In the second part of our chat with Bright SCIdea finalist Team Eolic Wall, we found out how they prepared for their presentation and judges’ questions, and what’s next for their innovative wind turbine technology.

The road from Eureka moment to finished product is paved with peril. Team Eolic Wall’s idea for small, modular wind turbines that use magnetic levitation to harness more power than existing turbines could bring wind power generation into our very homes. But bringing a groundbreaking product to market is not just about mastering the science. It must make business sense too.

As with the other Bright SCIdea hopefuls, Team Eolic Wall received free training from SCI in the form of online tutorials from experienced professionals including modules on structuring a business, financial modelling, branding, and marketing.

After completing the training, Eolic Wall rose to meet the challenge. The team qualified for the Bright SCIdea final and, with it, the pivotal presentation in front of a live audience and panel of expert judges.

Many of us take it as a given that we speak to people at work in our native tongue. The nuances of communication – the cultural subtleties and oddities of the English language – aren’t a concern. But Team Eolic Wall had to present in their second language.

Pitch perfect?

‘This was not our first international presentation, but it was the first one in a foreign language,’ said Alfredo Calle, Eolic Wall founder, ‘so that's always a little bit intimidating until one gets used to it.’

The key to them nailing the pitch was in the spade-work. Calle and his colleagues rehearsed the speech until they knew it by heart. ‘It’s all about training and preparation,’ he said. ‘The more you rehearse, the more confident you feel when the presentation moment comes.’

Of course, the presentation is predictable but the judges’ questions are less so. Having undergone the rigours of competition, Calle recommends that this year’s entrants prepare by trying to predict the types of questions they will be asked. A cold rehearsal could help with the potentially stunning situation of someone throwing questions at you from strange angles.

That team Eolic Wall presented its technology online made theirs even trickier still, especially given a technical hitch at the beginning. But they had polished the presentation to a smoothness that offset such difficulties and came away as joint winners of the Audience Award.

The only lingering regret for them was that Covid prevented them from coming to London. ‘We wish we could have made it to the final,’ he said. ‘Facing the judges and audience live would have been a tremendously valuable and enriching experience.’

A wind energy democracy

Since the Bright SCIdea final, the Eolic Wall is being built brick by brick. The team has received three grants in recent months including one from ProCiencia, the largest innovation agency of the Peruvian government.

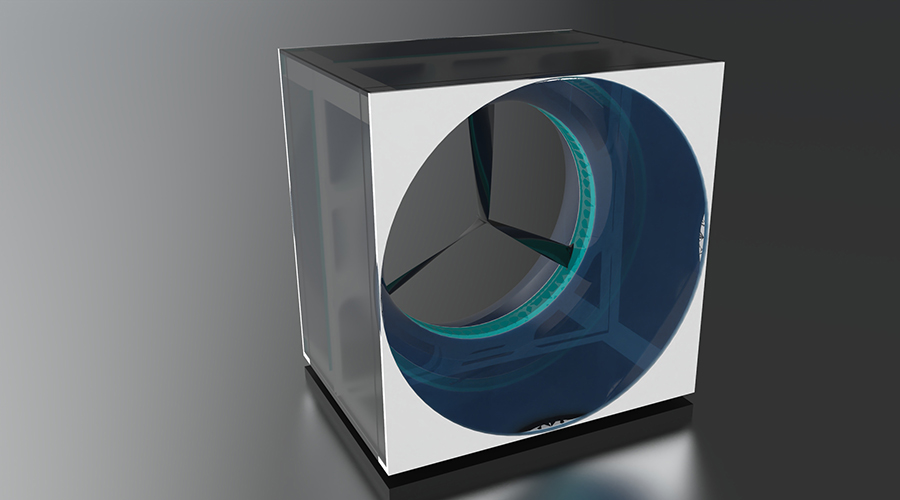

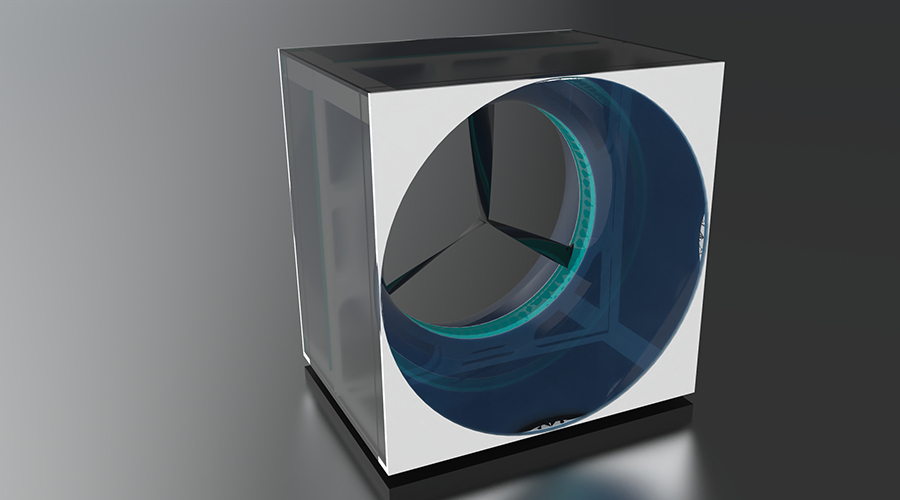

Eolic Wall's wall-mounted wind turbine is designed to power homes and offices in situ.

