Anthony King

Scientists at the University of Sydney, Australia, report they have biodegraded polypropylene with the help of fungi.

Polypropylene is a ubiquitous plastic, with 68m t made in 2015. Yet only around 1-2% of it is recycled. The researchers searched the literature for fungal species that would be safe and potentially useful in breaking down the polymer.

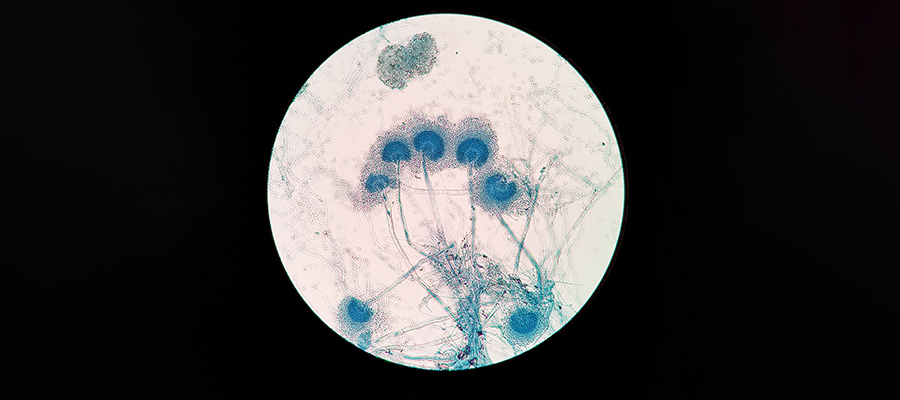

‘We were surprised that we were able to generate some of the very highest degradation rates that we are aware of for a single culture of fungus,’ says Ali Abbas, a chemical engineer at the University of Sydney, who led the research. The lab chose two species, Aspergillus terreus and Engyodontium album, typically found in soil and plants.

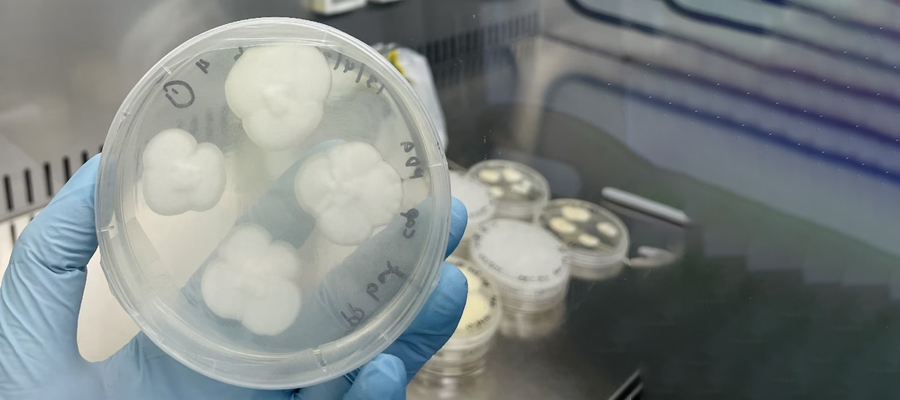

Engyodontium album was able to break down polypropylene after it had been pre-treated with either UV light or heat. Image: Amira Samat

First, the polypropylene was pre-treated with UV light, heat or a chemical treatment. Polypropylene as a metallised film lost 25% of its weight when pre-treated with UV light and then placed with the E. album species, and 22% when it was heated treated and then placed with the fungus.

Aside from metallised film, the Australian lab also experimented with polypropylene granules and films. Again, pretreatment steps were necessary to facilitate the fungus in attacking the surfaces of the granules and films. The resulting polymer samples were then incubated with one of the fungal species for 90 days.

Engyodontium album is a ubiquitous fungus commonly found in soil and plant debris.

Residues were tested with various analytical techniques such as gas chromatography-mass spectrometry; scanning electron microscopy; and Fourier transform infrared spectroscopy. Findings suggested that lower carbon chain chemicals were produced from the polymer structure of (C3H6)n, says Abbas.

‘From what we understand from the literature, the fungi are releasing enzymes that are actively degrading the plastic surface,’ he says. ‘I would imagine there’s also some chemical reactions happening as well, but we don’t know exactly.’ This will be the subject of follow-up research.

Ipsita Roy, a biomaterials expert at the University of Sheffield, UK, describes the paper as interesting but expresses some concerns. ‘There is loss of weight and surface degradation. Great. But you want to get a final product that can be recycled and to avoid generating microplastics,’ she says.

‘Perhaps the reaction can be optimised in order to get monomers, which can then be used for other purposes,’ Roy suggests.

Proud to represent the @UKSBiomaterials at @ESB_2022 supporting colleague, and one of my amazing mentors, Professor Ipsita Roy @ipsita2015 highlighting the importance of sustainable polymers, PHAs, in biomedical applications @msesheffield pic.twitter.com/8GAKkq100K

— Dr Caroline S. Taylor (@C_S_Taylor88) September 8, 2022

Nonetheless, she advocates a move away from fossil-based polymers and has recently spoken to UK policymakers in parliament about the need to switch to more sustainable polymers. ‘There are bio-based polymers which have properties like polypropylene,’ says Roy, such as poly-hydroxyalkanoates, or PHAs, which can be generated via fermentation.

Such biopolymers do not currently have the advantages of the scale of manufacture that existing polymers hold and are relatively more expensive. ‘Governments need to subsidise the production of these sustainable polymers,’ says Roy.

The Sydney lab recently also isolated two fungal species from the surface of polypropylene floating in the marine environment on marine plastic debris; the lab is now working on those to ascertain their degradation rates.