‘We get similar results but use sugar structures, which are ubiquitous in nature and generally completely non-toxic, to provide rigidity and performance properties.’

Researchers from the École Polytechnique Fédérale de Lausanne (EPFL), in Switzerland, have developed a novel method for producing polyamides using sugar derived from agricultural waste.

Publishing their work in Nature Sustainability, the researchers share the development of a catalyst-free process to convert dimethyl glyoxylate xylose – a carbohydrate made from biomass such as wood or corn cobs – into polyamides. The process is said to be 97% efficient, making a significant impact on waste reduction.

Tensile and thermal property testing showed that the new bio-based polyamides could compete with fossil-based counterparts. Also, looking at the mechanical recycling of the polymer the researchers found that through three cycles of this processing tensile properties remained nearly identical. In addition, chemical recycling required what the researchers described as ‘remarkably mild conditions’.

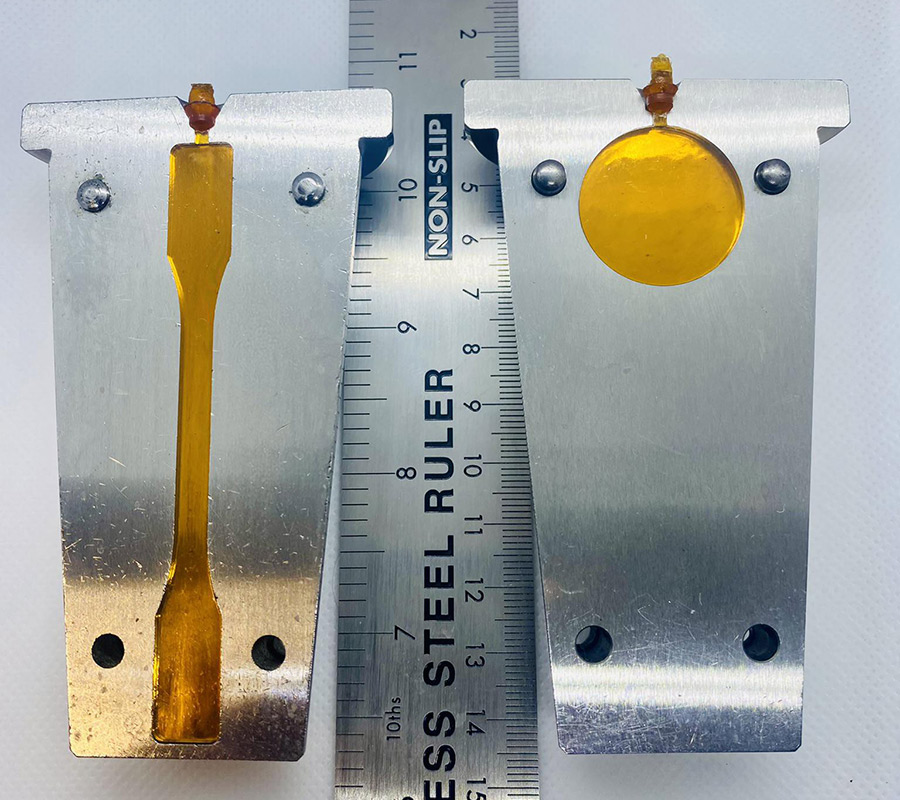

The polyamide material in the mould after injection moulding. © 2024 EPFL

A techno-economic analysis for the production of the new polymer as pellets indicated that the minimum selling price of the polymer was within the 2022 market price range for nylon-66, and well below the market price for unreinforced high-performance polyphthalamides. The researchers say that the new polymer could be used in a range of applications including automotive parts and consumer goods, significantly reducing their carbon footprint.

Professor Jeremy Luterbacher, EPFL, who led the research team commented, ‘Typical fossil-based plastics need aromatic groups to give rigidity to their plastics – this gives them their performance properties like hardness, strength, and high temperature resistance. Here we get similar results but use a sugar structure, which is ubiquitous in nature and generally completely non-toxic, to provide rigidity and performance properties.’

Last year a consortium, which includes Neste, announced the development and use of a bio-based construction material which the partners say serves as ‘temporary carbon storage’.