if not centuries, away. Like metals used at present, PEDOT:PSS electrodes allow a bidirectional interface between the device and human neurons, enabling stimulation and recording of brain activity. Where PEDOT:PSS makes immediate advances is in granularity of data, providing more information to doctors rather than replacing decision-making facilities.

‘Whereas platinum electrodes provide information about clusters of thousands of cells, PEDOT:PSS can get down to a single cell. This means it has the potential to greatly improve our understanding of how the brain works,’ explains Proctor.

However, no evidence yet exists that the coated electrodes can provide the same long-term performance as a metal such as platinum. This has been approved since the late 20th century for use as a deep brain stimulator (DBS) for severe epilepsy and Parkinson’s disease, for example. Platinum implants in the cochlea (inner ear) for deaf people; spinal cord stimulators; and pacemakers are now established.

It has good durability. ‘Some devices with platinum electrodes used internally have been implanted for ten years. Issues with corrosion and battery life vary between patients as well as different devices on the market,’ says Proctor. For DBS, the rechargeable battery of standard platinum electrode models lasts three to five years.

By contrast, the coated electrode tested in laboratories works for several months both in vivo and in vitro, according to Asplund. This is considered enough to view the basic implant as sound as far as durability and stability are concerned but needs more work.

Platinum electrodes have been approved since the late 20th century for use as a deep-brain stimulators for severe epilepsy and Parkinson’s disease.

Specific challenges

Despite the innate qualities of the material if used in the human body, scientists working on PEDOT:PSS need to show it can exceed metallic performance by overcoming particular challenges. The coated electrode has to function on two fronts – the interface with the human tissue and with the metal electrode.

Advances have been made in both, but improvements are required to guarantee long-term stability. This means it stays intact as a coating while also enduring the natural biochemical challenges in the longer term arising from its location in the body.

Among the problems being addressed is coating delamination on the metallic electrode. ‘The material itself is a good one but as a coating, it is prone to fragmentation, which is not ideal for long-term use,’ says Hyunwoo Yuk.

As one of several solutions that could resolve this problem, the team at MIT introduced a hydrophilic polymer adhesive layer – a polyurethane – with a thickness of a few nanometres. This formed a strong adhesion with the substrate – the platinum electrode – and an interpenetrating polymer network with the PEDOT:PSS. The hydrophilicity and subsequent swelling of the adhesive layer allow diffusion of the conducting polymer precursors throughout the adhesive layer.

‘The resultant conducting polymer achieves superior adhesion performance and remarkable mechanical and electrochemical stability without compromising the electrical or mechanical properties of the conducting polymers,’ says Hyunwoo Yuk. Another technique employed to reduce fragmentation of the CP coating is to add a surfactant, which smooths the surface of the coating.

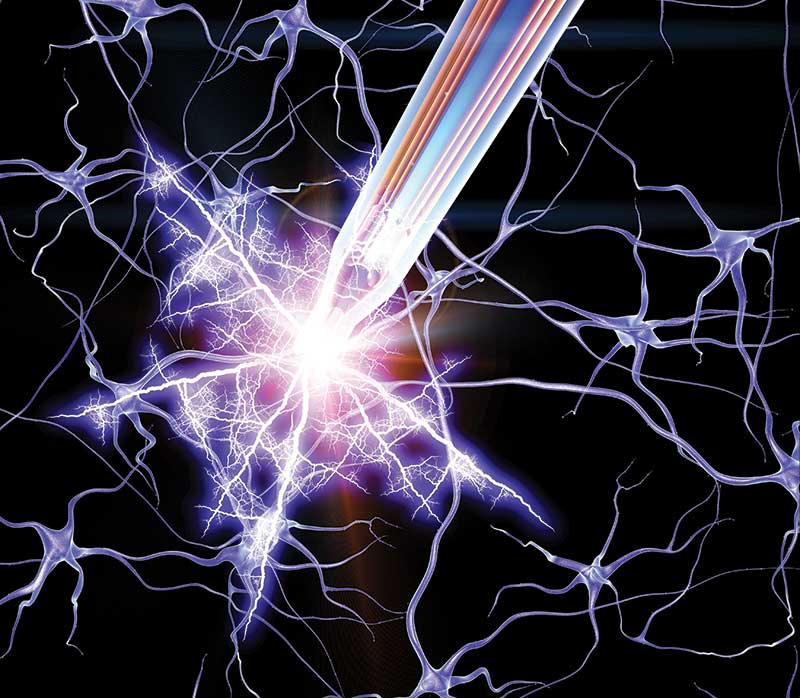

Image caption: Deep brain stimulation (DBS). This illustration shows an electrode sending electrical impulses to nerve cells.