However, perhaps the most exciting development is the technology itself. ‘We have accomplished a peripherally supported wind turbine that works with magnetic levitation,’ Calle said. ‘That's a huge milestone that makes us believe we are building something big.’

Calle hopes for more investment to develop the technology further. At heart, he believes the Eolic Wall will give regular people the chance to generate affordable wind energy from home.

‘We are working out a solution to democratise wind energy for the sake of this blue rock we call home.’

>> Find out how Team Eolic Wall’s innovative technology in part 1 of this blog.

Imagine owning a small wind turbine that generates all of your home’s energy needs. As the clock counts down on entries for for the 2023 Bright SCIdea Challenge, we caught up with Team Eolic Wall, the Audience Winner for the 2022 competition.

Eolic Wall was always a nice fit for Bright SCIdea. The team spotted a problem in our renewable energy mix and came up with a scientific business idea to solve it. They saw that wind energy is generated for the public, but it isn’t generated by the public. This stands in bright contrast to solar power generation.

‘Today, 40% of all installed capacity in solar energy is based on solar panels installed on the rooftops of home and corporate buildings,’ said Alfredo Calle, founder of Eolic Wall. ‘The remaining 60% correspond to solar farms.’

Eolic Wall's wall-mounted wind turbine is designed to power homes and offices in situ.

The wind industry is different. ‘Only 1% of the installed capacity comes from households and businesses,’ he added. ‘That is, 99% of all installed capacity in the world comes from wind farms. That sort of concentration is a problem that hampers the energy transition.’

Calle believes this disparity hampers the move from fossil fuel dependency to clean, renewable energy. For many, micro-generation is key. We need to put power – renewable power – in the hands of the people. His idea is to make wind energy available in the home, just as solar exists on roofs everywhere.

The scale of this task is daunting. It turns out there’s a reason why we don’t all have wind turbines bolted onto our homes. The problem, Calle argues, is that a windmill must be large to be efficient.

He believes the Eolic Wall could change that – that this wall-mounted wind turbine is efficient enough to power our homes and offices.

‘We have created a technology that not only doubles wind speed to harvest more power from the same wind resources, but also has a wind turbine that works with magnetic levitation to almost eliminate any friction.’

From applicant to finalist

So, how did a team based out of the National University of Engineering in Peru and Universidade Estadual Paulista in Brazil end up competing for the £5,000 first prize in the Bright SCIdea final?

Chance. Fortune. Happenstance. Calle and his colleagues came upon Bright SCIdea through a social media post that immediately captured their attention.

‘We thought that the Eolic Wall was ideal for Bright SCIdea because of the huge positive impact that this technology could have,’ he said, ‘and also because it perfectly fit into Bright SCIdea’s thesis of supporting ideas in the intersection of business, innovation and science.’

Applying was simple, although the business plan submission was intimidating at first. However, like all BrightSCIdea applicants they received coaching, and their brainchild found form.

‘The key driver to overcome that challenge was not to miss any training sessions and tutorials,’ Calle said. ‘The good news is that after going through the whole process you feel that everything was worthwhile. No pain, no gain.’

Check out fellow 2022 finalist Klara Hatinova from Team Happy BioPatch in conversation with the Periodic Fable podcast.

Have we underestimated the eco-anxiety middle-aged and older people feel? According to a recent survey, younger folks aren’t the only ones frowning at the horizon. Eoin Redahan writes.

When you think of a middle-aged person suffering from exo-anxiety, what do you imagine? Is it a grey-haired woman gazing from a mountain peak with a single, heroic tear staining her cheek? Is it an auld fella rending his garments and shaking his fist at the sun?

I mean, possibly, but the reality is probably less dramatic. It could be the Pakistani householder who wonders if her family home will be swept away in the next flood. It might be the 39-year-old Australian who wonders if his country will be habitable when his young child grows up.

It might be the Maldivian who wonders if his homeland will go the way of Atlantis within 20 years. It was me when someone decided it would be a good idea to have a barbecue in the fields beside my house in the middle of the heatwave – when the grass was as dry as straw and wildfires scorched in south London.

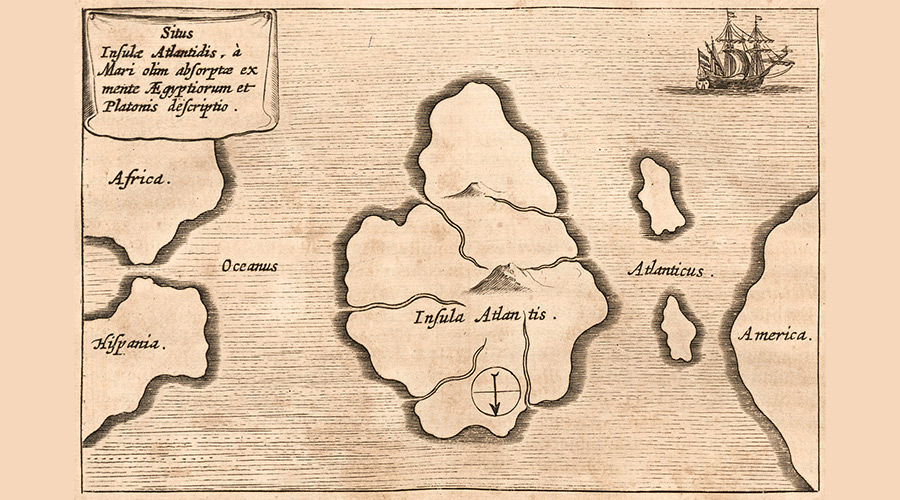

Athanasius Kircher's map of Atlantis, placing it in the middle of the Atlantic Ocean, from Mundus Subterraneus, 1669. Will people pore over maps of the Maldives in the same way?

The presumption by many is that it’s only the young who feel anxious about climate change, for it is they who will inherit the mess. However, according to recent ONS statistics, the middle-aged and the old are almost as worry-weary as young people.

Having analysed a recent ONS Opinions and Lifestyle Survey, straw specialist firm Drinking Straw filtered some of the stats. They reveal that 62% of UK people over the age of 16 worry that rising temperatures will directly affect them by 2030. Of these, 70% of 16-29 year olds were worried about the heat, but 59% of 50-69 year olds were also worried, as were 57% of those aged 70 and over.

In other areas, the differences were even less stark. When it came to anxiety over extreme weather events, 48% of all adults were worried – only slightly less than the 49% of 16 to 29 year olds who did so.

>> How can I make my garden more sustainable? Professor Geoff Dixon shows us how.

Similarly, regarding water supply shortages, 40% of all adults are concerned about them overall, compared to 43% of those aged 16 to 29. Admittedly, young people are more worried than older adults about rising sea levels (45% vs. 31%), but the differences are noticeably narrow in most metrics.

Surprisingly, it turns out the percentage of those who don’t care at all about the merciless heat, parched land, rising sea levels, and freak weather events is fairly consistent across all segments, with the 12% of 16-29 year olds not giving a fig similar to the 14% of indifferent adults.

ONS figures reveal that most people have made climate-friendly changes to their day-to-day lives, whether they grew up in the age of renewables or the age of coal.

Action stations?

Broadly speaking, UK adults are becoming more eco-conscious, if data from the ONS’ Climate change insights, families and households, UK: August 2022 survey are to be believed. The survey has found that 77% of adults have made some, or a lot of changes, to their lifestyles to tackle climate change.

When the remaining 23% were asked why they made no change to their lifestyles, the most common reason given was: the belief that large polluters should make changes before individuals, followed closely by those who felt that individual change wouldn’t make much of a difference.

It’s clear to most of us that the government must help drive change, including on our roads. Despite the UK’s lagging electric vehicle infrastructure, the study revealed that the number of licensed zero emission vehicles, ultra-low emission vehicles, and plug-in vehicles increased by 71% or more last year.

If people knew there were sufficient charging points dotted around their areas – and if they were further incentivised to give up their gas-guzzling vehicles – those numbers would surely increase.

As bleak as the situation is, it is heartening to see our attitudes changing. Now, if you’ll excuse me, I’ve just read a climate-related story that brought a tear to my eye. If anyone wants me, I’ll be weeping in a dark room (passive-cooled, mercifully).

A range of greenhouse gas removal technologies may be necessary if we’re to reach Net Zero by 2050. In the second of our two-part geoengineering feature, Eoin Redahan looks to the sea, the sun, and mineral weathering, and at the ethical concerns such technologies raise. Missed Part One? Find it here.

‘Water, water, everywhere, nor any drop to drink.’

These famous words from Samuel Taylor Coleridge’s Rime of the Ancient Mariner aren’t the only famous part of his epic poem. The term albatross around one’s neck comes from it too.

After shooting a friendly albatross at sea, the poem’s narrator was forced by the ship’s crew to wear the dead creature around his neck – and grievous luck was to follow. Well, our blue planet has an albatross around its neck in the form of climate change.

Perhaps the solution to it lies all around us – water, water, everywhere…

An ocean of potential

In theory, we can use our oceans to pull CO2 from the air on an enormous scale. All it may take is clever intervention – potentially ruinous, albatross-shooting intervention.

Nevertheless, the World Economic Forum lays out the tantalising potential. ‘Ocean-based CO2 removal can help us achieve “net negative emissions” as the seas hold 50 times more carbon than the atmosphere,’ it says.

‘The ocean [is] a sink for nearly one third of anthropogenic carbon emissions and more than 90% of the resulting heat… If we are going to manage atmospheric CO2 levels to our advantage, we will need to leverage the ocean’s existing ability to govern the global carbon cycle.’

Frontier has targeted the development of scalable sources of alkalinity. The reasoning behind it is that with CO2 being an acidic molecule, rising CO2 concentrations could be neutralised through alkalinity. It has mentioned using mine tailings to remove up to 0.5 gigatonnes of CO2 from the air each year; but the major caveat here is that it needs to be done safely.

Planetary Technologies has ventured into this space armed, essentially, with a bicarbonate of baking soda that could draw in CO2 and sequester it for millenia.

The company explains its process: ‘We start by carefully extracting key parts of the mine tailings including recovering battery metals (like nickel and cobalt) and silica (sand) and then take the remaining purified metal salt solution into a special electrolyser. There, using clean, renewable electricity, the salt and water are split to make hydrogen (a clean, emissions-free fuel), and a pure alkaline hydroxide.

‘It’s from this point that we transport the bulk alkaline materials to our ocean outfalls site where the alkalinity is introduced to the surface ocean that then draws in CO2, sequestering it as already abundant bicarbonate and carbonate ions in seawater.’

So, by decreasing the acidity of the ocean, it would have a greater capacity to absorb CO2 from the air. The key, however, is to reduce this to a viable price point.

>> Want to read about iron fertilisation in our oceans? Rhiannon Garth Jones took a closer look here.