Several techniques have been tried out to improve stability at the wet tissue interface. For instance, the MIT researchers developed an electrical bioadhesive interface based on a thin layer of a graphene nanocomposite. This allowed the device to be removed from wet tissues without causing further trauma while remaining robust.

The use of hydrogels – naturally occurring polymers – in connection with PEDOT:PSS also provides opportunities to improve the coating performance. PEDOT:PSS already has a character rather similar to hydrogels, but this can be further enhanced by growing PEDOT into a preformed hydrogel network.

Such trials have shown that PEDOT:PSS contributes conductivity and electrochemical stability to the hybrid. At the same time, the hydrogel contributes a softer mechanical character and increased porosity as well as facilitating further functions for the coating beyond its work as an electrical contact. These include drug release or the employment of a biomolecule to help cells attach to the surface of the coating.

Researchers are investigating optimal formulations to lengthen the lifetime of the electrode coated with PEDOT:PSS, while balancing stability requirements with high conductivity and high capacitance. When assessing different opportunities to achieve such aims, they consider a number of variables. ‘Some trade-offs exist with approaches reported to date. For instance, introducing a crosslinking agent for stability tends to decrease conductivity,’ explains Proctor.

Experiments to add functionality are also under way. Drug release, ‘stretchiness’ and biodegradability are all attractive features, as is its potential use in a composite.

Demand is clearly a key consideration in terms of where to focus research. In cochlear implants, the use of platinum electrodes is already satisfactory, though a PEDOT:PSS coating would help by reducing frequency of battery recharge.

The first approval for a PEDOT-based coating by the US Food and Drug Administration occurred in 2016 for a cardiac catheter.

Prosthetics potential

One area for development is the use of electrodes with prostheses – hailed as a potential advance in artificial intelligence. In reality, research for artificial limbs has concentrated on the direct stimulation of sensory pathways from the outside environment to the nervous system, helping amputees feel more and possibly use their nervous system to control the prosthesis themselves, which is not the same as artificial intelligence. ‘The material can be used to record electrical activity and stimulate neurons, but computational facilities, in which the device instructs when to stimulate, is much further out,’ says Proctor.

At present, stimulation techniques available to amputees are not precise or direct enough to allow a direct interface with external conditions. Electrodes coated with PEDOT:PSS would make a profound difference to overall motor control. However, other materials, such as platinum-iridium, iridium oxide, carbon nanotubes and hydrogels are also under investigation. If successful, replacing the inputs through direct electrical stimulation would alter the way patients are treated and prostheses are designed.

Asplund sees potential for PEDOT:PSS in this application. ‘I personally see more room here, since there is not yet a functional solution on the market. If someone were to really invest in such a device – with intraneural electrodes – I could imagine it could be commercially developed within three to five years.’

That note of caution alludes to a well-documented barrier. Regulators are likely to delay the development of PEDOT:PSS as an entire electrode for decades, despite its major advantage as a smaller, more sensitive and less invasive device. This is because they are reluctant to accept completely new materials in the human system. Any alterations to an approved device, which might influence the properties of the final product, also demand a re-evaluation of the entire device. Moreover, accelerated testing, which simulates the lifespan of the device over decades to prove its durability, is complex.

Despite these obstacles, a niche has been carved out that could be further broadened. The first approval for a PEDOT-based coating by the US Food and Drug Administration occurred in 2016 – for acute and therefore short-term use. Amplicoat was a component of an invasive CE-marked medical device, approved for a cardiac catheter. Produced by Biotectix, now part of German company Heraeus, in collaboration with US company Acutus Medical, the coating can be applied to metal electrodes for numerous medical devices including neurostimulation, cardiac pacing, electrophysiology recordings, cochlear implants and gastrointestinal recording and stimulation.

Scientists hope more devices will appear on the market in future. Proctor envisages a medium-term horizon for an electrode for epileptics, which would be coated with PEDOT:PSS and capable of drug release. ‘It may be commercially available within five to ten years,’ he says.