Mineral weathering, methane capture, and more

Mineral weathering is another contender in the CO2 removal mix. One technology that recently received $2.4m in funding is Seattle-based Lithos’ enhanced weathering process – a mineral weathering process that could capture CO2 at a gigatonne scale. According to Frontier, Lithos spreads basalt on croplands to increase dissolved organic carbon, before eventually being stored as ocean bicarbonate. The idea is to maximise CO2 removal while bolstering crop growth.

Closer to home, SAC Consulting in Edinburgh will receive £2.9m to capture the methane produced by cattle and cut emissions from the livestock farming sector; Synthetic Biology in San Francisco has received an R&D grant to synthesise a polymer within algae that is capable of sequestering atmospheric CO2 at a large scale; and Charm Industrial is converting plants into a carbon-rich liquid that is pumped underground.

To do the latter, Charm grows cellulosic biomass that captures CO2 from the atmosphere. It is then harvested, ground, and heated, before being turned into a bio-oil that is pumped underground.

Even the concrete beneath our feet could be used as a carbon sink. CarbonCure is injecting CO2 into its concrete mixes, which it says is not only comparable in cost to traditional concrete, but stronger.

And then, we have solar engineering – arguably the first technology that comes into many of our minds when we think of carbon removal. All sorts of geoengineering technologies exist in this sphere including cirrus cloud thinning, stratospheric aerosol scattering, and marine cloud brightening.

Ethical issues?

Interestingly, Harvard’s Solar Geoengineering Research Programme referred to geoengineering as ‘a set of emerging technologies that could manipulate the environment and partially offset some of the impacts of climate change’.

Therein lies the problem for many. What are the consequences of ‘manipulating the environment’, especially if these technologies fall into unscrupulous hands?

In her excellent blog for SCI on geoengineering, Rhiannon Garth-Jones referred to the Haida Corporation Salmon trial. In this trial, 120 tonnes of iron compound were deposited in the migration routes of pink and sockeye salmon in the Pacific Ocean, which resulted in a several-month-long phytoplankton bloom.

It was seen by many as a success. The phytoplankton fed fish and increased biodiversity and the iron sequestered carbon; but Environment Canada believed the corporation violated national environmental laws by depositing iron without a permit.

History teaches us that profit vs. planet tussles don’t always go the way we would like, and the consequences of these technologies going into the wrong hands could be catastrophic.

On 29 June, The World Economic Forum called for a code of conduct for ocean-based CO2 removal; and the American Geophysical Union, a group of climate and planetary scientists, is leading the way in developing an ethical framework for climate intervention engagement.

We’re all feeling the effects of climate change. As I write this piece on 19 July, it is 39°C here in Greenford, London. 39°C in London! The earth is cracking, planes are circling (because the runways are melting), and grass fires are blazing in Croydon.

On days like today, it feels like we need all the innovation we can get.

Many believe that greenhouse gas removal technologies will be necessary if we’re to reach net zero by 2050. In the first of our two-part geoengineering feature, we look at some of the difference-makers.

This week, a friend of mine played a tennis match just north of London. The game was due to take place at 18:00 but was deferred for an hour because it was 39°C. This came a day after Rishi Sunak, who may become the UK’s next Prime Minister, warned about going ‘too hard and too fast’ on net zero measures.

It’s looking increasingly likely that the implementation of environmental policies isn’t happening quickly enough; so, if we want to avoid catastrophic climate change, we will need to develop technologies that pull carbon dioxide from the atmosphere.

Mercury rising: the UK recorded record high temperatures this week.

Certainly, that’s the UK government’s perspective. ‘Greenhouse Gas Removal technology will be essential to meeting the UK’s climate change target of net zero carbon emissions by 2050,’ it said. ‘These technologies will be necessary to offset emissions from hard to decarbonise areas, such as parts of the agriculture and aviation sectors.’

Thankfully, work is underway to make this happen. And it is more than just the pang of the environmental conscience that has stirred the private sector into action. There is much money to be made from geoengineering. Indeed, a CNBC story has estimated that it could be a trillion dollar market by 2050.

The public investment has been relatively modest by some. The UK government recently pledged £54m in funding towards 15 different carbon removal technologies. But some in the private sector have dollar signs in their eyes.

A collaborative called Frontier – funded by Stripe, Alphabet, Shopify, Meta, McKinsey, and tens of thousands of businesses using Stripe Climate – has made an advance market commitment to spend an initial $925m on permanent carbon removal technologies between 2022 and 2030.

‘Models project that by 2050 we will need to permanently remove billions of tons of CO2 from the atmosphere every year,’ it states. ‘To date, fewer than 10,000 tons have been removed in total.’ The capital it has committed is designed to help companies developing carbon removal solutions to scale up.

The UK government has mentioned the need for a portfolio of carbon removal technologies to reach net zero. A cursory look reveals that there are many from which to choose, including direct air capture, the manipulation of the sea, advanced weathering, and solar engineering.

These methods are audacious, exciting, and controversial.

Direct air capture

The key, as ever, is to come up with low-carbon technologies that are both effective and economically viable. In that respect, direct air capture has emerged as a front runner. This technology often uses giant fans with filters, or chemical processes, to take CO2 from the air.

The difficulty is the amount of energy needed to power these processes and the source of this energy. The cost of removing each tonne of CO2 is also an impediment to growth – something that will need to fall for it to be implemented on a large scale.

Climeworks co-founders Jan Wurzbacher and Christoph Gebald at the Orca plant in Iceland. Image courtesy of Climeworks.

Nevertheless, significant strides have been made in recent times. Swiss company Climeworks raised US$650m in equity for its largest direct air capture plant, and last week it inked a 10-year deal with Microsoft to permanently remove 10,000 tonnes of CO2 emissions from the atmosphere on its behalf.

The company’s machines capture CO2 from ambient air by drawing air into the collector with a fan. The CO2 is captured on the surface through a selected filter material that sits inside the collectors. Once the filter is filled with CO2, the collector is closed, and the temperature is increased to 80–100°C, whereupon the CO2 is released.

And what becomes of the CO2 after that? The CO2 at its Orca facility (50km outside Reykjavík, Iceland) will be mixed with water and pumped deep underground. The carbon dioxide will then react with the basalt rock through natural mineralisation and turn into stone.

Climeworks CO2 turned into stone via Carbfix technology. Image courtesy of Climeworks.

And Climeworks isn’t the only one operating in this space. As part of the UK Government’s aforementioned £54m funding, London-based Mission Zero Technologies will receive £2.9 million to build a low-energy, heat-free way to pull CO2 from the air.

Sydney-based AspiraDAC has been backed by the Stripe Climate Fund to remove 500 tonnes of CO2 using its modular, solar-powered system. According to Frontier: ‘Its MOF (metal-organic framework) sorbent has low-temperature heat requirements and cheap material inputs, increasing the likelihood that AspiraDAC can help accelerate the production of lower-cost metal-organic frameworks which, historically, have been expensive and difficult to synthesise.’

The Stripe Climate Fund has also backed 8 Rivers Capital, LLC, and Origen Carbon Solutions, Inc to remove CO2 from the air using its direct air capture (DAC) technology. Frontier said: ‘The DAC technology accelerates the natural process of carbon mineralisation by contacting highly reactive slaked lime with ambient air to capture CO2. The resulting carbonate minerals are calcined to create a concentrated CO2 stream for geologic storage.’

Of course, direct air capture is just one of many CO2 removal solutions. In part two, next week, we’ll look at other promising technologies.

What is the verdict on the 100% sustainable fuel Formula 1 plans to use in its cars, and is the new E10 fuel this season doing any good? We asked David Bott, SCI’s Head of Innovation.

Beware of Greeks bearing gifts. This phrase comes from Virgil’s Aeneid, and it refers to the Greeks’ gift of a giant wooden horse to their enemies during the Trojan War. But this was no gift at all.

This warrior-filled, hollow wooden horse that the Trojans wheeled inside the gates of Troy was a ploy from the Greeks to get inside the city’s impenetrable city walls and ambush their enemy. It turned out things weren’t quite what they seemed.

Just as Trojans became wary of giant wooden horses, we should be wary of Net-Zero pledges. These promises seem impressive but, if you look inside, they might not be quite as beneficial to the environment as advertised – at worst, they could be hollow.

Whenever an organisation talks of carbon credits, makes a vague reference to biomass or a grand pledge with little detail, it is worth closer investigation.

Formula 1 recently made a sustainability pledge of its own. Following its decision to use E10 fuel in the cars this season (a mixture of 90% fossil fuel and 10% ethanol), it has announced plans to use a 100% sustainable drop-in fuel in its vehicles as part of its plans to reach Net-Zero by 2030.

On first reading, the terms Net-Zero and Formula 1 don’t sit easily together. Isn’t this the sport where 20 cars can burn more than 100kg of fuel each per race? The same travelling circus in which cars, teams, and drivers are flown and ferried all over the world for more than eight months of racing?

By its own calculation, in a November 2019 report, Formula 1 is responsible for 256,551 tonnes of carbon dioxide emissions each year. To put that figure into perspective, you would need to drive for 6,000km in a diesel car to generate a single tonne of carbon emissions – multiply that by 256,000, and Net-Zero feels some distance away.

What about the E10 and proposed drop-in fuels?

Both Formula 1’s new fuel and pledges merit closer inspection. Regarding the move to the E10 fuel in Formula 1 cars, David Bott, SCI’s Head of Innovation, wasn’t exactly gushing.

‘E10 is an evolutionary backwater – adding just 10% ethanol does nothing for emissions,’ he said. ‘A quick enthalpy calculation shows the energy in the fuel has decreased, so you need more.’

The proposed move to a ‘100% sustainable drop-in fuel’ used in standard internal combustion engines is seen by many as a positive move. Formula 1 says the fuel will be made using components from either carbon capture, municipal waste, or non-food biomass.

Each of these ‘components’ on its own is worth exploration. For example, what types of municipal waste do they mean, which types of non-food biomass are they talking about, and what about the manufacturing process?

Biomass fuel is controversial due to concerns over carbon sequestration and land use.

The passage of time will reveal more but, again, David has questioned the green credentials of the proposed fuel. He said: ‘What Formula 1 is proposing to do is analogous to sustainable aviation fuel – to make octane from a non-fossil source of carbon.’

‘[To do this], you can use biomass or “synthetic”, which basically means distillate plastic waste. It is effectively using fossil carbon that was used for something else; so, it doesn't make the situation any worse, but neither does it really contribute to lowering emissions. It’s just short-cycle carbon.’

Freight with difficulty

The mention of aviation is pertinent when it comes to Formula 1. The emissions generated by the 10 teams’ vehicles across 21 Grands Prix, including races and testing, account for just 0.7% of Formula 1’s total emissions. But by far the biggest contributor to its CO2 emissions are logistics – the movement of equipment from venue to venue by land, sea, and air.

The equipment used in Formula One must be transported from continent to continent by sea, land, or air.

After that comes business travel at 27.7%, which includes the air and ground transportation of all individuals, as well as the hotel footprint from all Formula 1 teams’ employees and major event staff. So, it’s clear that the main environmental problem isn’t the fuel used during the races; it is all of the other transport emissions.

To be fair to Formula 1, the sport has made an effort to make operations greener, including powering its offices using 100% renewable energy and taking measures to make freight more efficient.

However, any claims that it is motoring to Net-Zero by 2030 need to be chased with a liberal swig of scepticism. A Net-Zero 2030 goal provides a nice headline, but how you get there is the story.

Johnson Matthey has launched a technology to help create a green hydrogen-based aviation fuel, while the European Commission has approved a €900 million scheme (£750 million approximately) to support renewable hydrogen investments.

SCI Corporate Partner Johnson Matthey has developed HyCOgen to convert CO2 and green hydrogen into a scalable and sustainable aviation fuel (SAF). The speciality chemicals company says it has combined this Reverse Water Gas Shift technology with FT CANS Fischer Tropsch technology through a catalysed process. With this approach, the green hydrogen and CO2 are converted into carbon monoxide, which is combined with additional hydrogen to form syngas.

Integration with the FT CANS technology is used to turn 95% of the CO2 into a high quality synthetic crude oil. This synthetic crude oil can then be upgraded into sustainable, drop-in fuel products for aviation transport – a sector responsible for 12% of transport-related CO2 emissions, according to the Air Transport Action Group.

Green hydrogen fuel, produced using renewable energy, could help decarbonise the aviation industry.

Jane Toogood, Sector Chief Executive at Johnson Matthey, said: “Given the challenges associated with new propulsion technologies and airport infrastructure, plus the long asset life of aircraft, there are significant hurdles in moving from hydrocarbon-based aviation fuel to alternatives such as battery electric or hydrogen.

“By combining HyCOgen with FT CANS, we can now deliver customers a cost-efficient, reliable and scalable technology to help increase SAF production, backed by our track record of successful technology development and commercialisation.”

>> Concerned about climate change? Find out what you can do in this free webinar: https://www.soci.org/events/hq-events/2022/why-we-ignore-climate-change-and-what-we-can-do-about-it

€900 million fund for non-EU countries

In other hydrogen-related news, the global hydrogen industry has received a boost with the European Commission approving a €900 million German scheme to support investments in renewable hydrogen production in non-EU countries.

The aim of the H2Global project is to meet the growing EU demand for renewable hydrogen production, which is expected to increase significantly as EU countries reduce their reliance on fossil fuels. Even though the initiative will benefit EU countries, UK-based organisations concerned with hydrogen power could benefit from this investment.

>> Young chemists are getting creative in the fight against climate change. Read more in our COP26 review blog.

Margrethe Vestager, the European Commissioner for Competition who is in charge of competition policy, said: “This €900 million German scheme will support projects leading to substantial reductions in greenhouse emissions, in line with the EU’s environmental and climate objectives set out in the Green Deal.

“It will contribute to addressing the increasing demand for renewable hydrogen in the Union, by supporting the development of this important energy source in areas of the world where it is currently not exploited with a view to importing it and selling it in the EU. The design of the scheme will enable only the most cost effective projects to be supported, reducing costs for taxpayers and minimising possible distortions of competition.”

Our careers often take us in unforeseen directions. Dr Jessica Jones, Applications Team Leader at Croda, chatted to us about moving from research into management, the benefit of developing softer skills, and her unexpected mentor.

Tell me about your career to date.

I came through university in what is probably seen as the ‘traditional’ way. I did a Master’s degree in chemistry at the University of Liverpool, with a year working in industry, which I really enjoyed. And then after I finished my Master’s, I did a PhD in Inorganic Chemistry at the University of Nottingham. I always wanted to work in industry, but I really enjoyed research, so I decided to do the PhD as I thought the skills would be useful for either career path.

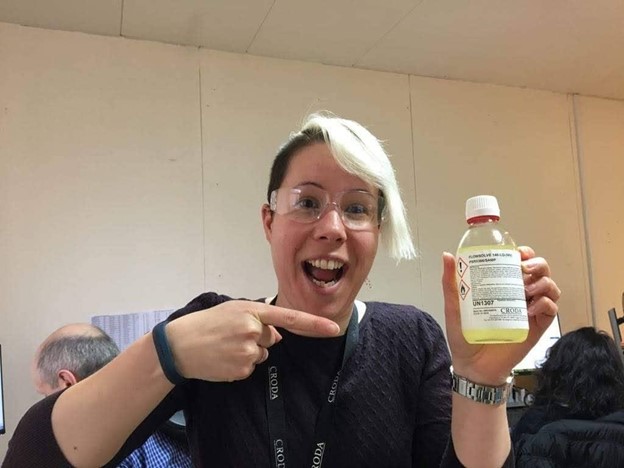

Jessica Jones in the lab

Were you tempted by a career in academia?

No, I never felt like I was the kind of person who had what it takes to succeed in academia. I never felt like I could ever come up with the nucleus of a new idea. I always felt like someone could give me the slimmest thread of a thought and I could turn it into something, but I could never have that thread myself. From my perspective, academia can be a lonely career and I enjoy and benefit from working in a team with other people.

So, after I finished my PhD, I joined Croda in 2013 as a Research Scientist in our synthesis division, in a synthetic chemistry R&D role. Over seven years, I progressed from Research Scientist to Lead Research Scientist and then Team Leader. During that time, I moved around a bit. I worked at different manufacturing sites, in different research areas and did lots of different projects across multiple sectors.

In February 2020, I was asked if I wanted to go on secondment, as a Team Leader, to one of our applications teams in Energy Technologies. Energy Technologies focuses on lubricants, oil and gas, and batteries. I really enjoyed the secondment and after it came to an end, I chose to take it on as a permanent position rather than return to my old role.

What does this role entail?

My role entails managing a team of application and lead application scientists who work on a range of projects, from designing new products to supporting customers with specific problems and working with universities on more theoretical, developmental ideas.

At the moment, we’re working on a lot of what we call EV (electric vehicle)-friendly fluids. When you move from traditional combustion engines to electric vehicles, there’s quite a change in the properties needed for the fluids within the engine. We make the speciality additives that go into the base oils that support functions such as reduced engine wear and improved fuel efficiency.

The EV market is very different to the traditional car market, which is dominated by big lubricant manufacturers. EVs are so new that Croda has been at conception discussions with world leading EV companies. The whole sector is very data driven and, coming from a research scientist background, that appeals to me very much. It’s very exciting to be at the cutting-edge of innovation with what we’re doing within electrification and renewable energy.

Which projects are you working on at the moment?

I’ve got two long-term new development projects that are both progressing to the final stages of manufacturing. These are products that I designed the chemistry for when working in the synthesis team. It can take four or five years to get a new project through the development process, and I’ve continued to manage them throughout their timeline, even though I have moved into different roles. They are both speciality additives for crude oil to reduce the temperature at which impurities develop, to allow the more difficult oil fractions to be brought out of the ground without it solidifying in pipes when they transport it.

What does a general working day involve?

There are eight people in our team, and I am responsible for managing six of them. There are two other senior technical specialists I work alongside. They have lots of experience in the industry and working with academia, and the three of us coordinate the projects across the team.

My role is to translate the pipeline and the strategy from our senior leaders into what we do in the lab every day. I have three projects that I'm running, which are new product launches. Alongside that, I coordinate the project pipeline and make sure everyone is able to manage their projects and progress them. I do a small amount of lab work, but I would say it makes up 5% of my time.

I always thought I would be a specialist when I joined Croda because of my PhD and lab experience. However, over the time I’ve worked here, I started to really enjoy working with other people; and I think I probably realised I had better skills at motivating other people, building up teams, and networking. So that became a lot more important, and I chose to move into the management side of things but still within a technical function.

Interpersonal skills are sometimes underrated in management. How do you approach this side of the job?

I think I am quite at ease around other people as I am very extroverted. I think that makes me different from a lot of people in my team. For example, my boss and I are the total opposite of each other, but it works really well because it means that we complement each other perfectly. He’s very strategic and he likes to take his time to make decisions. He likes to review all the data very methodically and is good at using detail to evaluate a project’s true value, whereas I’m much more about talking to people, bringing everyone together and acting quickly to get things done. But I think the balance of both works incredibly well for us as a team.

During lockdown we received a webinar on personal resilience, and the session was about your outward projection to other people. About 70% of how you are perceived by others is made up of how people see you and your ‘brand’. Your technical expertise and actual ability to do your job only makes up about 20% of how people view you and how successful you are. And I think as a scientist, you get a bit focused on delivering the project successfully, thinking that you need to be really amazing at delivering data, but people forget about the need to work on themselves to develop as well.

What part of your job motivates you most?

It’s a combination. The science we’re working on is very exciting, and I really enjoy getting all the projects together, making sure everything fits together and that everyone’s doing the right thing. But emotionally, it’s the team that gets me up in the morning – coming in, seeing what they do, how they have been. I’ve been really lucky over the past 12 months, being able to see some of my colleagues really develop. I’ve taken a lot of pride in realising the impact you can have on other people and allowing yourself to take credit for that.

>> What is life like as a materials scientist? Take a look at our thought-provoking conversation with Rhys Archer, founder of Women of Science.

Which mentors have helped you along the way?

There’s one person who stands out. I was asked to take on this extra role to become a European technical rep in one of our business areas. I’d never done anything like that before so the idea that I was going to be put out there, in front of customers, as the technical expert for the business was quite terrifying.

I was to work with the European Sales Manager of the business, and we ended up traveling a lot together. He was the opposite to me. He’s very experienced but had a reputation as a bit of a loud, burly Yorkshireman and I wasn’t sure how we would fit together, but we got on like an absolute house on fire. He was so helpful to me, not just in giving feedback on what I was doing in the role, but general conversations about career and life outside of work and personal support. Having that kind of professional relationship develop has made a massive difference. Just meeting someone like that and having a person to go to when I needed help, someone who I really trust to have my best interests at heart. It was very beneficial for the number of years that we worked together. Since then, we have moved on to different roles, but we still stay in touch, and it has taught me the value in reaching out to different people to help me to develop.

Jessica with the first product she developed at Croda.

In terms of equality and diversity, do you think enough is being done in your sector?

I think there is always more that can be done but I’ve never felt my gender has hindered me in my career and I’ve always felt very supported at Croda. Sometimes people are in a rush to see change immediately, especially when the senior management at Croda and many other STEM organisations is still made up of a majority of white males.

I like to think that the support myself and others have been given will mean that, as we progress, there will be more representation in senior positions. I would always want to achieve something on merit rather than to tick a box for equality. If that means it will take time for the generation I am in now to get to those positions, then I can wait. Importantly, I genuinely think everything that’s being put in place at Croda, and more broadly across the STEM sector, will pave the way for more diverse representation in senior roles in the future.

Do you have any advice you’d give to someone starting out?

Having a mentor is very important. I never thought I needed one until accidently developing that relationship. Since moving into different roles, I’ve set out to deliberately engage with people for that purpose. I would encourage people to seek out those who are different from themselves and engage with them.

I also think it’s important not to be afraid to ask for things you want. If you want to get a promotion or seek out further development, it’s often tempting to ask permission. If you can demonstrate to people that you are ready, it is more effective.

Generally, I think people, especially women, really underestimate the value of self-promotion as they worry it can be perceived as arrogance. A lot of people think that if you simply do a good job, then you’ll be recognised for that. That would be amazing if it were true, but people will judge you on how you’re perceived and how you present yourself, as well as what you do.

I think you need to put yourself out there. Whether it’s getting involved in something outside of your day job or taking the lead in a particular task, it’s a great way to get recognised. Sometimes it won’t work out and it can be hard to take the criticism when that happens, but you always learn from the outcome. I always prefer to have given something a go, even if I fail, than never to try.

Finally, I think people should always be themselves because everyone has unique skills to offer. I don’t think people would look at me and think that I look like the manager of a technical team, but I’m comfortable with my own style and that makes other people comfortable with it too.

>> We’re always interested in hearing about different people’s diverse career paths into chemistry. If you’d like to share yours, get in touch with us at: eoin.redahan@soci.org

A completely clean, renewable energy system that can be produced locally and that can easily power heat, energy storage and transportation, and travel — that's the future that promoters of a hydrogen economy envisage.

If it sounds a bit like rocket science, that's because it is. Hydrogen is what's used to fuel rockets — that’s how powerful it is. In fact, it’s three times more powerful as a fuel than gas or other fossil-based sources. And, after use, it’s frequently converted to drinking water for astronauts.

US President Joe Biden has highlighted the potential of hydrogen in his ambitious plans for economic and climate recovery and a number of recent reports have been encouraging about hydrogen’s breakthrough moment, including McKinsey and Company (Road Map to a US Hydrogen Economy, 2020) and the International Energy Agency.

Hydrogen fuel cells provide a tantalising glimpse into our low-carbon future

The McKinsey report claims that, by 2030, the hydrogen sector could generate 700,000 jobs and $140bn in revenue, growing to 3.4 million jobs and $750bn by 2050. It also believes it could account for a 16% reduction in CO2 emissions, a 36% reduction in NOx emissions, and supply 14% of US energy demand.

So how does it work?

Simply put, hydrogen fuel cells combine hydrogen and oxygen atoms to produce electricity. The hydrogen reacts with oxygen across an electrochemical cell and produces electricity, water, and heat.

This is what gets supporters so excited. In theory, hydrogen is a limitless, incredibly powerful fuel source with no direct emissions of pollutants or greenhouse gases.

So what's the problem?

Right now, there are actually a few problems. The process relies on electrolysis and steam reforming, which are extremely expensive. The IEA estimates that to produce all of today’s dedicated hydrogen output from electricity would require 3,600TWh, more than the total annual electricity generation of the European Union.

Moreover, almost 95% of hydrogen currently is produced using fossil fuels such as methane, natural gas, or coal (this is called "grey hydrogen"). Its production is responsible for annual CO2 emissions equivalent to those of Indonesia and the United Kingdom combined. In addition, its low density makes it difficult to store and transport — it must be under high pressure at all times. It’s also well-known for being highly flammable — its use as a fuel has come a long way since the Hindenburg Disaster but the association still makes many people nervous.

A Hydrogen refuelling station Hafencity in Hamburg, Germany. Infrastructure issues must be addressed if we are to see more hydrogen-fuelled vehicles on our roads. | Image credit: fritschk / Shutterstock.com

So there are quite a few problems. What’s the good news?

In the last few years, we've seen how rapidly investment, innovation, and infrastructure policy can completely transform individual renewable energy industries. For example, the IEA analysis believes the declining costs of renewables and the scaling up of hydrogen production could reduce the cost of producing hydrogen from renewable electricity 30% by 2030.

Some of the issues around expense could be resolved by mass manufacture of fuel cells, refuelling equipment, and electrolysers (which produce hydrogen from electricity and water), made more likely by the increased interest and urgency. Those same driving forces could improve infrastructural issues such as refuelling stations for private and commercial vehicles, although this is likely to require coordination between various stakeholders, including national and local governments, industry, and investors.

The significant gains in renewable energy mean that “green” hydrogen, where renewable electricity powers the electrolysis process, is within sight.

The IEA report makes clear that international co-operation is “vital” to progress quickly and successfully with hydrogen energy. R&D requires support, as do first movers in mitigating risks. Standards need to be harmonised, good practice shared, and existing international infrastructure built on (especially existing gas infrastructure).

If hydrogen can be as efficient and powerful a contributor to a green global energy mix as its proponents believe, then it's better to invest sooner rather than later. If that investment can help power a post-Covid economic recovery, even better.